NOTE - The flue collar on all models is sized to accommo-

date 2" Schedule 40 flue pipe, When vent pipe which is

larger than 2" must be used in an upflow application, a 2"

elbow must be applied at the flue collar in order to properly

transition to the larger diameter flue pipe. This elbow must

be added to the elbow count used to determine acceptable

vent lengths. Assign an equivalent feet value to this elbow.

Contact the Application Department for more information

concerning sizing of vent systems which include multiple

pipe sizes.

Use the following steps to correctly size vent pipe diameter,

Refer to Vent Pipe Size Determination Worksheet on

page 65.

1 - Determine the vent termination and its corresponding

equivalent feet value according to table 5,

2 - Determine the number of 90° elbows required for both

indoor and outdoor (e,g. snow riser) use. Calculate the

corresponding equivalent feet of vent pipe.

3 - Determine the number of 45° elbows required for both

indoor and outdoor use, Calculate the corresponding

equivalent feet of vent pipe,

4 - Determine the length of straight pipe required,

5- Add the total equivalent feet calculated in steps 1

through 4 and compare that length to the maximum

values given in table 7 for the proposed vent pipe di-

ameter. If more than one diameter of pipe is being

used, use the appropriate value from table 7 for the

larger sized pipe, If the total equivalent length required

exceeds the maximum equivalent length listed in the

appropriate table, evaluate the next larger size pipe.

