SettinganUpflowUnit

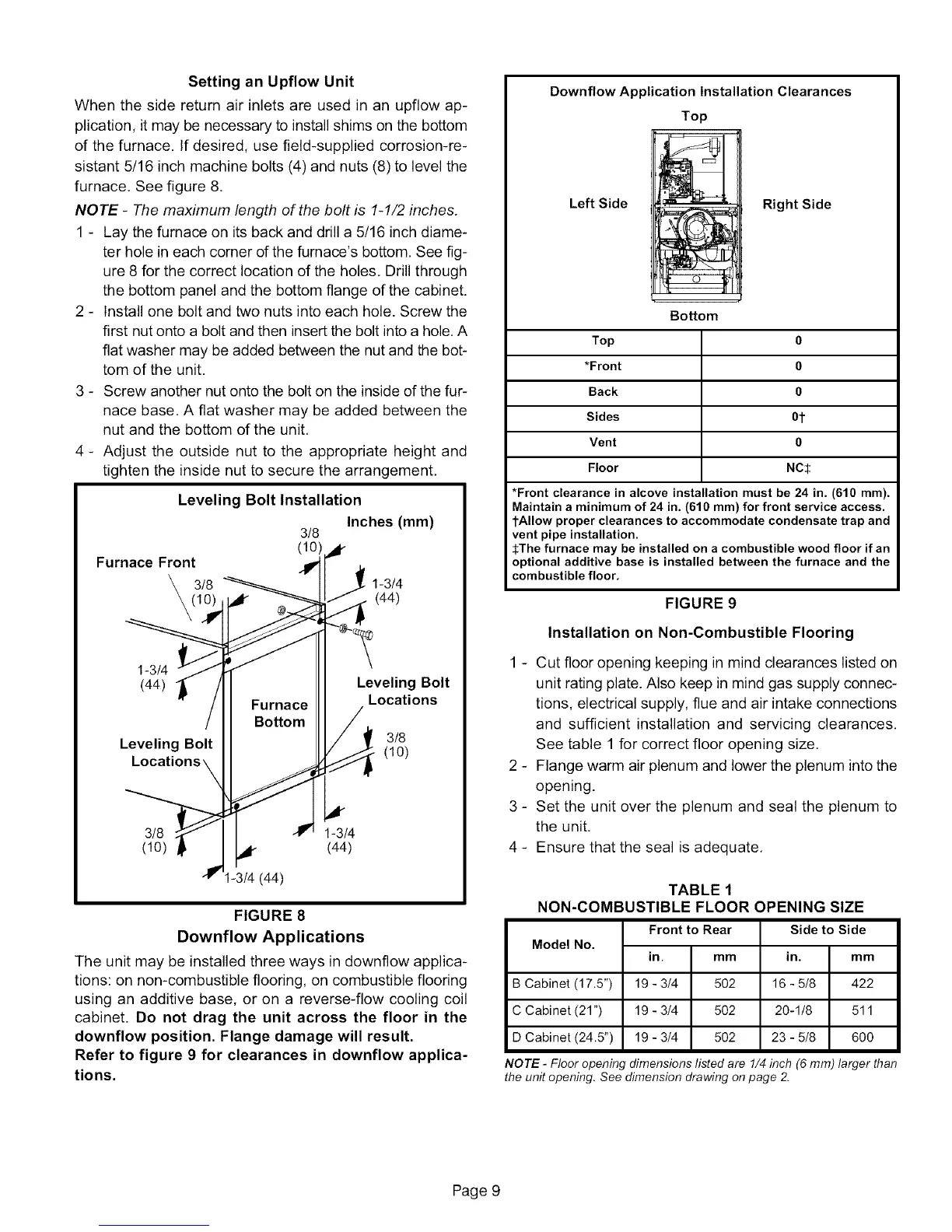

Whenthesidereturnairinletsareusedinanupflowap-

plication,itmaybenecessarytoinstallshimsonthebottom

ofthefurnace.Ifdesired,usefield-suppliedcorrosion-re-

sistant5/16inchmachinebolts(4)andnuts(8)tolevelthe

furnace,Seefigure8,

NOTE - The maximum length of the bolt is 1-1/2 inches.

1 - Lay the furnace on its back and drill a 5/16 inch diame-

ter hole in each corner of the furnace's bottom, See fig-

ure 8 for the correct location of the holes, Drill through

the bottom panel and the bottom flange of the cabinet.

2 - Install one bolt and two nuts into each hole. Screw the

first nut onto a bolt and then insert the bolt into a hole. A

flat washer may be added between the nut and the bot-

tom of the unit.

