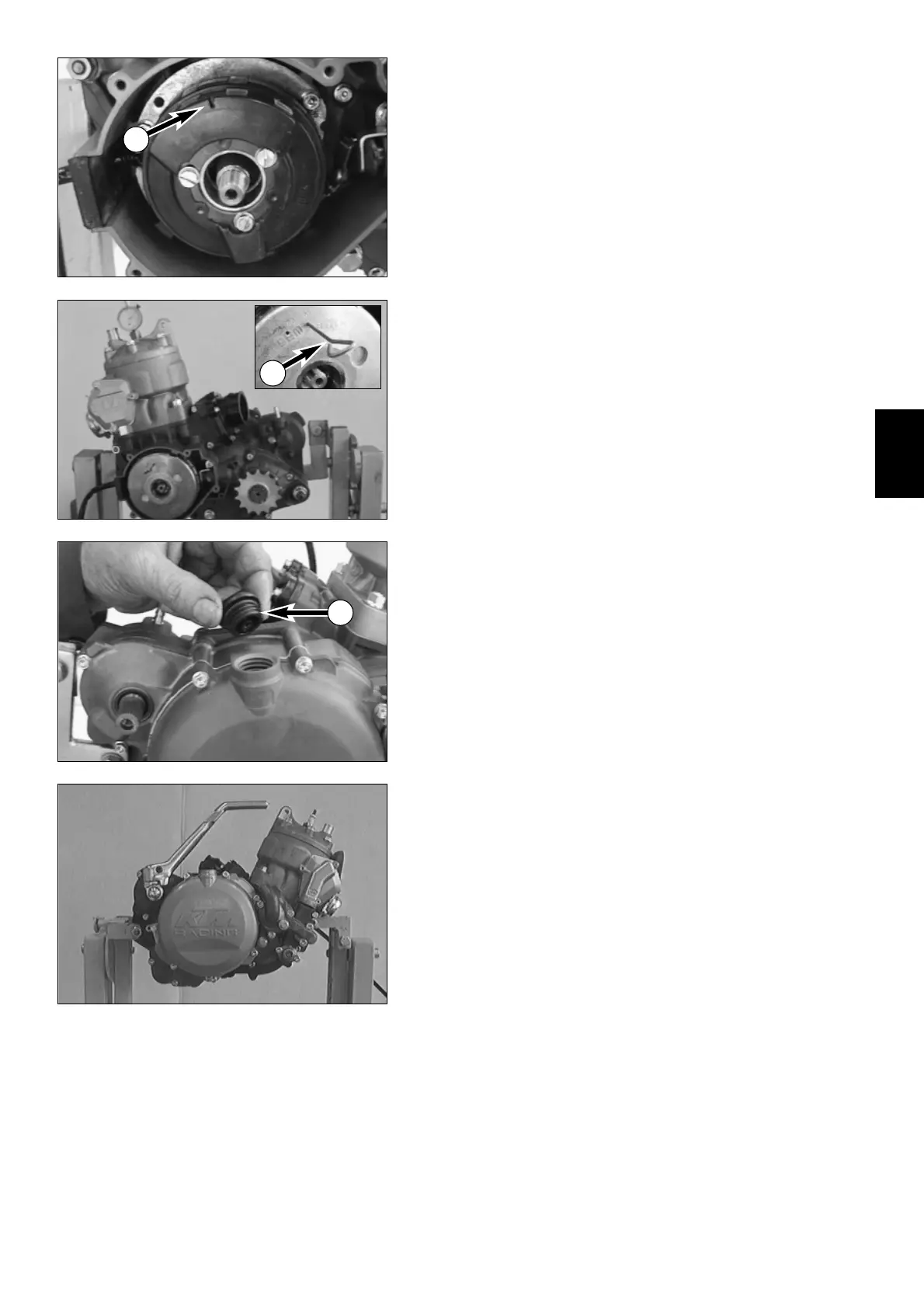

5.19 Adjusting ignition point (SEM)

– Mount flyweel.

– Screw dial gauge into spark plug thread.

– Place adjusting pin

3

in flywheel bore (“91“) 2 mm (0.08 in) and turn flywheel

until pin slots into recess

C

in stator.

– Turn flywheel and stator jointly to TDC.

– Turn dial gauge scale to 0 and turn flywheel with stator clockwise accordingly to

preignition.

I

GNITION POINT

:

250 EGS = 1.2

MM / 0.047 IN (13.5 DEG.) BEFORE TDC.

300 EGS = 1.2

MM / 0.047 IN (13 DEG.) BEFORE TDC.

380 EGS = 1.4

MM / 0.055 IN (13 DEG.) BEFORE TDC.

– Carefully remove flywheel to prevent further turning of stator.

