5-7

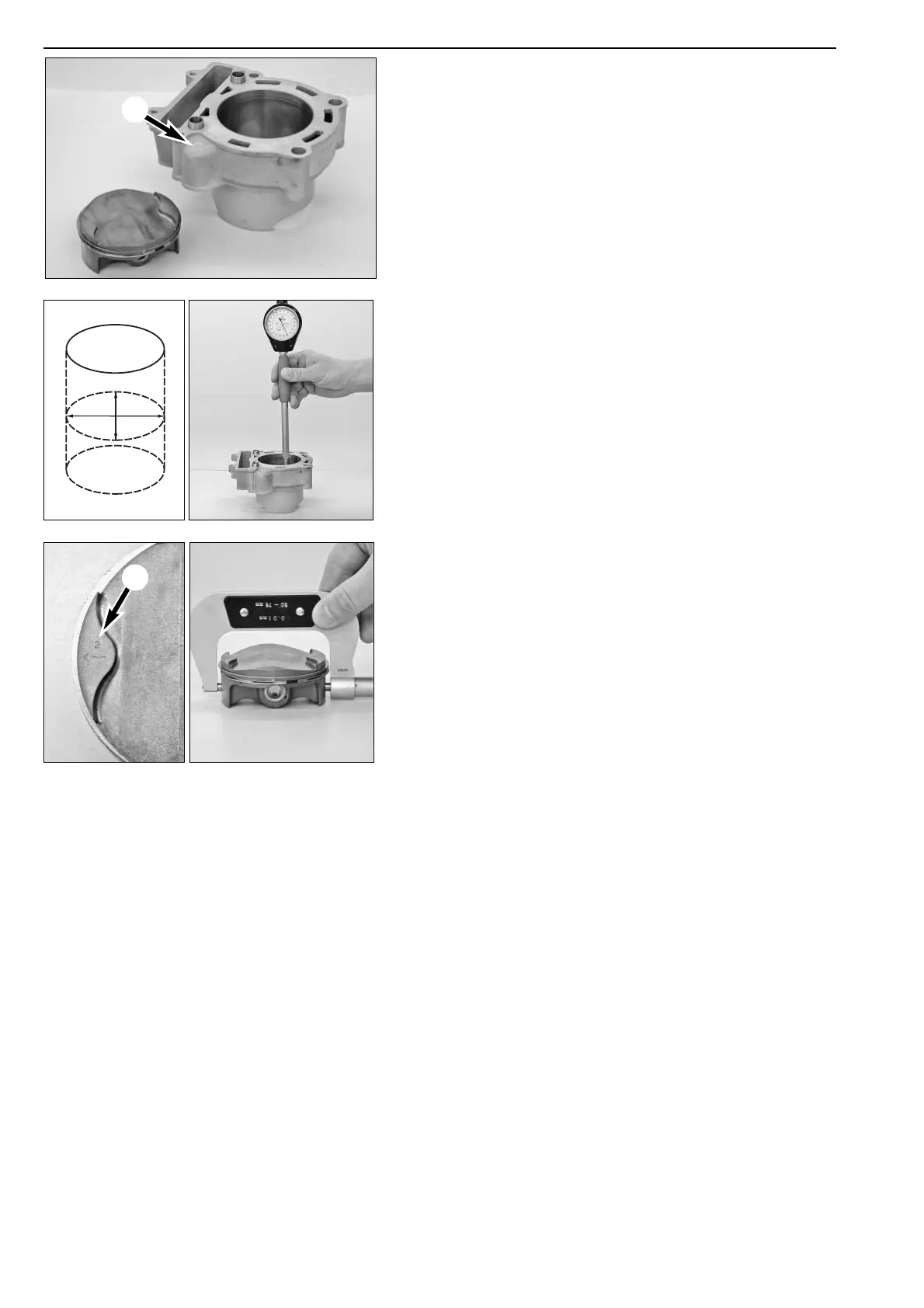

Nikasil cylinder coating

Nikasil is the brand name for a cylinder coating process developed by

the Mahle piston company. The name is derived from the two materials

used in the process - one layer of nickel in which the exceptionally

hard silicon carbite is embedded. The major advantages of the Nikasil

coating include its outstanding heat dissipation and the improved

power output, the insignificant wear and low weight of the cylinder. It

is inexpensive to repair (replace) a worn coating if the cylinder barrel is

not damaged.

