Page 10

Defrost Control CMC1

The defrost control board combines functions of a time /

temperature initiated and time / pressure terminated defrost

control, defrost relay, time delay, diagnostic LEDs and field

connection terminal strip. See figure 10.

The control provides automatic switching from normal

heating operation to defrost mode and back. During com

pressor cycle (call for defrost), the control accumulates

compressor run times at 30, 60 or 90 minute field adjust

able intervals. If the defrost thermostat remains closed

when the accumulated compressor run time ends, the de

frost relay is energized and defrost begins. The defrost

cycle is terminated by the defrost pressure switch or in 14

minutes whichever occurs first.

Defrost Control Components

1− Defrost Control Timing Pins

Each timing pin selection provides a different accumu

lated compressor run period during one thermostat run

cycle. This time period must occur before a defrost cycle

is initiated. The defrost interval can be adjusted to 30, 60

or 90 minutes. See figure 10. If no timing is selected, the

control defaults to the factory setting 90 minutes. The de

frost period is a maximum of 14 minutes and cannot be

adjusted.

A TEST option is provided for troubleshooting. When the

jumper is placed across the TEST pins, the timing of all

functions is reduced by a factor of 128. For example, a 90

minute interval during TEST is 42 seconds and the 14−min

ute defrost is reduced to 6.5 seconds.

The TEST mode may be started at anytime. If the jumper is

in the TEST position at power−up or for longer than five min

utes, the control will ignore the TEST selection and will de

fault to a 90 minute interval. In order to test defrost cycle,

defrost thermostat must be closed or jumpered. Once

defrost is initiated, remove jumper immediately. Failure to

remove jumper will reduce defrost time to seconds.

2− Time Delay

The timed−off delay is five minutes long. The delay feature

is provided to help protect the compressor in case of inter

ruption in power to the unit before thermostat demand is

satisfied, or when a pressure switch resets. If thermostat

demand is satisfied and the off cycle is greater than 5 min

utes, the compressor will energize immediately on next

heating or cooling demand.

3− Pressure Switch Safety Circuits

The defrost control incorporates a pressure switch safety

circuit that allows the application of an additional pressure

switch; high pressure switch (S4) is factory−wired to this cir

cuit. See figure 10. PS1 and PS2 terminals are internally

connected in series with a jumper internal to the control

board.

During one demand cycle, the defrost control will lock out

the unit on the third instance that the unit goes off on any

auto−reset pressure switch wired to this circuit. The diag

nostic LEDs will display a pattern for a locked out pressure

switch on the third open pressure switch occurrence. See

table 1. The unit will remain locked out until power is bro

ken then remade to the control.

The PS2 safety circuit terminals are connected to the com

pressor thermostat.

4− Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a specific sequence according to the condi

tion. See table 1.

