Page 13

XC16 SERIES

3. Attach the stubbed end of the TXV to the liquid line

orifice housing. Finger tighten and use an appropriately

sized wrench to turn an additional 1/2 turn clockwise

as illustrated in figure 22, or 20 ft−lb.

4. Place the remaining Teflon ring around the other end

of the TXV. Lightly lubricate connector threads and

expose surface of the Teflon ring with refrigerant oil.

5. Attach the liquid line assembly to the TXV. Finger

tighten and use an appropriately sized wrench to turn

an additional 1/2 turn clockwise as illustrated in figure

22, or 20 ft−lb.

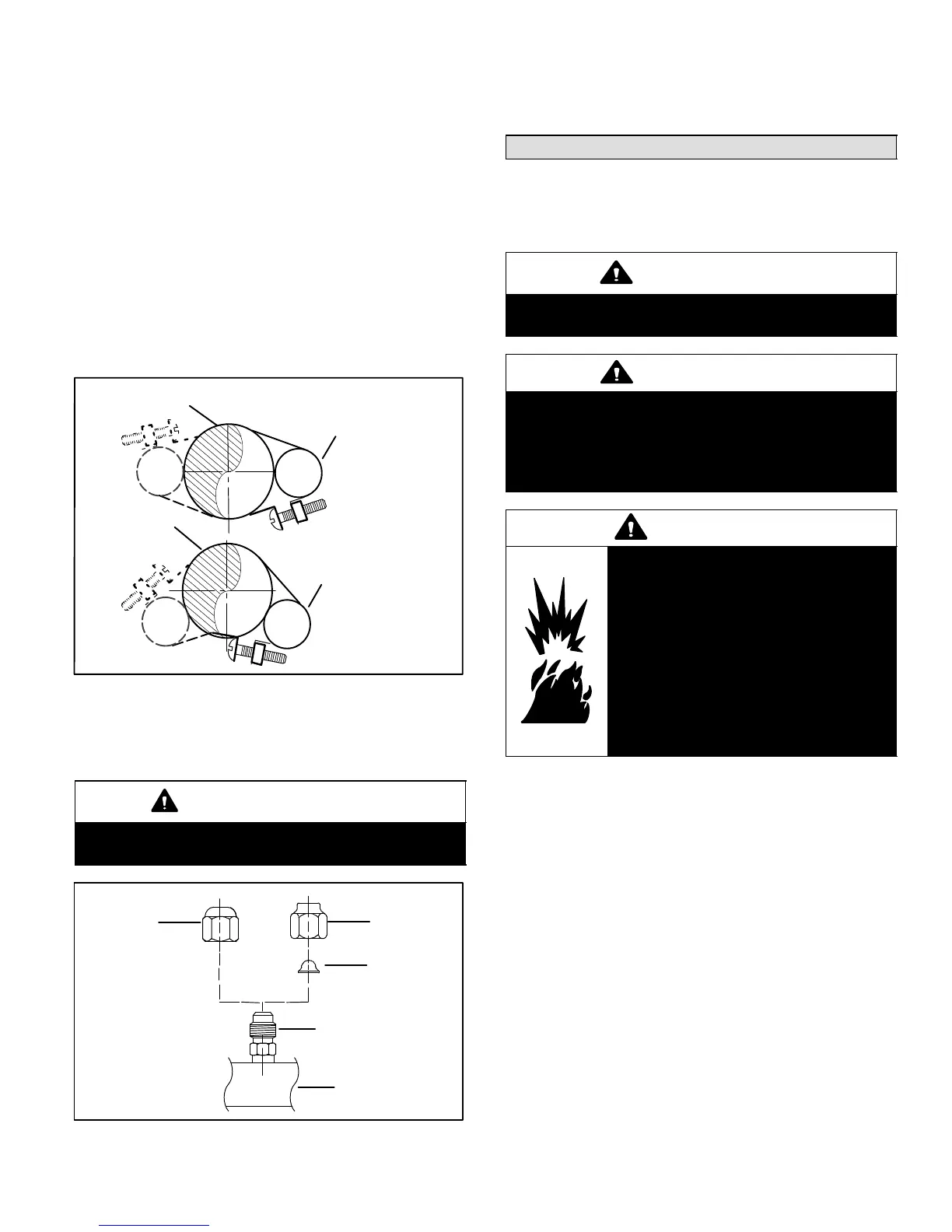

6. Attach the suction line sensing bulb in the proper

orientation as illustrated in figure 25 using the clamp

and screws provided.

NOTE − Insulating the sensing bulb once installed may be

required when the bulb location is external to the coil

casing.

ON 7/8" AND LARGER LINES,

MOUNT SENSING BULB AT

EITHER THE 4 OR 8 O’CLOCK

POSITION. NEVER MOUNT

ON BOTTOM OF LINE.

12

ON LINES SMALLER THAN

7/8", MOUNT SENSING BULB

AT EITHER THE 3 OR 9

O’CLOCK POSITION.

12

BULB

SUCTION LINE

SUCTION LINE

NOTE − NEVER MOUNT ON

BOTTOM OF LINE.

