Page 13

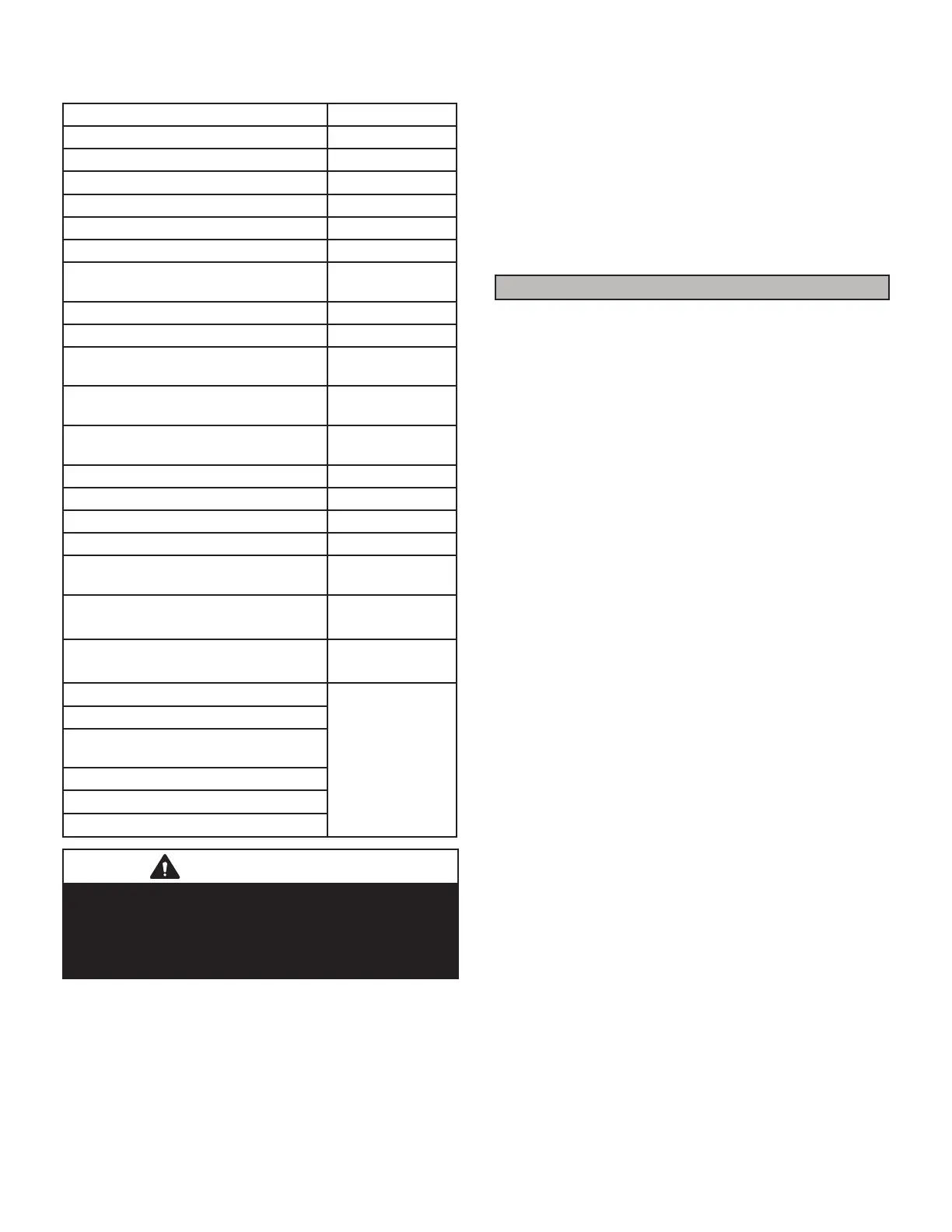

TABLE 4

PIPING AND FITTINGS SPECIFICATIONS

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

Schedule 40 CPVC (Pipe) F441

Schedule 40 CPVC (Fittings) F438

SDR-21 PVC or SDR-26 PVC (Pipe) D2241

SDR-21 CPVC or SDR-26 CPVC (Pipe) F442

Schedule 40 ABS Cellular Core DWV

(Pipe)

