Page 49

E−Check Manifold Pressure

To correctly measure manifold prressure, the differential

pressure between the positive gas manifold and the nega-

tive burner box must be considered. Use pressure test

adapter kit (available as Lennox part 10L34) to assist in

measurement.

1 − Connect test gauge +" connection to manifold pres

sure tap on the gas vavle.

2 − Tee into the gas valve regulator vent hose and con-

nect test gauge −" connection.

3 − Start unit on low heat (40%) rate) and allow 5 min-

utes for unit to reach steady state.

4 − While waiting for the unit to stabilize, notice the

flame. Flame should be stable and should not lift from

burnere. Natural gas should burn blue.

5 − After allowing unit to stablize for 5 minutes, record

manifold pressure and compare to value given in table

42.

6 − Repeat stpes 3, 4 and 5 on high fire.

CAUTION

Do not attempt to make adjustments to the gas valve.

F− Proper Gas Flow (Approximate)

1 − Operate unit at least 15 minutes before checking gas

flow. Determine the time in seconds for one revolu-

tions of gas through the meter. A portable LP gas me-

ter (17Y44) is available for LP applications.

2 − Compare the number of seconds and the gas meter

size in table 39 to determine the gas flow rate. Multiply

the gas flow rate by the heating value to determine the

unit input rate. If manifold pressure is correct and the

unit input rate is incorrect, check gas orifices for proper

size and restriction.

3 − Remove temporary gas meter if installed.

NOTE − To obtain accurate reading, shut off all other gas

appliances connected to meter.

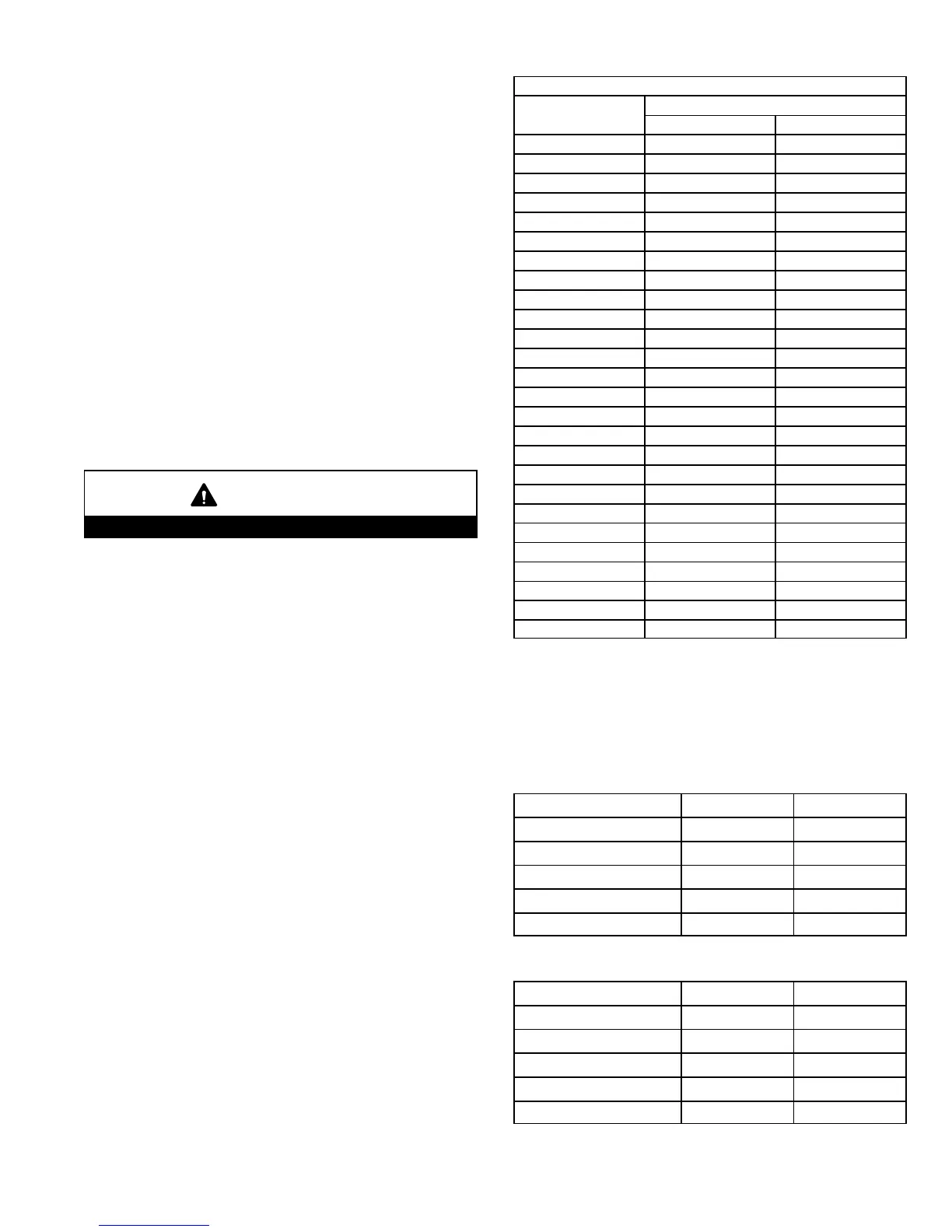

TABLE 39

Gas Flow Rate (Ft.

3

/Hr.)