AIMPORTANT

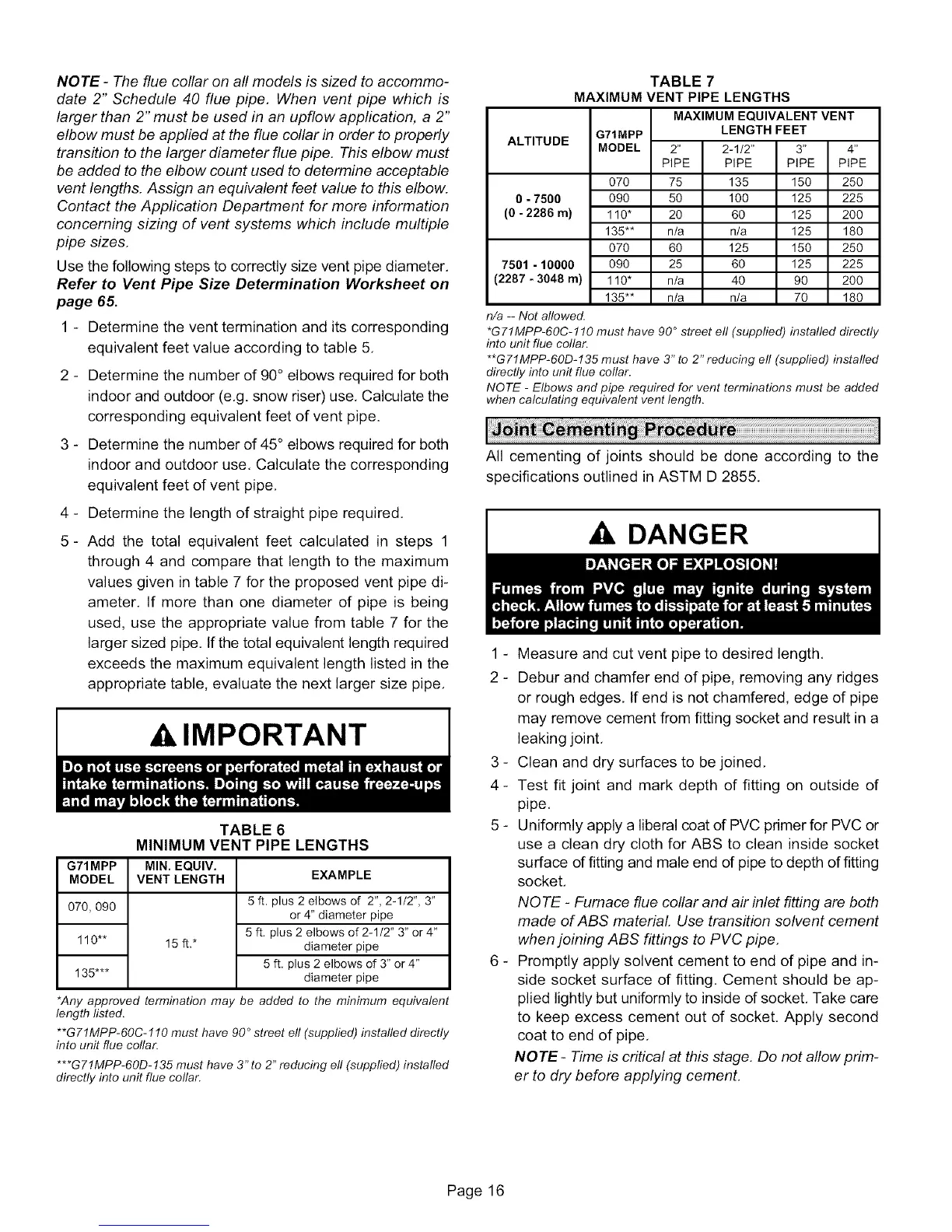

TABLE 6

MINIMUM VENT PIPE LENGTHS

G71MPP

MODEL

070,090

110"*

MIN. EQUIV.

VENT LENGTH

15 ft.*

135"**

*Any approved termination ma

length listed.

EXAMPLE

5 ft. plus 2 elbows of 2", 2-1/2", 3"

or 4" diameter pipe

5 ft. plus 2 elbows of 2-1/2" 3" or 4"

diameter pipe

5 ft, plus 2 elbows of 3" or 4"

diameter pipe

, be added to the minimum equivalent

**G71MPP-60C-110 must have 90 ° street eli (suppfied) installed directly

into unit flue collar.

***G71MPP-60D-135 must have 3" to 2" reducing eli (supplied) installed

directly into unit flue collar.

