Page 8

NOTE - Check local codes before connecting the drain

line to an existing drainage system. Insulate the drain

lines where sweating could cause water damage.

TEST CONDENSATE DRAIN

Test the drain pan and drain line after installation:

1 - Pour several quarts of water into drain pan. Use

enough water to ll both the drain trap and the line.

2 - Check the installed drain pan. Drain pan must be

draining completely. Drain line ttings must not be

leaking. Water must be draining from the end of the

primary drain line.

3 - Correct any leaks found.

Duct System and Filters

DUCT SYSTEM

The air handler is provided with anges for the connection

of the supply plenum.

Supply and return duct system must be adequately sized

to meet the system’s air requirements and static pressure

capabilities. The duct system should be insulated with a

minimum of 1" thick insulation with a vapor barrier in con-

ditioned areas or 2" minimum in unconditioned areas.

Supply plenum should be the same size as the anged

opening provided around the blower outlet and should ex-

tend at least 3 ft. from the air handler before turning or

branching off plenum into duct runs. The plenum forms an

extension of the blower housing and minimizes air expan-

sion losses from the blower.

FILTERS

A lter is provided. Table 1 lists the lter size for each unit.

TABLE 1. Unit Air Filter Size Chart

CBA25UH Filter Size – In.

-018, -024, -030 15" x 20" x 1"

-036, -042, -048, -060 18" x 20" x 1"

IMPORTANT

If a high efciency lter is being installed as part of this

system to ensure better indoor air quality, the lter must

be properly sized. High efciency lters have a higher

static pressure drop than standard efciency glass/foam

lters. If the pressure drop is too great, system capacity

and performance may be reduced. The pressure drop

may also cause the limit to trip more frequently during

the winter and the indoor coil to freeze in the summer,

resulting in an increase in the number of service

calls. Before using any lter with this system, check

the specications provided by the lter manufacturer

against the data given in the appropriate Lennox Product

Specications bulletin. Additional information is provided

in Service and Application Note ACC002 (August 2000)..

