Page 4

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take

care while handling this equipment and wear gloves and

protective clothing.

General Information

The Elite

®

CBA27UHE series air handler with all-alumi-

num coil is designed for installation with optional eld-in-

stalled electric heat and a matching HFC-410A outdoor

unit.

This instruction is intended as a general guide and does

not supersede local or national codes in any way. Consult

authorities having jurisdiction before installation.

Shipping and Packing List

Package 1 of 1 contains:

1 – Assembled air handler unit

1 – Horizontal drip shield (CBA27UHE-060 only)

1 – Pipe nipple (Sch80, 3/4" I.D. x 5"

1 – Warranty card

NOTE – For downow applications, order kit number

83M57.

Check the air handler for shipping damage; if found, im-

mediately contact the last carrier.

Requirements

IMPORTANT

This unit must be matched with an indoor coil as specied

in the Lennox Engineering Handbook. Coils previously

charged with HCFC-22 must be ushed.

In addition to conforming to manufacturer’s installation in-

structions and local municipal building codes, installation

of Lennox air handler units (with or without optional elec-

tric heat), shall conform with the following National Fire

Protection Association (NFPA) standards:

• NFPA No. 90A - Standard for Installation of Air Condi-

tioning and Ventilation Systems

• NFPA No. 90B - Standard for Installation of Residence

Type Warm Air Heating and Air Conditioning Systems

This unit is approved for installation clearance to combus-

tible material as stated on the unit rating plate. Accessi-

bility and service clearances must take precedence over

combustible material clearances.

Installing the Unit

These units are factory-congured for upow and hori-

zontal right-hand discharge installation. For downow or

horizontal left-hand discharge, certain eld modications

are required.

DISASSEMBLE/REASSEMBLE AIR HANDLER UNITS

The air handler units consists of two factory-assembled

sections. It may be necessary to disassemble the sections

when positioning the unit for installation.

To disassemble:

1 - Remove access panels.

2 - Remove both blower and coil assemblies. This will

lighten the cabinet for lifting.

3 - Remove one screw from the left and right posts

inside the unit. Remove one screw from each

side on the back of the unit. Unit sections will now

separate.

To reassemble:

1 - Align cabinet sections together.

2 - Reinstall screws.

3 - Replace blower and coil assemblies.

4 - Replace access panel.

UPFLOW APPLICATION

Use the following procedures to congure the unit for up-

ow operations:

1 - Remove access panels.

2 - Remove and discard the horizontal drip shield (-060

model, used only on horizontal applications) and

the corrugated padding between the blower and coil

assembly.

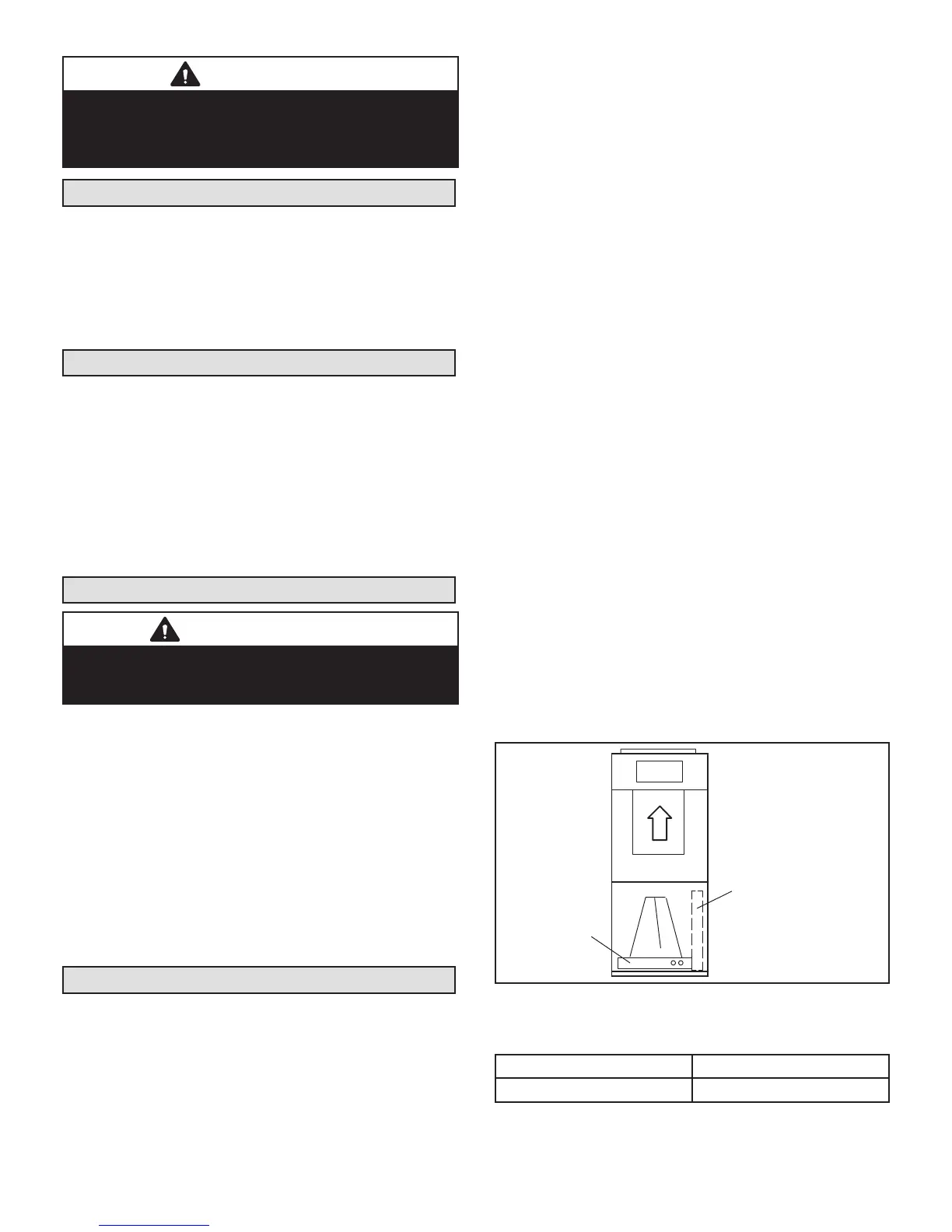

3 - The horizontal drain pan must be removed when

the coil blower is installed in the upow position.

Removing the horizontal drain pain will allow proper

air ow and increased efciency.

4 - After removing the horizontal drain pan, place the

unit in the desired location. Set unit so that it is level.

Connect return and supply air plenums as required

using sheet metal screws as illustrated in gure 1.

5 - Install units that have no return air plenum on a

stand that is at least 14" from the oor to allow for

proper air return. Lennox offers an optional upow

unit stand as listed in table 1.

HORIZONTAL DRAIN PAN

(MUST BE REMOVED)

UP-FLOW /

DOWN-FLOW

DRAIN PAN

FIGURE 1. Upow Conguration

TABLE 1. Optional Side-Return Unit Stand

(Upow Only)

Model Kit Number

All unit sizes 45K32

Loading...

Loading...