S.4

FUEL

SYSTEM

92.4mm

STROKE

SERIES

WSM, 01093

Fuel tightness of

pump element

I

C112F059

Allowable

150

kgflcm?

limit

14.7

MPa,

2

133

psi

Fuel tightness

of

delivery valve

[Z]

INJECTION

NOZZLE

5

seconds

14.7- 13.7bPa

2133- 19OOtxi

Allowable

150- 140

k

f/Cm2

limit

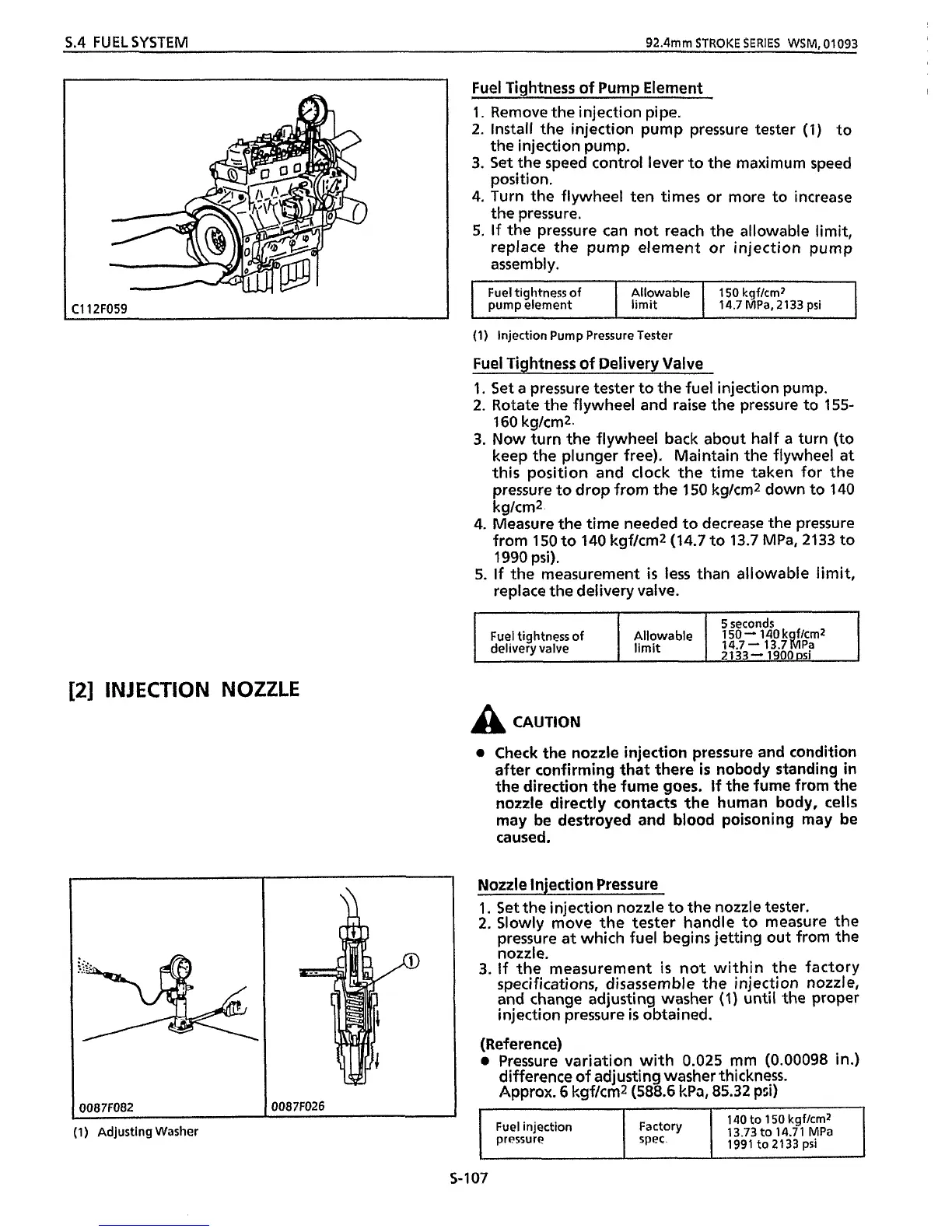

I0087F082

(1)

Adjusting

Washer

0087F026

(1)

Injection Pump Pressure Tester

Fuel Tiahtness of Deliverv Valve

1.

Set

a

pressure tester to

the

fuel injection pump.

2.

Rotate

the

flywheel and raise the pressure to

155-

160 kglcm2.

3.

Now turn the flywheel back about half a turn (to

keep the plunger free).

Maintain

the flywheel

at

this

position and clock

the

time taken for the

pressure to drop from the 150 kglcm2 down to 140

kglcm2

4.

Measure

the

time needed to decrease

the

pressure

from

150

to

140

kgf/cm2

(14.7

to

13.7

MPa,

2133

to

1990 psi).

5.

If

the

measurement

is

less

than

allowable limit,

replace

the

delivery valve.

CAUTION

0

Check

the

nozzle injection pressure and condition

after confirming that there

is

nobody standing in

the

direction

the

fume goes. If

the

fume from the

nozzle directly contacts the human body,

cells

may be destroyed and blood poisoning may be

caused.

Nozzle Injection Pressure

1.

Set

the

injection nozzle to the nozzle tester.

2.

Slowly move the tester handle to measure

the

pressure at which fuel begins jetting out from the

nozzle.

3.

If

the

measurement

is

not within

the

factory

specifications, disassemble

the

injection nozzle,

and change adjusting washer

(1)

until

the

proper

injection pressure

is

obtained.

(Reference)

0

Pressure variation with

0.025

mm

(0.00098

in.)

difference of adjusting washer thickness.

Approx.

6

kgf/cm2

(588.6

kPa,

85.32

psi)

I

140

to

150

kgfkm2

13.73

to

14.71

MPa

1991 to2133

psi

Fuel

injection

pressure

I

S-107

Loading...

Loading...