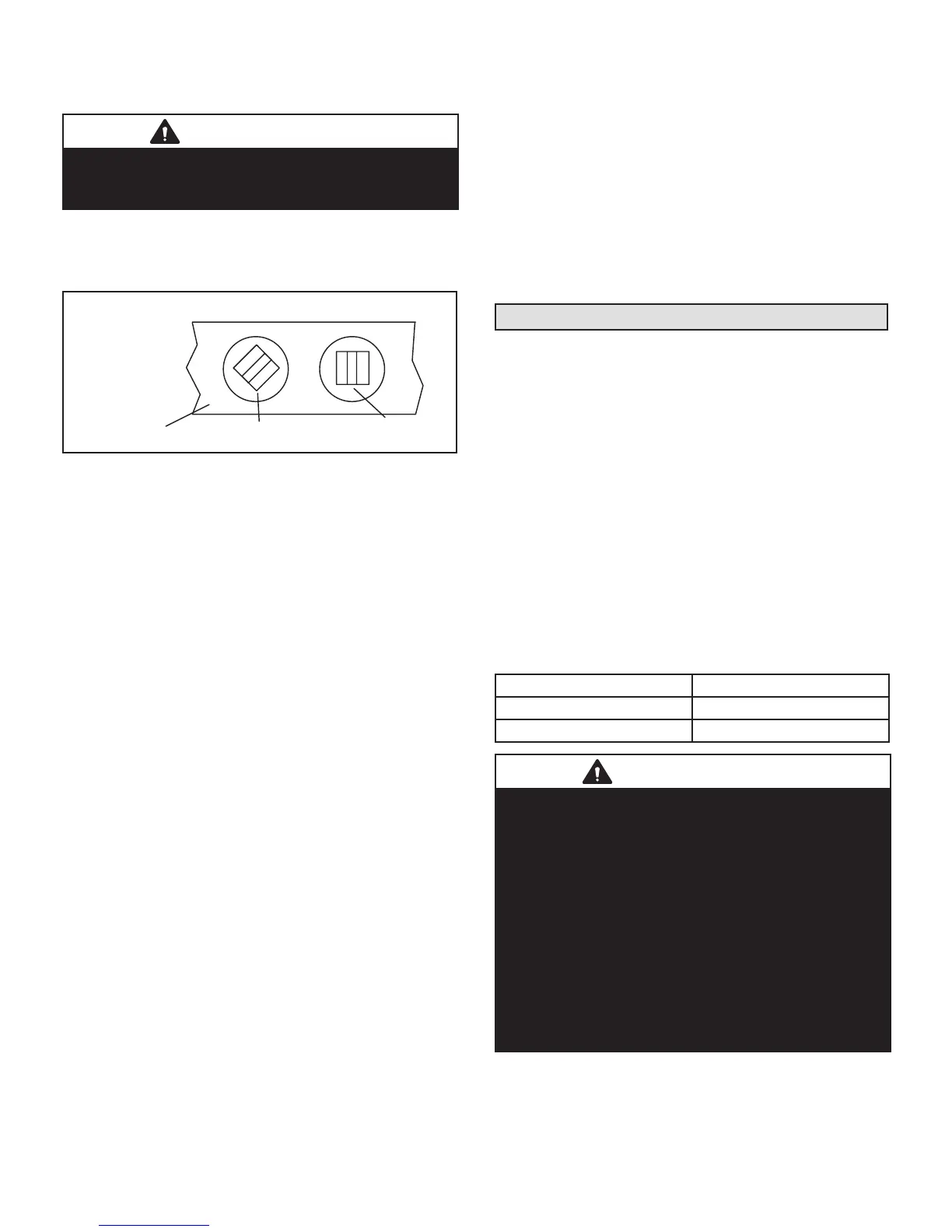

INSTALL CONDENSATE DRAIN

The air handler is provided with 3/4" NPT condensate

drain connections.

IMPORTANT

On some pans, the primary and secondary drain holes

have knockouts.

Conrm primary and secondary drains are open.

1 - CBA25UH units are equipped with a drain pan, which

includes green (main drain) and red (secondary

drain) plugs. Unscrew the plugs to remove them

before inserting condensate drain ttings.

DRAIN PAN

RED SECONDARY

UNSCREW PLUGS

AND CONNECT

PROPERLY SIZED

FIELD-PROVIDED

FITTINGS AND

DRAIN LINES.

GREEN MAIN

FIGURE 8. Drain Line Connections

2 - Install properly sized, eld-provided connection

ttings and connect primary drain line to the main

drain pan connection.

NOTE - When installing drain line connection ttings to

the drain pan, hand tighten the tting and use a thread

sealant. Over-tightening the ttings can split connections

on the drain pan.

3 - If the secondary drain line is to be used, remove the

plug or the knockout and route the drain line so that

water draining from the outlet will be easily noticed

by the homeowner. Refer to local codes for drain

trap requirements on the secondary drain line.

4 - Check again to ensure drain ports and drain pan

are free of all debris.

5 - Plug and check any unused drain pan openings for

tightness. Torque plugs to 30 in. lb. to prevent water

leaks or seepage from the drain pan.

6 - Install a 2" trap in the main (primary) drain lines as

close to the unit as practical (see gure 6). Make

sure the top of the trap is below the connection to

the drain pan to allow complete drainage of the pan.

NOTE - Horizontal runs must have an anti-siphon air vent

(standpipe) installed ahead of the horizontal run. See g-

ure 6. An extremely long horizontal run may require an

oversized drain line to eliminate air traps.

NOTE - Do not operate air handler without a trap in the

main (primary) drain. The condensate drain is on the

negative pressure side of the blower; therefore, air being

pulled through the condensate line will not allow positive

drainage without a proper trap.

7 - Route the drain line to the outside or to an

appropriate drain. Drain lines must be installed so

they do not block service access to the front of the

air handler. A 24" clearance is required for lter, coil,

or blower removal and service access.

Loading...

Loading...