– Tighten the three stator cylinder screws.

– Mount flywheel and tighten collar nut with 60 Nm (45 ft.lb).

– Check ignition point once more.

– Remove dial gauge and fit spark plug with OR.

– Hook clutch cable to release lever.

– Mount gasket and fix ignition cover with 5 collar screws.

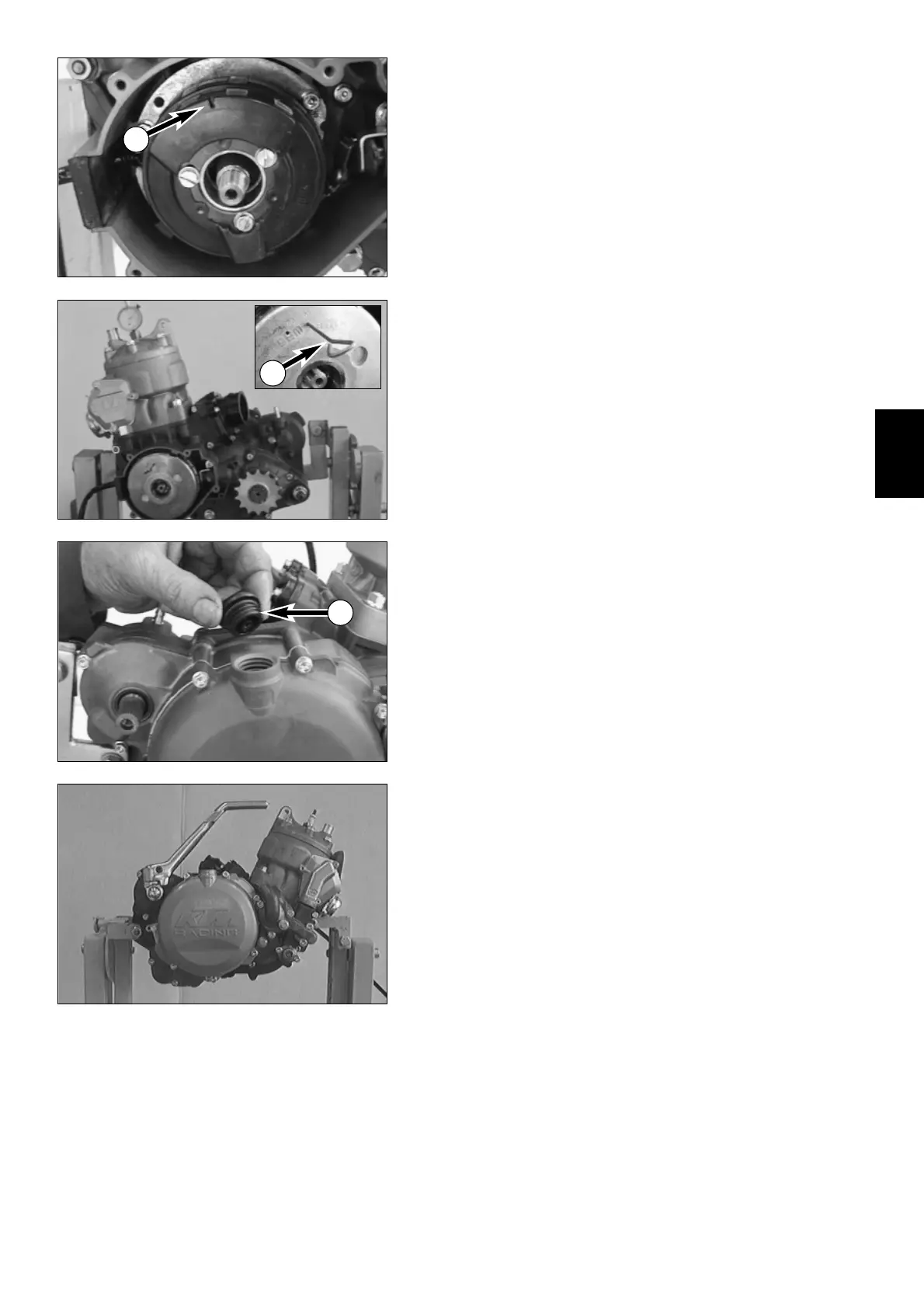

5.20 Filling in gear oil

– Mount oil drain screw with new gasket and tighten.

– Fill in 0.8 liters SAE 30 engine oil and check that engine does not leak.

– Mount plug

1

.

5.21 Starting lever, foot shift lever

– Push distance bushing onto kickstarter shaft and mount kickstarter.

– Mount shift lever.

– Operate the kickstarter a few times and check if the engine turns freely.

5

9

C

3

1

Loading...

Loading...