F628

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS-DWV (Drain Waste & Vent) (Pipe &

Fittings)

D2661

PVC-DWV (Drain Waste & Vent) Pipe &

Fittings)

D2665

PRIMER & SOLVENT CEMENT

ASTM

SPECIFICATION

PVC & CPVC Primer F656

PVC Solvent Cement D2564

CPVC Solvent Cement F493

ABS Solvent Cement D2235

PVC/CPVC/ABS All Purpose Cement

For Fittings & Pipe of the same material

D2564, D2235,

F493

ABS to PVC or CPVC Transition Solvent

Cement

D3188

CANADA PIPE & FITTING & SOLVENT

CEMENT

MARKING

PVC & CPVC Pipe and Fittings

ULCS636

PVC & CPVC Solvent Cement

ABS to PVC or CPVC Transition

Cement

POLYPROPYLENE VENTING SYSTEM

PolyPro

®

by Duravent

InnoFlue

®

by Centrotherm

IMPORTANT

EL296DFE exhaust and intake connections are made

of PVC. Use PVC primer and solvent cement when

using PVC vent pipe. When using ABS vent pipe, use

transitional solvent cement to make connections to the

PVC ttings in the unit.

Use PVC primer and solvent cement or ABS solvent ce-

ment meeting ASTM specications, refer to TABLE 4.

As an alternate, use all purpose cement, to bond ABS,

PVC, or CPVC pipe when using ttings and pipe made of

the same materials. Use transition solvent cement when

bonding ABS to either PVC or CPVC.

Low temperature solvent cement is recommended during

cooler weather. Metal or plastic strapping may be used for

vent pipe hangers. Uniformly apply a liberal coat of PVC

primer for PVC or use a clean dry cloth for ABS to clean

inside socket surface of tting and male end of pipe to

depth of tting socket

Canadian Applications Only - Pipe, ttings, primer and

solvent cement used to vent (exhaust) this appliance must

be certied to ULC S636 and supplied by a single manu-

facturer as part of an approved vent (exhaust) system. In

addition, the rst three feet of vent pipe from the furnace

ue collar must be accessible for inspection.

Venting Options

The EL296DFE is shipped with vent exhaust / air intake

connection at the top cap. See FIGURE 20. Using parts

provided, the furnace may be eld modied to have these

connections on the right side of the furnace cabinet. See

FIGURE 23 and follow the steps below. For left side vent-

ing order kit 87W73.

1 - Remove inner blower door.

2 - Loosen hose clamps which attach rubber ttings to

the white PVC pipes inside the vestibule area. See

FIGURE 20.

3 - Loosen the clamp which secures the pipes at the

blower deck. See gure 20.

4 - Remove white PVC pipes, slide up and out thru the

top cap.

5 - Remove the black plastic tting in top cap which

previously aligned the PVC pipes.

6 - Remove the remaining parts of the pipe clamp at the

blower deck.

7 - Remove the sheet metal patch plate on the side

of the cabinet which covers the openings for side

venting option. Save screws for reuse.

8 - Re-use the patch plate to cover the hole in the top

cap. See FIGURE 21. Remove the 2 screws which

secure the top cap to the furnace on the right side

and re-install securing the right edge of the patch

plate and the right side of the top cap to the furnace.

Use 2 self-drilling sheet metal screws (provided) to

nish securing the left edge of the patch plate on the

left side.

9 - Use a utility knife to cut out the cabinet insulation

for the right side vent / air intake. 10 -Install the two

90° street elbows (provided) through the side of the

cabinet. The male side of each elbow should extend

down through the blower deck and connect to the

rubber ttings below. Once the elbows are properly

positioned, tighten each clamp.

10 - Install the two 90° street elbows (provided) through

the side of the cabinet. The male side of each

elbow should extend down through the blower deck

and connect to the rubber ttings below. Once the

elbows are properly positioned, tighten each clamp.

11 - Peel protective backing from side vent sealing

gaskets (2) and apply to side vent sealing plates (2)

as shown in FIGURE 23.

Loading...

Loading...