Seconds for 1

Revolution

Gas Meter Size

1/2 cu ft Dial 1 cu ft Dial

10 180 360

12 150 300

14 129 257

16 113 225

18 100 200

20 90 180

22 82 164

24 75 150

26 69 138

28 64 129

30 60 120

32 56 113

34 53 106

36 50 100

38 47 95

40 45 90

42 43 86

44 41 82

46 39 78

48 38 75

50 36 72

52 35 69

54 33 67

56 32 64

58 31 62

60 30 60

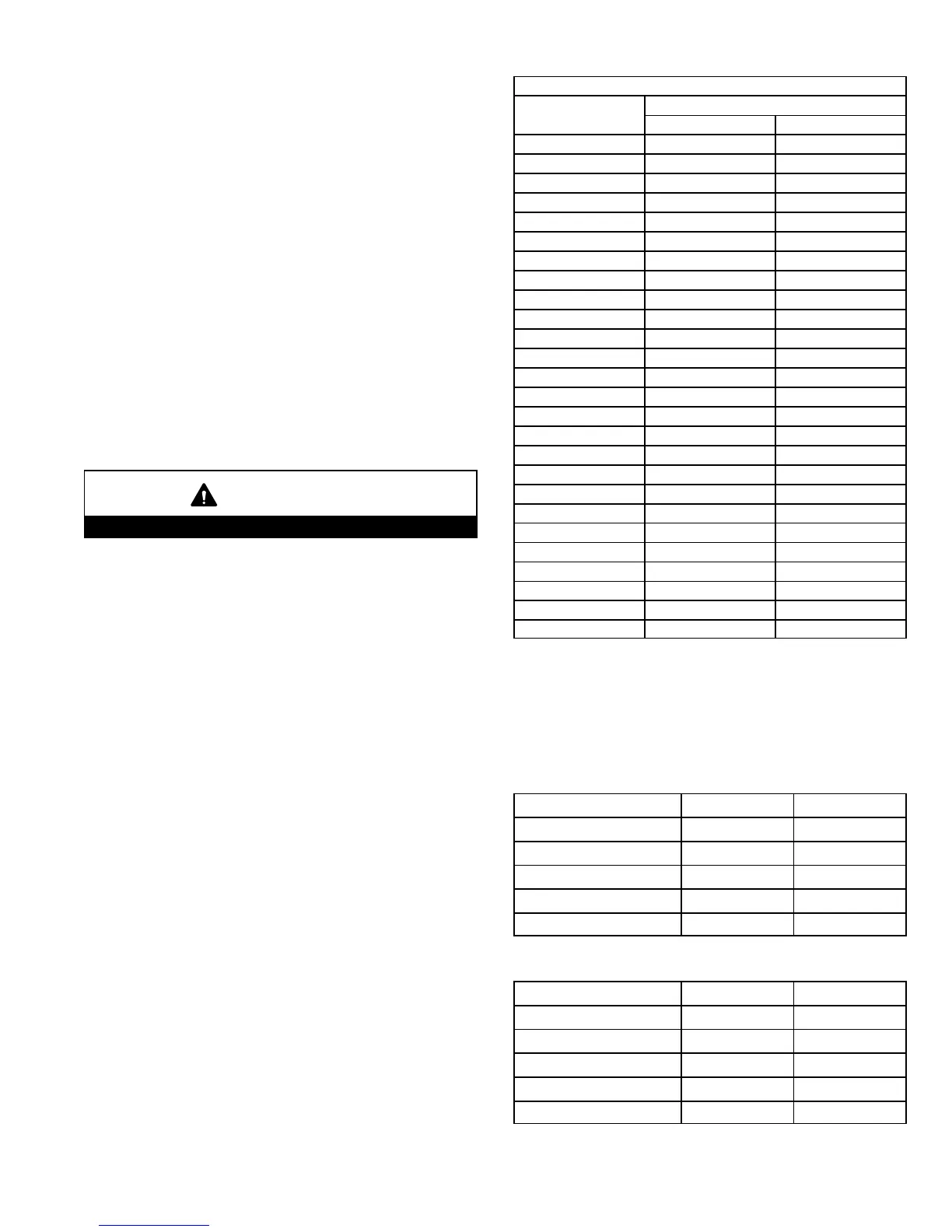

G− Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas flow rate before checking com-

bustion. Take combustion sample beyond the flue outlet

and compare to the tables below. The maximum carbon

monoxide reading should not exceed 100 ppm.

TABLE 40

High Fire

Unit

CO

2

%

For

Nat

CO

2

%

For

L.P.

G71MPP−36B−070 6.8 − 7.8 8.5 − 9.5

G71MPP−36C−090 7.2 − 8.2 8.5 − 9.5

G71MPP−60C−090 7.2 − 8.2 7.2 − 8.2

G71MPP−60C−110 7.6 − 8.6 7.6 − 8.6

G71MPP−60D−135 7.5 − 8.5 7.5 − 8.5

TABLE 41

Low Fire

Unit CO

2

%

For

Nat

CO

2

%

For

L.P.

G71MPP−36B−070 5.0 − 6.0 5.8 − 6.8

G71MPP−36C−090 4.9 − 5.9 5.7 − 6.7

G71MPP−60C−090 4.9 − 5.9 5.7 − 6.7

G71MPP−60C−110 5.0 − 6.0 6.2 − 7.2

G71MPP−60D−135 5.0 − 6.0 5.7 − 6.7

Loading...

Loading...