Page 15

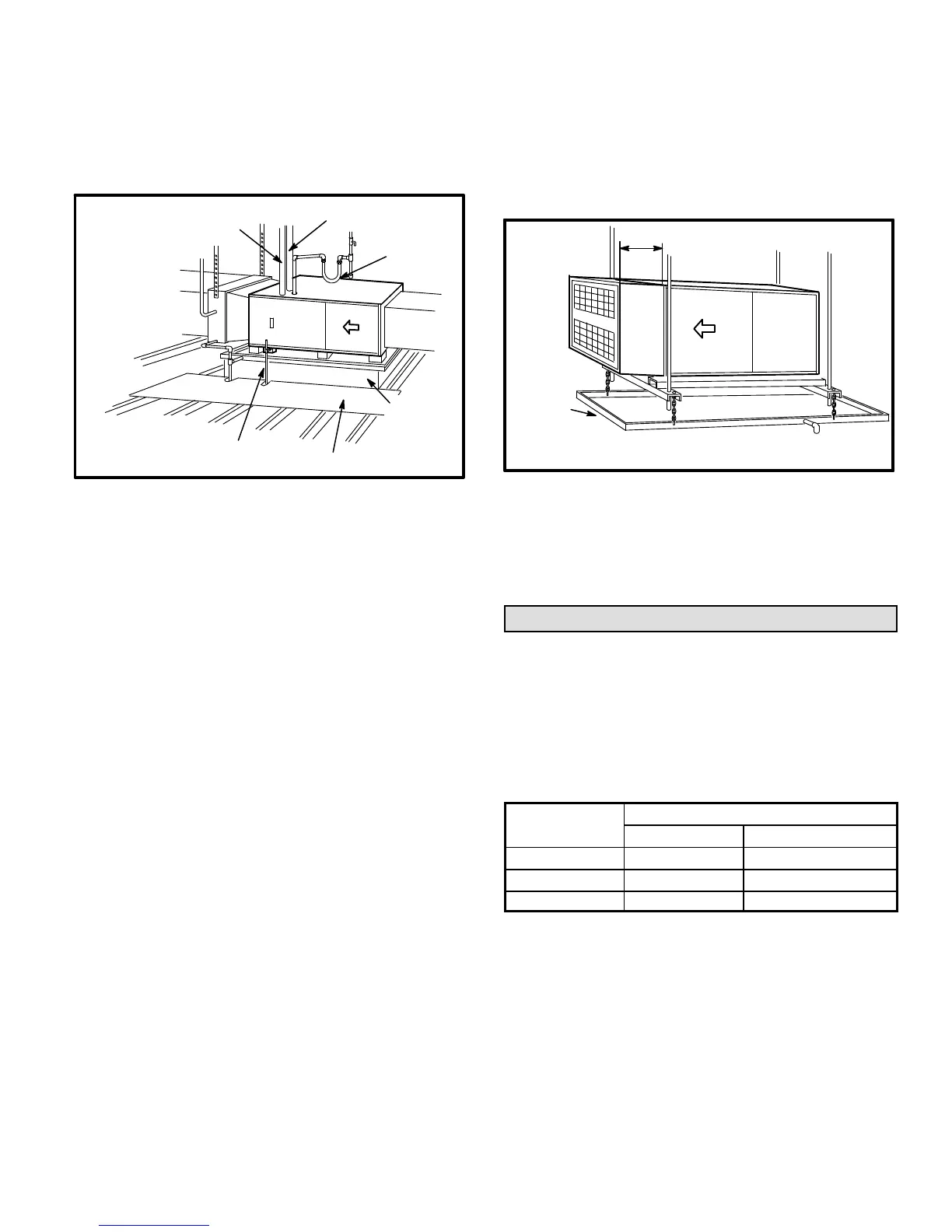

4 − Set unit in drain pan as shown in figure 19. Leave 5−1/2

inches for service clearance below unit for condensate

trap.

5 − Continue with exhaust, condensate and intake piping

installation according to instructions.

INTAKE PIPE

*GAS

CONNECTOR

SERVICE PLATFORM

RAISED

PLATFORM

CONDENSATE LINE

*Gas connector may be

used for Canadian

installation if accept-

able by local authority

having jurisdiction.

EXHAUST PIPE

FIGURE 19

G61MPV Installed in Unit Heater Applications

The G61MPV may also be installed as a unit heater. Either

suspend the furnace from roof rafters or floor joists, as

shown in figure 18, or install the furnace on a field−fabri-

cated raised platform, as shown in figure 19. The unit must

be supported at both ends and beneath the blower deck to

prevent sagging. The condensate trap must be installed

where it can be serviced at a later date.

