©

B

R

E

A

T

H

E

S

A

F

E

2

0

1

9

www.breathe-safe.com.au

Page

8

Issue date:

Controlled document:

Revision:

WA900-3EO

The components, which combine to make up

the air conditioning system, are in four dierent

circuits as under:

» Air Circuit

» Refrigeration Circuit

» Heating Circuit

» Electrical Circuit

AIR CIRCUIT

The evaporator section has a basic air

recirculation circuit provided by two forward

curved fans in parallel. These blow air through

the evaporator and deliver the conditioned air

into the cab.

Average cab temperature is controlled by a

thermostat, the capillary of which senses the

temperature of the coil.

A second circuit is created by the addition of a

lter / pressuriser. If tted this consists of two

stages of ltering, followed by a single stage

pressurising fan with the ltered fresh air being

mixed with cab return air before passing over the

heat exchange coils.

Depending on the model of condenser, the

condenser air is provided by either one axial

(propeller) ow fan and drawn through the

bottom of the condenser coil and discharged

through the top of the condenser. Or the

condenser air is provided by three axial fans

and drawn through the top of the condenser and

discharged over the condenser coil.

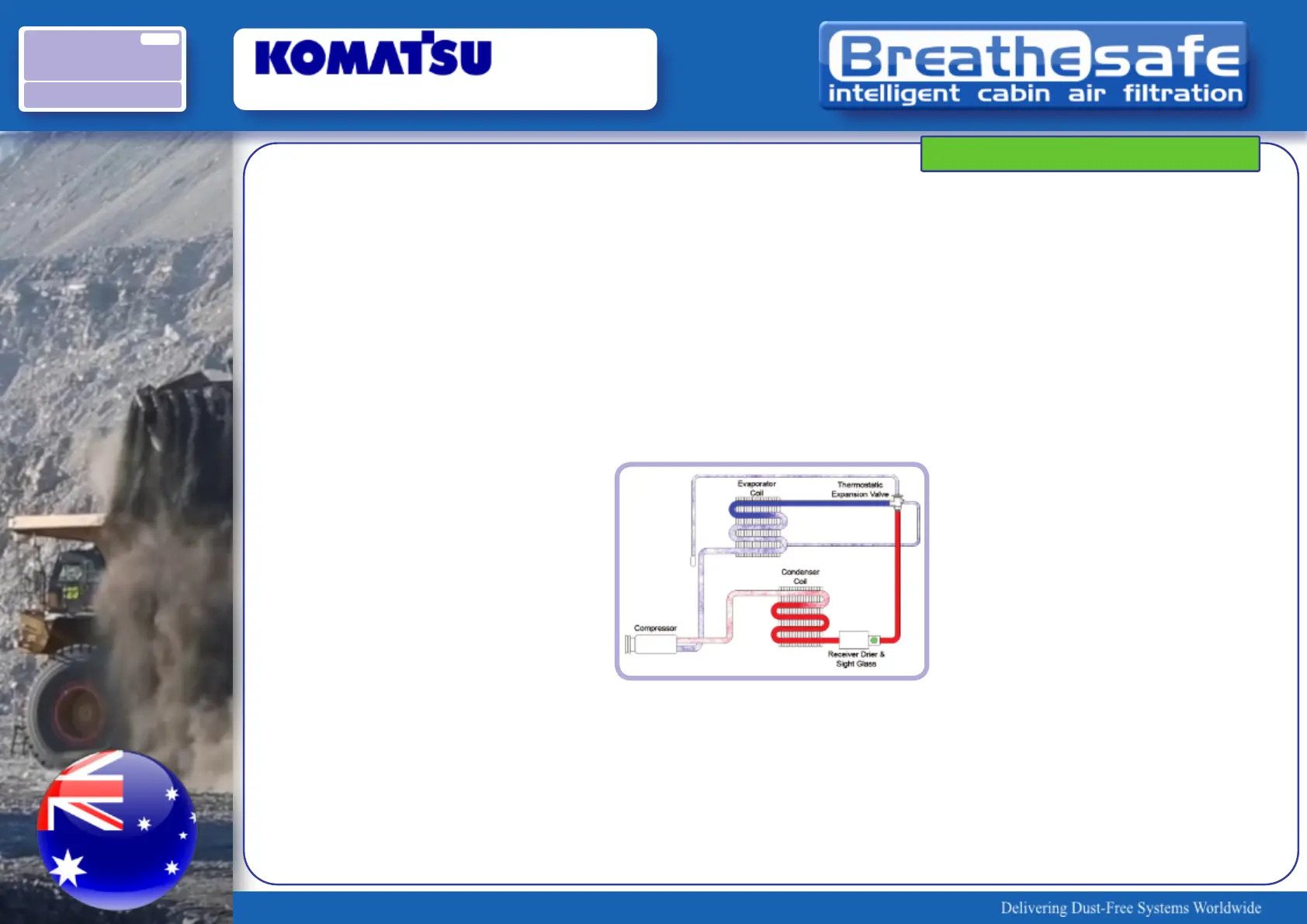

REFRIGERATION CIRCUIT

To illustrate the change of state of the

refrigerant as it travels through the system, the

descriptions of the refrigeration components

have been listed in the order which coincides

with refrigerant ow.

1. Condenser Coil

Condensing of the refrigerant is the change

of state of the refrigerant from a vapour to a

liquid. The condenser

receives the high pressure, high

temperature refrigerant vapour from the

compressor and condenses it to a high

temperature liquid. The liquid refrigerant

then ows to the receiver drier.

2. Receiver Drier

The receiver drier utilised in these units is

of fully welded construction, tted with an

integral sight glass. The receiver drier

serves as a reservoir for the storage of high

pressure liquid produced in the condenser.

It also functions as a lter/drier by means

of a dehydrating agent combined with

ltration system to trap minute particles of

moisture and foreign material which may

have entered the refrigeration system.

3. Thermostatic Expansion Valve

The expansion valve is located on the

evaporator inlet line and provides the

functions of throttling and controlling the

ow of liquid refrigerant to the evaporator

coil. This refrigerant ow is restricted

creating a pressure drop across the valve.

Thus, the refrigerant that enters the valve

as a hot high pressure liquid exits it as a

cold low pressure liquid.

The ow rate will vary according to the

heat load, sensed by the diaphragm

capillary, and the suction pressure at the

evaporator.

PRINCIPALS OF AIR CONDITIONING

OVERVIEW

Loading...

Loading...