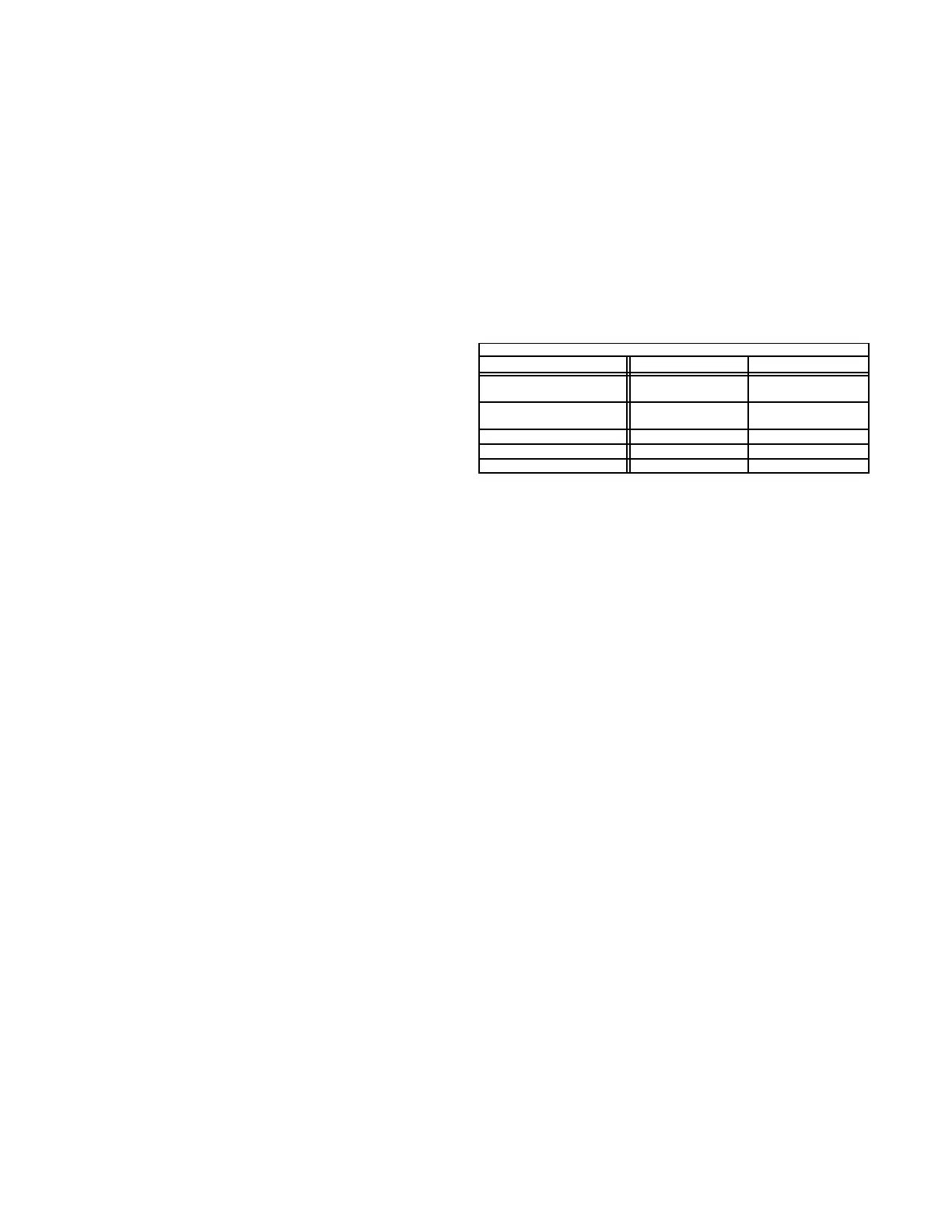

TABLE 1

DEFROST CONTROL BOARD DIAGNOSTIC LED

MODE LED 1 LED 2

Normal Operation/

Power to board

Flash together with

LED 2

Flash together with

LED 1

Time Delay

To Protect Compressor

Alternating Flashes

with LED 2

Alternating Flashes

with LED 1

Pressure Switch Open Off On

Pressure Switch Lockout On Off

Board Malfunction On On

5−Anti−Short Cycle

This feature of the board prevents the compressor from be

ing short−cycled which could result in damage. An internal

board timer prevents the compressor from being ener

gized for approximately 5 minutes, after thermostat de

mand is met. During this time off, the system refrigerant

pressure is able to equalize (between low and high sides)

which eases compressor start up.

6−Ambient (outdoor air) Thermistor

The defrost control board has two terminal connections for

an ambient thermistor. The thermistor compensates for

changes in the outdoor air temperature. This change in

temperature can cause thermostat droop. Droop may be

defined as the difference between the room thermostat

set−point and the lowest temperature of the indoor air once

the indoor blower is energized. Cool air (relative to thermo

stat set−point or desired room air temperature) will enter

the home when the indoor blower is energized. The therm

istor raises the thermostat set−point by a fractional amount

(1 or 2° F) to keep the indoor air temperature near the ther

mostat set−point.

7−Service Light Connection

Terminal connections W1, L and C are for the addition of a

thermostat service light. This light can be used with any

thermostat. It is powered from the W1 (second stage heat)

terminal of the indoor thermostat and is controlled by a dis

charge line thermostat (S54). The discharge line thermo

stat will close and activate the service light when discharge

line temperature drops below 110°F 5° during compres

sor operation. The light informs the home owner of a prob

lem with the system (specifically the compressor). When

the light is on, second stage heating may be initiated. The

normally closed thermostat will open when discharge line

reaches 130°F 5° which requires 30 to 40 seconds of

compressor operation, at which time the service light is de−

energized.

Loading...

Loading...