Measuring the piston and cylinder, establishing the mounting

clearance of the piston

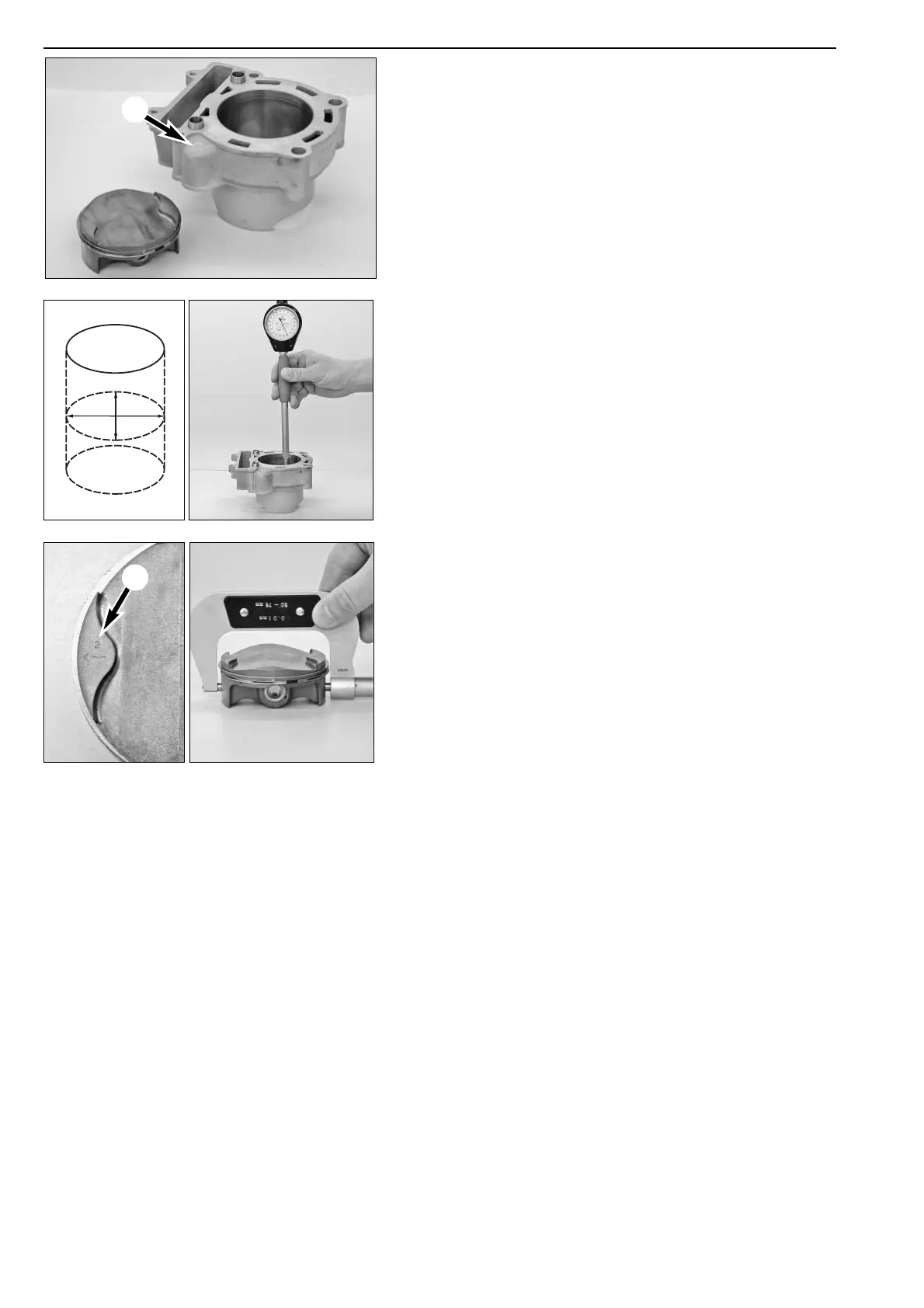

– To establish the wear to the cylinder, use a micrometer to measure

the cylinder in the middle of the bearing surface.

– Measure the diameter of the cylinder in the X and the Y axis to

detect any ovality.

Cylinder diameter Size I: 76.000 - 76.012 mm

Size II: 76.013 - 76.025 mm

NOTE: mark the cylinder size

1 on the side of the cylinder, the piston

size

2 on the piston head.

– The piston is measured at the piston skirt across the piston pin, as

illustrated.

Piston diameter Size I: 75.960 - 75.970 mm

Size II: 75.971 - 74.980 mm

– The piston mounting clearance is the difference between the

smallest cylinder diameter and the piston diameter.

Piston mounting clearance Size I: 0.030 - 0.052 mm

Size II: 0.032 - 0.055 mm

Wear limit: 0.070 mm

Loading...

Loading...