3 - Screw another nut onto the bolt on the inside of the fur-

nace base. A flat washer may be added between the

nut and the bottom of the unit,

4 - Adjust the outside nut to the appropriate height and

tighten the inside nut to secure the arrangement,

Leveling Bolt Installation

Inches (mm)

3/8

Furnace Front _¢

3/8 1-3/4

(44)

1-3/4

(44)

Leveling Bolt

Locati,

Furnace

Bottom

Leveling Bolt

Locations

3/8

(10)

3/8 1-3/4

(10) (44)

I-3/4 (44)

FIGURE 8

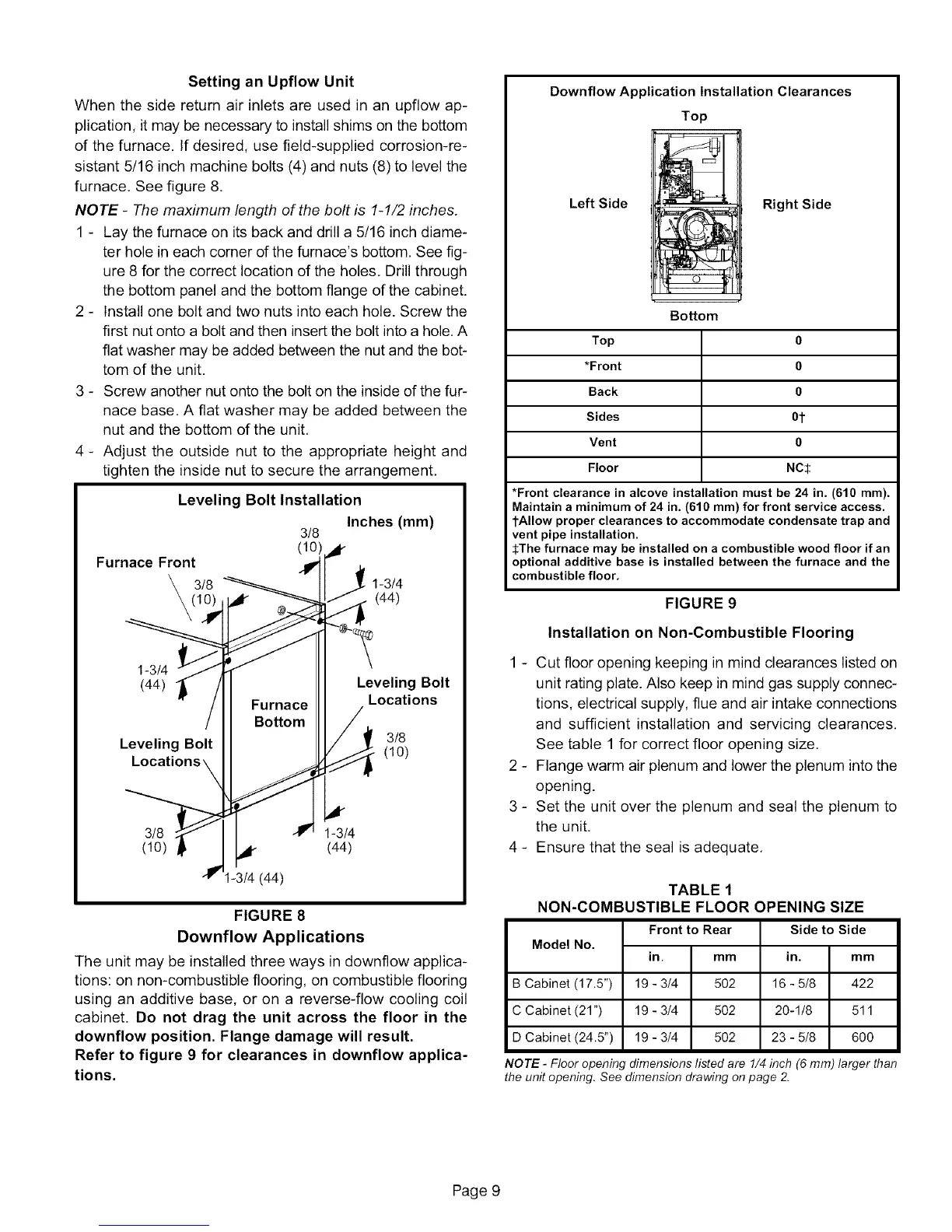

Downflow Applications

The unit may be installed three ways in downflow applica-

tions: on non-combustible flooring, on combustible flooring

using an additive base, or on a reverse-flow cooling coil

cabinet. Do not drag the unit across the floor in the

downflow position. Flange damage will result.

Refer to figure 9 for clearances in downflow applica-

tions.

Downflow Application Installation Clearances

Top

LeftSide _ Right Side

Boffom

Top 0

*Front 0

Back 0

Sides 0t

Vent 0

Floor NC$

*Front clearance in alcove installation must be 24 in. (610 ram).

Maintain a minimum of 24 in. (610 ram) for front service access.

tAllow proper clearances to accommodate condensate trap and

vent pipe installation.

SThe furnace may be installed on a combustible wood floor if an

optional additive base is installed between the furnace and the

combustible floor.

FIGURE 9

Installation on Non-Combustible Flooring

1 - Cut floor opening keeping in mind clearances listed on

unit rating plate. Also keep in mind gas supply connec-

tions, electrical supply, flue and air intake connections

and sufficient installation and servicing clearances,

See table 1 for correct floor opening size.

2 - Flange warm air plenum and lower the plenum into the

opening.

3 - Set the unit over the plenum and seal the plenum to

the unit,

4 - Ensure that the seal is adequate,

TABLE 1

NON-COMBUSTIBLE FLOOR

Front to Rear

Model No.

mm

B Cabinet (17.5") 502

CCabinet(21") 502

DCabinet(24.5") 502

in.

19 - 3/4

19 - 3/4

19 - 3/4

)PENING SIZE

Side to Side

in. mm

16 - 5/8 422

20-1/8 511

23 - 5/8 600

NOTE - Floor opening dimensions listed are 1/4 inch (6 mm) larger than

the unit opening. See dimension drawing on page 2.

Page 9

Loading...

Loading...