BULB

BULB

BULB

Figure 25. TXV Sensing Bulb Installation

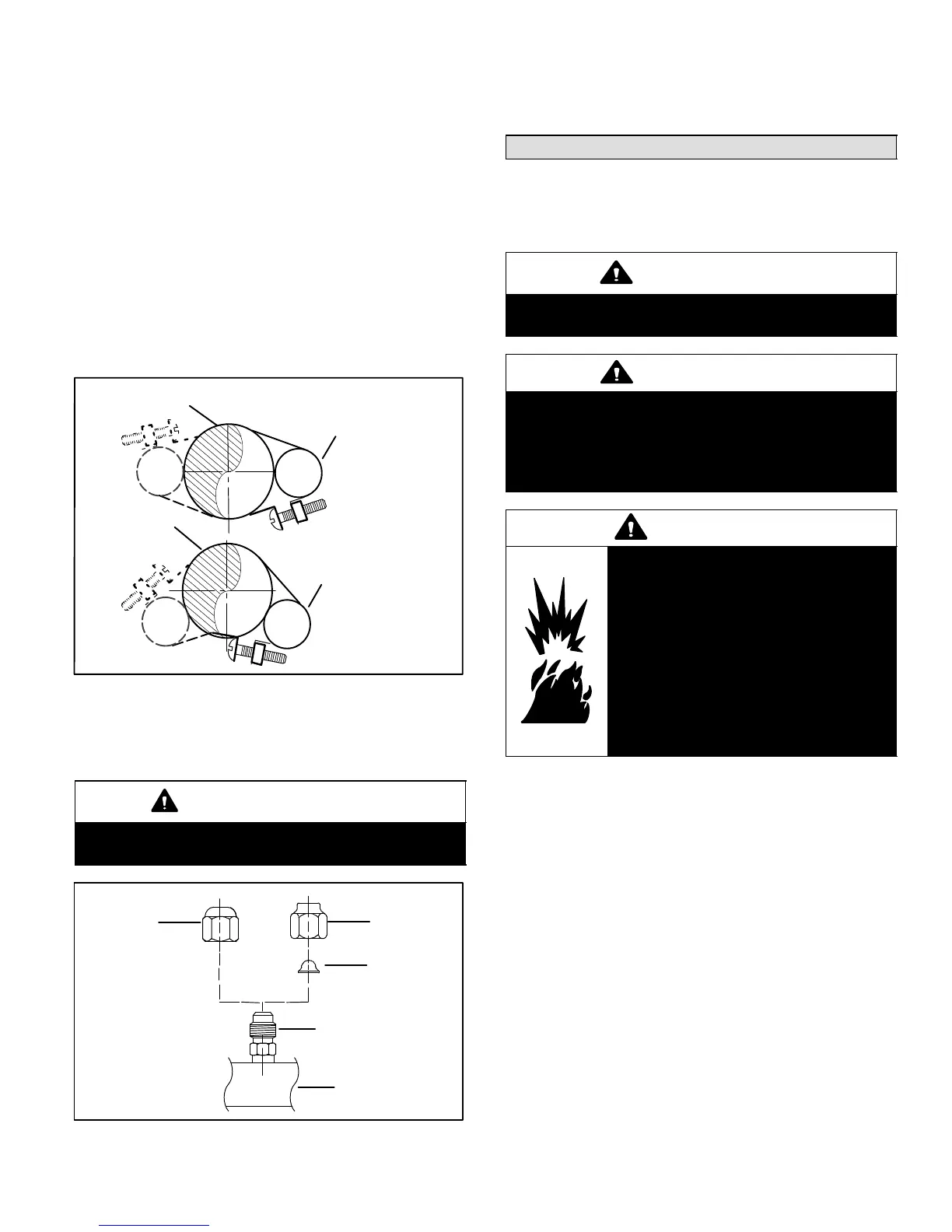

7. Remove and discard either the flare seal cap or flare

nut with copper flare seal bonnet from the equalizer

line port on the suction line as illustrated in figure 26.

IMPORTANT

When removing the flare nut, ensure that the copper

flare seal bonnet is removed.

SUCTION LINE

FLARE NUT

COPPER

FLARE SEAL

BONNET

MALE BRASS EQUALIZER

LINE FITTING

FLARE SEAL

CAP

OR

Figure 26. Copper Flare Seal Bonnet Removal

8. Connect the equalizer line from the TXV to the

equalizer suction port on the suction line. Finger

tighten the flare nut plus 1/8 turn (7 ft−lbs) as illustrated

in figure 22.

Testing for Leaks

After the line set has been connected to both the indoor

and outdoor units, check the line set connections and

indoor unit for leaks. Use the following procedure to test for

leaks:

IMPORTANT

Leak detector must be capable of sensing HFC

refrigerant.

WARNING

Refrigerant can be harmful if it is inhaled.

Refrigerant must be used and recovered

responsibly.

Failure to follow this warning may result in personal

injury or death.

WARNING

Fire, Explosion and Personal Safety

Hazard.

Failure to follow this warning could

result in damage, personal injury or

death.

Never use oxygen to pressurize or

purge refrigeration lines. Oxygen,

when exposed to a spark or open

flame, can cause damage by fire and/

or an explosion, that could result in

personal injury or death.

1. Connect an HFC−410A manifold gauge set high

pressure hose to the suction valve service port.

NOTE − Normally, the high pressure hose is connected to

the liquid line port; however, connecting it to the suction

port better protects the manifold gauge set from high

pressure damage.

2. With both manifold valves closed, connect the cylinder

of HFC−410A refrigerant to the center port of the

manifold gauge set. Open the valve on the HFC−410A

cylinder (suction only).

3. Open the high pressure side of the manifold to allow

HFC−410A into the line set and indoor unit. Weigh in

a trace amount of HFC−410A. [A trace amount is a

maximum of two ounces (57 g) refrigerant or three

pounds (31 kPa) pressure]. Close the valve on the

HFC−410A cylinder and the valve on the high pressure

side of the manifold gauge set. Disconnect the

HFC−410A cylinder.

4. Connect a cylinder of dry nitrogen with a pressure

regulating valve to the center port of the manifold

gauge set.

Loading...

Loading...