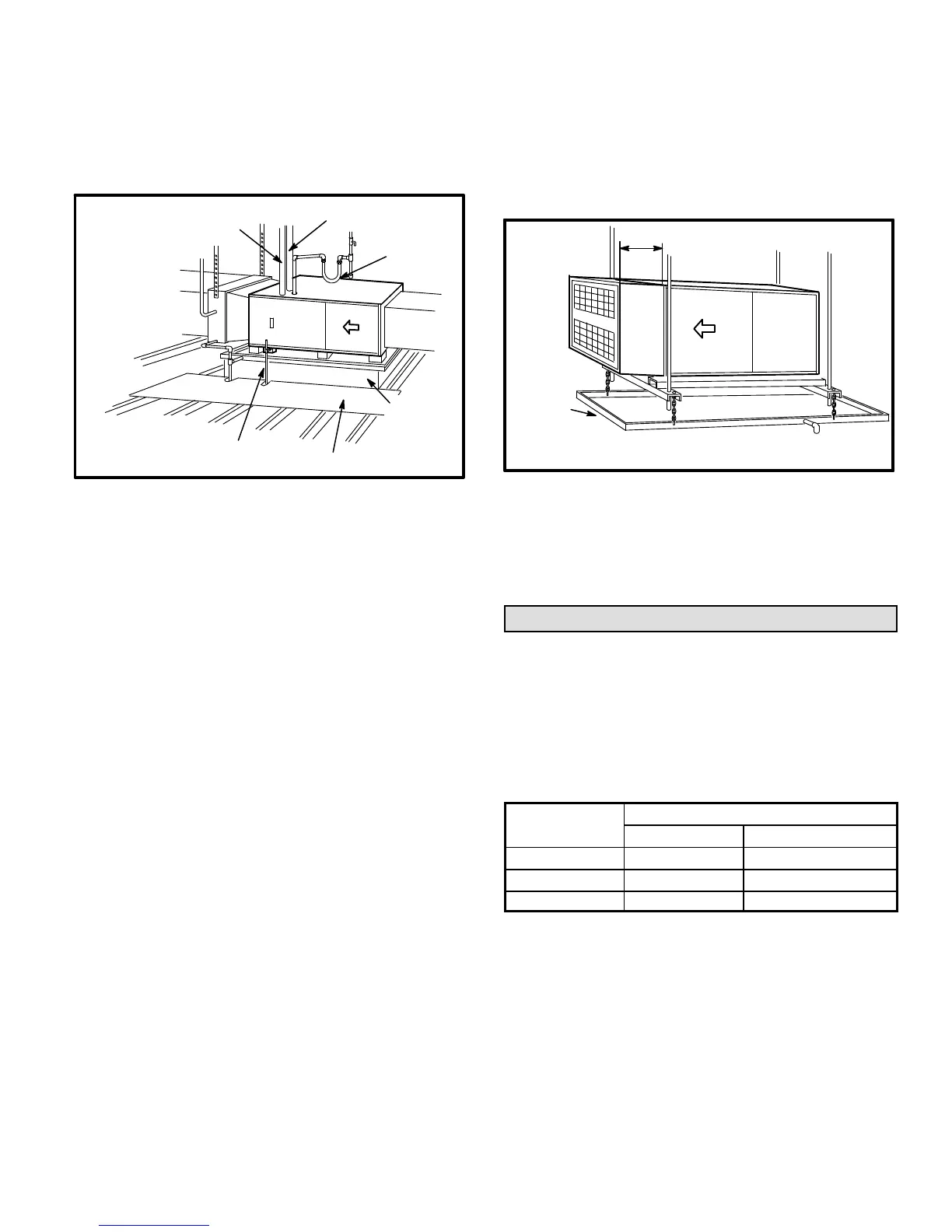

Unit Heater Discharge Duct Guidelines

A field−fabricated and installed discharge air duct and grille

cabinet is suitable for use with the G61MPV heater. Keep

the following items in mind when constructing the cabinet.

1 − Outer dimensions of cabinet should match those of the

unit heater, so the duct/grille cabinet installs flush with

the unit heater cabinet. See figure 20.

2 − Flange both ends of duct/grille cabinet so that screws

can be used to secure cabinet to discharge end of unit

heater.

3 − To ensure proper operation, the duct/grille cabinet

must be at least 18 inches long.

4 − Use #10−16 x 1/2 inch sheet metal screws to secure

duct/grille cabinet to unit, taking care not to damage in-

ternal components of unit heater when drilling holes or

installing screws. See figure 20.

5 − Use adjustable, double−deflection grille(s) to distribute

discharge air. Adjust static pressure to be in the 0.06

inch to 0.10 inch w.c. range.

FIGURE 20

18 in.

MIN.

NOTE − When installing duct/grille cabinet, take care not to damage internal unit

heater components when drilling holes or installing screws.

DRAIN PAN

(to protect

finished

space)

Return Air −− Horizontal Applications

Return air may be brought in only through the end of a fur-

nace installed in the horizontal position. The furnace is

equipped with a removable bottom panel to facilitate

installation. See figure 10.

Filters

This unit is not equipped with a filter or rack. A field−pro-

vided filter is required for the unit to operate properly. Table

3 lists recommended filter sizes.

A filter must be in place whenever the unit is operating.

NOTE − In upflow applications where side return air fil-

ter is installed on same side as the condensate trap, fil-

ter rack must be installed beyond condensate trap to

avoid interference.

TABLE 3

Furnace

Cabinet Width

Filter Size

Side Return Bottom Return

17−1/2" 16 X 25 X 1 (1) 16 X 25 X 1 (1)

21" 16 X 25 X 1 (1) 20 X 25 X 1 (1)

24−1/2" 16 X 25 X 1 (2) 24 X 25 X 1 (1)

Loading...

Loading...