Page 12

506101−01 07/09

REQUIRED EQUIPMENT

Equipment required to flush the existing line set and indoor

unit coil:

S Two clean HCFC−22 recovery bottles,

S Oilless recovery machine with pump-down feature,

S Two gauge sets (one for HCFC−22; one for

HFC−410A).

PROCEDURE

1. Connect the following:

S HCFC−22 cylinder with clean refrigerant to the

suction service valve,

S HCFC−22 gauge set to the liquid line valve,

S Recovery machine with an empty recovery tank to

the gauge set.

2. Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the

existing system line set and indoor unit coil.

3. Invert the cylinder of clean HCFC−22 and open its

valve to allow liquid refrigerant to flow into the system

through the suction line valve. Allow the refrigerant to

pass from the cylinder and through the line set and the

indoor unit coil before it enters the recovery machine.

4. After all of the liquid refrigerant has been recovered,

switch the recovery machine to suction recovery so

that all of the HCFC−22 suction is recovered. Allow the

recovery machine to pull a vacuum on the system.

5. Close the valve on the inverted HCFC−22 drum and

the gauge set valves. Pump the remaining refrigerant

out of the recovery machine and turn the machine off.

6. Use dry nitrogen to break the vacuum on the

refrigerant lines and indoor unit coil before removing

the recovery machine, gauges and refrigerant drum.

Installing New Indoor Unit Metering

Device

XC16 units can be configured for use in with HFC−410A

fixed orifice or TXV metering devices. This section

provides instructions on installing either a fixed orifice or

TXV refrigerant metering device.

1

2

3

4

5

6

7

8

9

10

11

12

1/8 TURN

1

2

3

4

5

6

7

8

9

10

11

12

1/2 TURN

Figure 22. Tightening Distance

XC16 ENGINEERING HANDBOOK

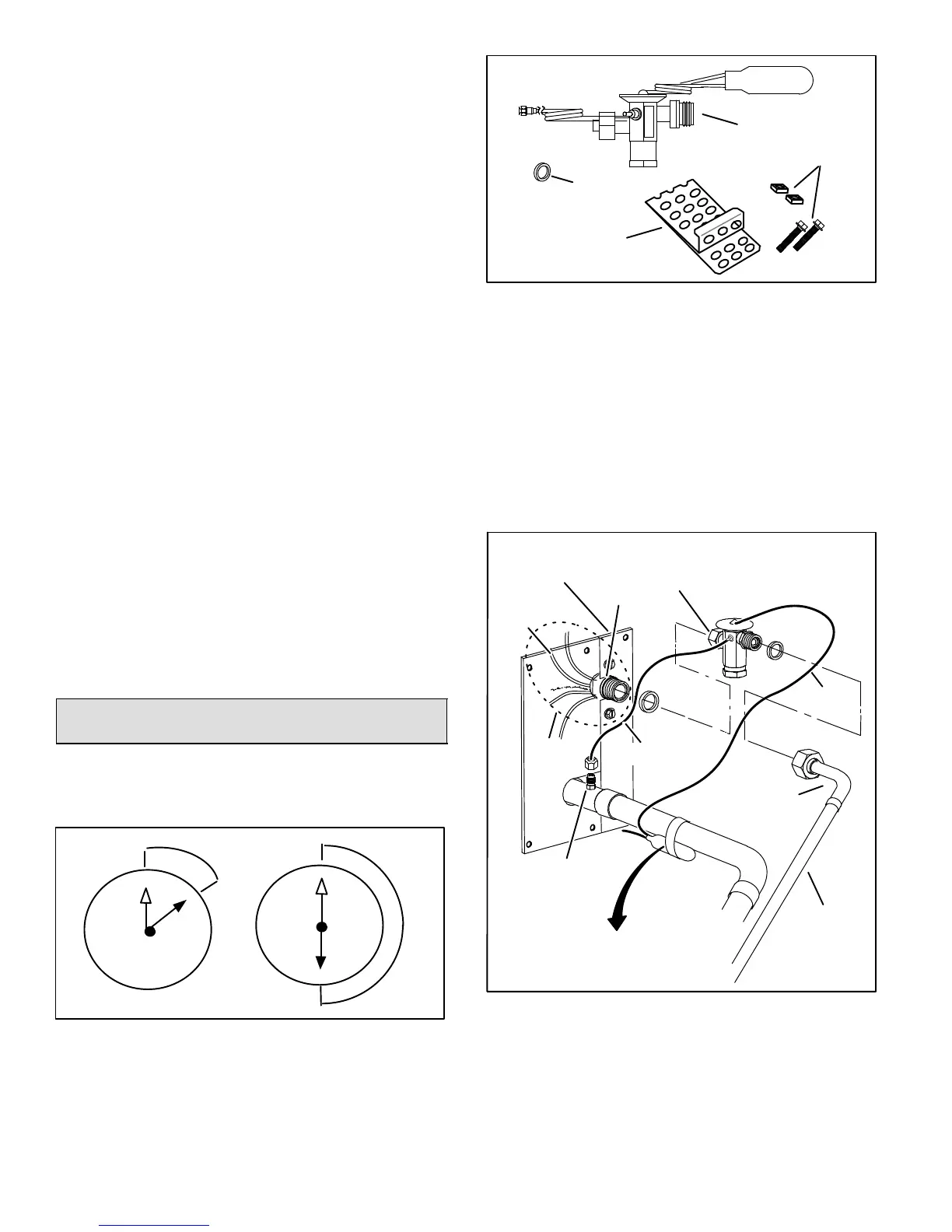

See the XC16 Engineering Handbook for approved

indoor/outdoor match−ups, applicable TXV kit and

application information. The following is the typical

contents of a TXV kit:

TXV (1)

COPPER

MOUNTING

STRAP (1)

HEX HEAD BOLTS

AND NUTS (2)

TEFLON

RINGS (2)

Figure 23. TXV Kit Components

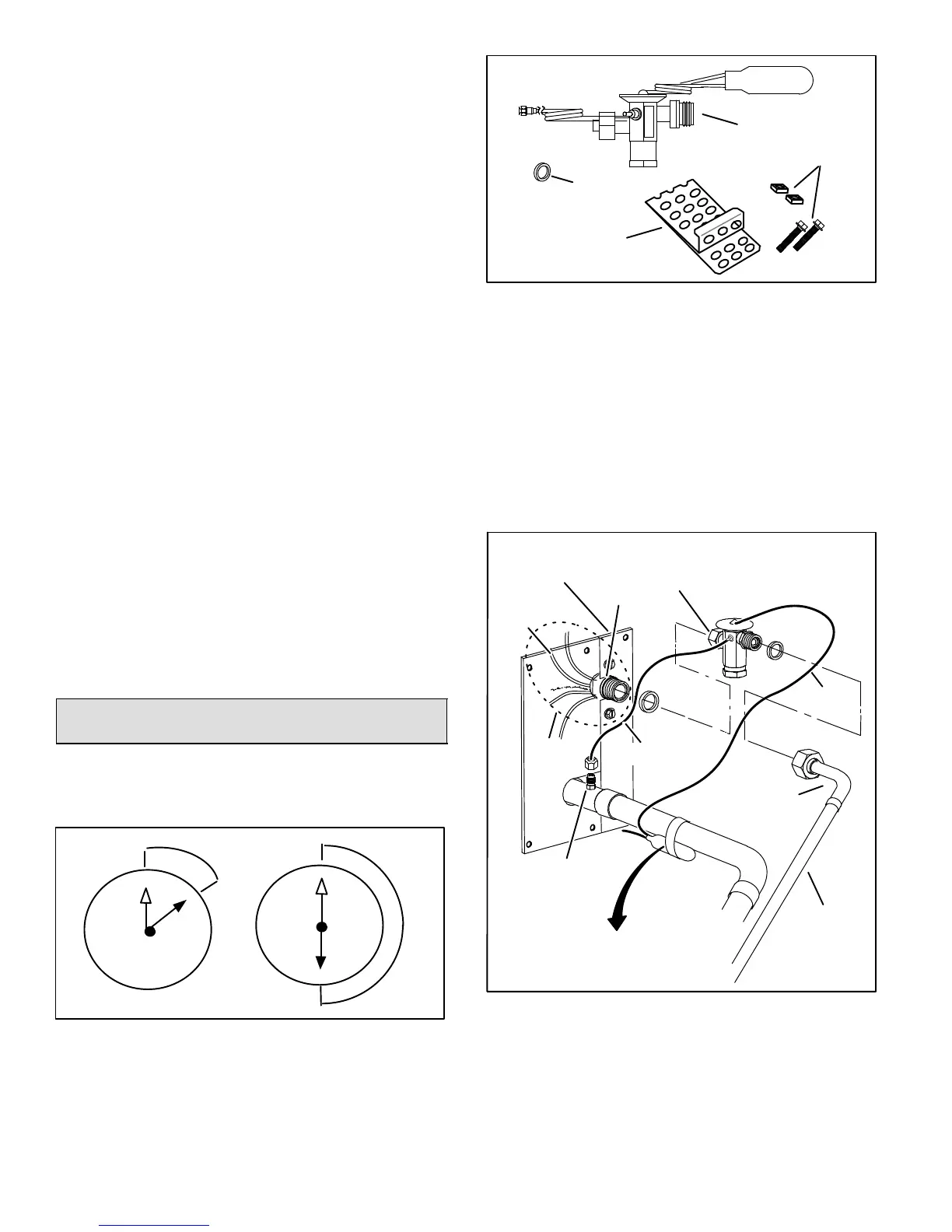

TYPICAL TXV INSTALLATION PROCEDURE

The TXV unit can be installed internal or external to the

indoor coil. In applications where an uncased coil is being

installed in a field−provided plenum, install the TXV in a

manner that will provide access for field servicing of the

TXV. Refer to Figure 24 for reference during installation of

TXV unit.

To prevent any possibility of water damage, properly

insulate all parts of the TXV assembly that may sweat due

to temperature differences between the valve and its

surrounding ambient temperatures.

TWO PIECE

PATCH PLATE

(UNCASED COIL

ONLY)

SUCTION

LINE

LIQUID LINE

ORIFICE

HOUSING

DISTRIBUTOR

TUBES

LIQUID

LINE

MALE EQUALIZER LINE

FITTING (SEE FIGURE 26

FOR FURTHER DETAILS)

SENSING

LINE

EQUALIZER

LINE

TXV

TEFLON

RING

(Uncased Coil Shown)

SENSING BULB INSULATION IS

REQUIRED IF MOUNTED EXTERNAL

TO THE COIL CASING. SEE FIGURE 25

FOR BULB POSITIONING.

STUB END

TEFLON

RING

LIQUID LINE ASSEMBLY

WITH BRASS NUT

DISTRIBUTOR

ASSEMBLY

Figure 24. Typical TXV Installation

1. Remove the field−provided fitting that temporary

reconnected the liquid line to the indoor unit’s

distributor assembly.

2. Install one of the provided Teflon rings around the

stubbed end of the TXV and lightly lubricate the

connector threads and expose surface of the Teflon

ring with refrigerant oil.

Loading...

Loading...