12-107

95-2 SERIES

TROUBLESHOOTING S-1

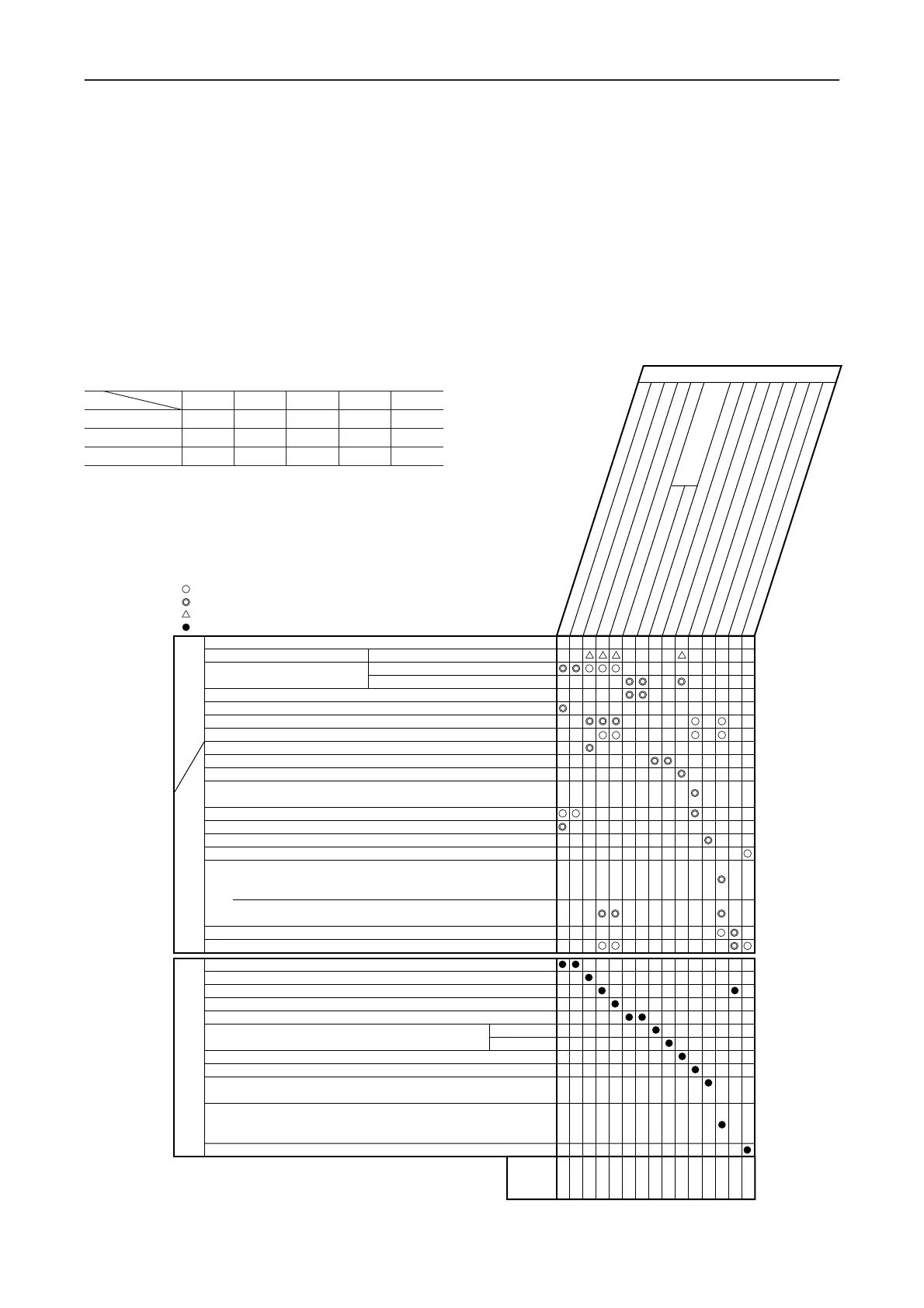

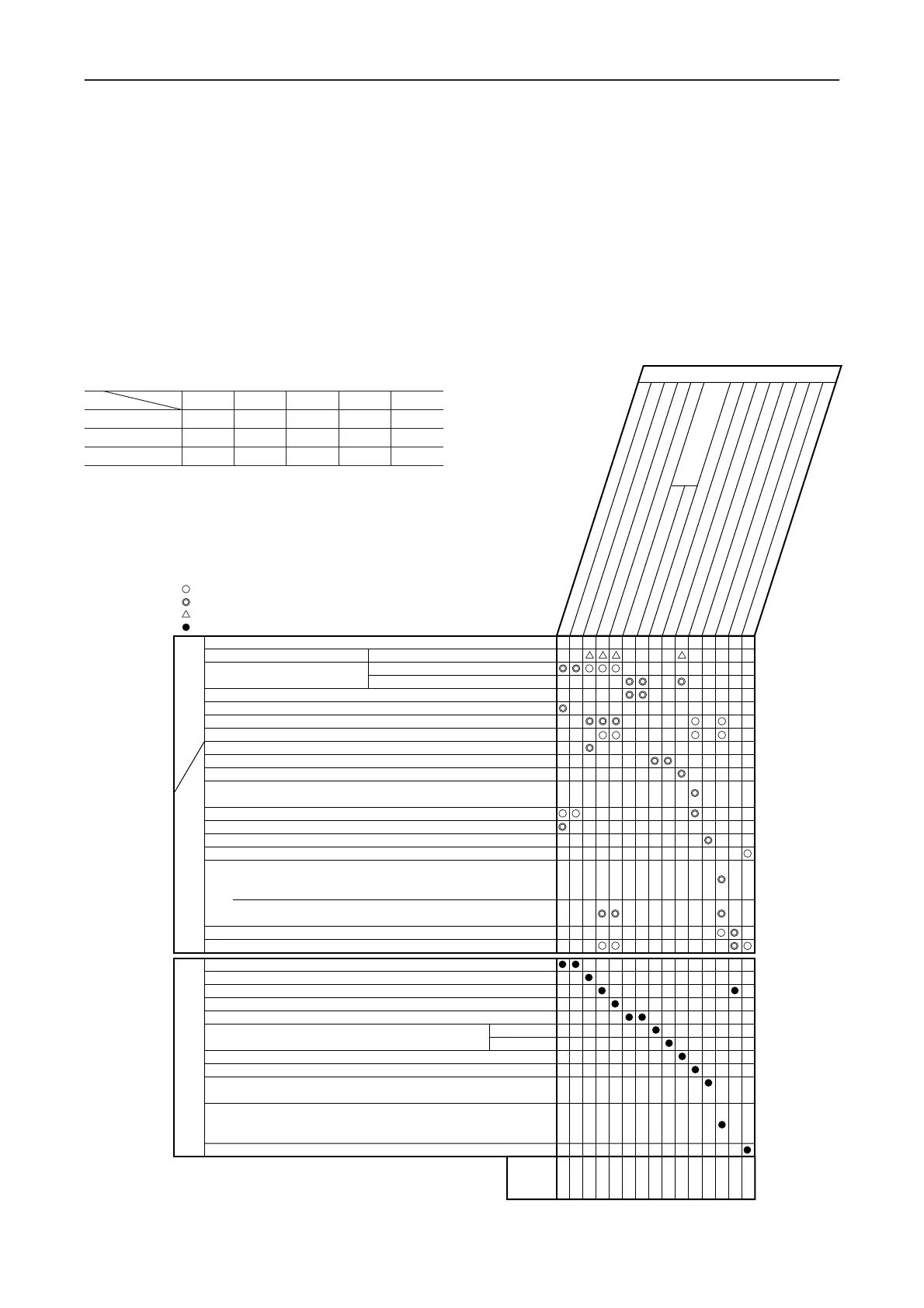

S-1 Starting performance is poor (starting always takes time)

fl Check that the monitor panel does not display any

abnormality in the governor control system.

General causes why exhaust smoke comes out but

engine takes time to start

• Defective electrical system

• Insufficient supply of fuel

• Insufficient intake of air

• Improper selection of fuel

(At ambient temperature of 10˚C or below, use

ASTM D975 No. 1)

fl Battery charging rate

100% 90% 80% 75% 70%

20°C 1.28 1.26 1.24 1.23 1.22

0°C 1.29 1.27 1.25 1.24 1.23

–10°C 1.30 1.28 1.26 1.25 1.24

Charging rate

Ambient tem-

perature

• The specific gravity should exceed the value

for the charging rate of 70% in the above table.

• In cold areas the specific gravity must ex-

ceed the value for the charging rate of 75%

in the above table.

Confirm recent repair history

Degree of use of machine

Ease of starting

Indicator lamp does not light up

Engine oil must be added more frequently

Replacement of filters has not been carried out according to Operation Manual

Non-specified fuel is being used

Dust indicator is red

Battery charge lamp is ON

Starting motor cranks engine slowly

When exhaust manifold is touched immediately after starting

engine, temperature of some cylinders is low

Engine does not pick up smoothly, and combustion is irregular

Blow-by gas is excessive

Match marks on fuel injection pump are out of alignment

Mud is stuck to fuel tank cap

When engine is cranked with starting motor,

1) Little fuel comes out even when fuel injection pipe

sleeve nut is loosened

2) Little fuel comes out even when fuel filter air bleed

plug is loosened

Leakage from fuel piping

There is hunting from engine (rotation is irregular)

Worn piston ring, cylinder