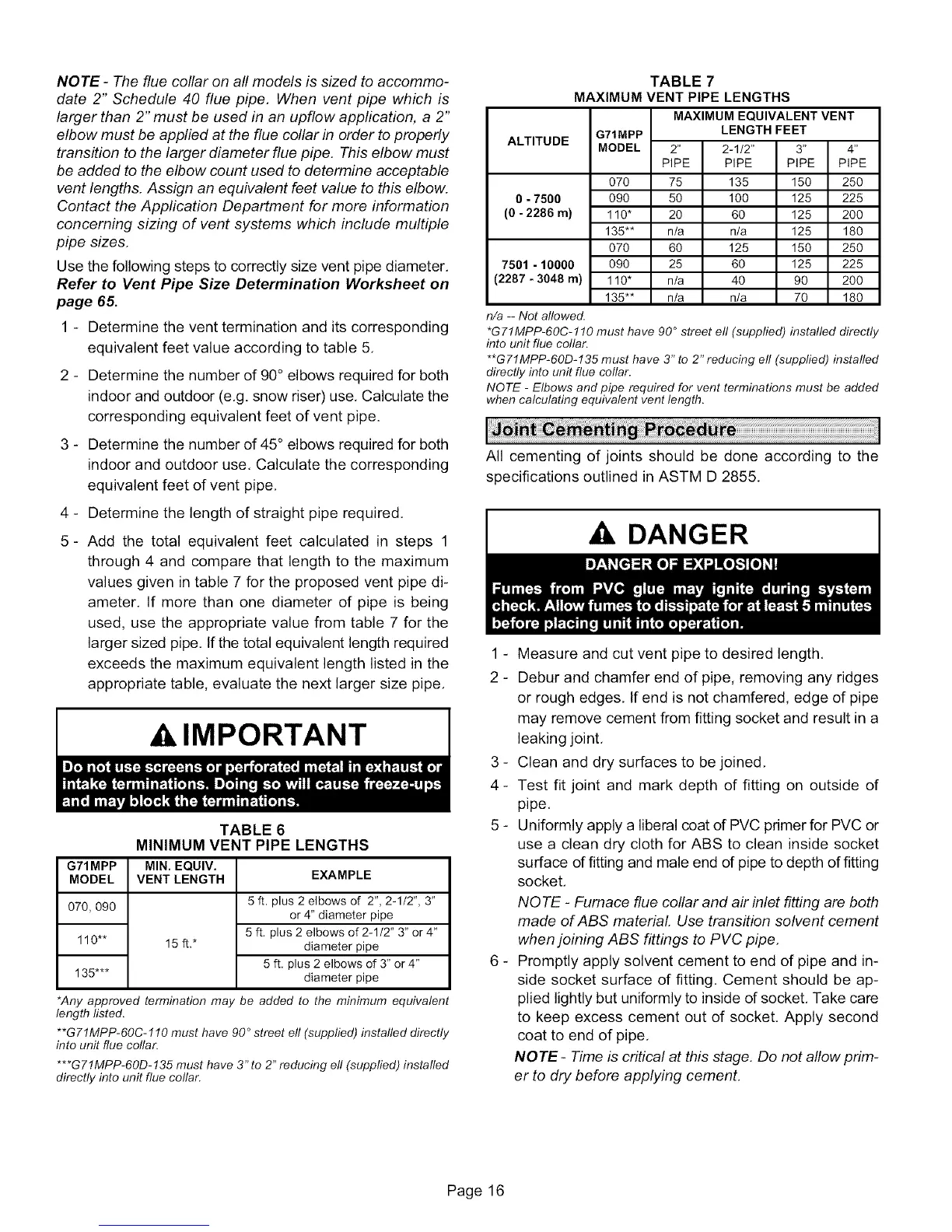

TABLE 7

MAXIMUM VENT PIPE LENGTHS

MAXIMUM EQUIVALENT VENT

G71MPP LENGTH FEET

ALTITUDE

MODEL 2" 2-1/2" 3" 4"

PIPE PIPE PiPE PiPE

070 75 135 150 250

0 - 7500 090 50 100 125 225

(0 - 2286 m) 110" 20 60 125 200

135"* n/a n/a 125 180

070 60 125 150 250

7501 - 10000 090 25 60 125 225

(2287 - 3048 m) 110" n/a 40 90 200

135"* n/a n/a 70 180

n/a -- Not allowed.

*G71MPP-60C-110 must have 90° street eli (supplied) installed directly

into unit flue collar.

**G71MPP-60D-135 must have 3" to 2" reducing eli (supplied) installed

directly into unit flue collar.

NOTE - Elbows and pipe required for vent terminations must be added

when calculating equivalent vent length.

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

,& DANGER

1 - Measure and cut vent pipe to desired length,

2 - Debur and chamfer end of pipe, removing any ridges

or rough edges, If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in a

leaking joint,

3 - Clean and dry surfaces to be joined,

4- Test fit joint and mark depth of fitting on outside of

pipe,

5 - Uniformly apply a liberal coat of PVC primer for PVC or

use a clean dry cloth for ABS to clean inside socket

surface of fitting and male end of pipe to depth of fitting

socket,

NOTE - Furnace flue collar and air inlet fitting are both

made of ABS material. Use transition solvent cement

when joining ABS fittings to PVC pipe,

6 - Promptly apply solvent cement to end of pipe and in-

side socket surface of fitting. Cement should be ap-

plied lightly but uniformly to inside of socket, Take care

to keep excess cement out of socket, Apply second

coat to end of pipe,

NOTE- Time is critical at this stage. Do not allow prim-

er to dry before applying cement.

Page 16

Loading...

Loading...