Defective contact of valve, valve seat

Clogged air cleaner element

Clogged fuel filter, strainer

Clogged feed pump strainer

Electrical intake air heater

Glow plug

Defective regulator

Defective alternator

Defective or deteriorated battery

Defective fuel injection nozzle

Defective fuel injection timing

Defective fuel injection pump (rack, plunger stuck)

Leakage, clogging, air in fuel piping

Clogged air breather hole in fuel tank cap

Auxiliary

starting system

Questions

When compression pressure is measured, it is found to be low

When air cleaner element is inspected directly, it is found to be clogged

When fuel filter, strainer are inspected directly, they are found to be clogged

When feed pump strainer is inspected directly, it is found to be clogged

Glow plug mount does not become warm

Is voltage 26 – 30V between alternator terminal

B and terminal E with engine at low idling?

Either specific gravity of electrolyte or voltage of battery is low

Speed does not change when operation of certain cylinders is stopped

When check is made using delivery method, injection timing

is found to be incorrect

When control rack is pushed, it is found to be heavy or does

not return (when blind cover at rear of pump is removed, it

can be seen that plunger control sleeve does not move)

When fuel cap is inspected directly, it is found to be clogged

Troubleshooting Check items

Causes

Operated for long period

Gradually became worse

Starts when warm

Yes

No

Remedy

Replace

Correct

Clean

Clean

Clean

Replace

Replace

Replace

Replace

Replace

Replace

Adjust

Replace

Correct

Clean

Legend

: Possible causes (judging from Questions and check items)

: Most probable causes (judging from Questions and Check items)

: Possible causes due to length of use (used for a long period)

: Items to confirm the cause

12-107

1

Loading...

Loading...