Page 13

II− REFRIGERANT SYSTEM

A−Plumbing

Field refrigerant piping consists of liquid and vapor lines

from the outdoor unit (sweat connections) to the indoor

evaporator coil (sweat connections). Refer to table 2 for

field−fabricated refrigerant line sizes. Refer to Lennox Re

frigerant Piping manual Corp. #9351−L9 for proper size,

type and application of field−fabricated lines. Separate dis

charge and suction service ports are provided at the com

pressor for connection of gauge manifold during charging

procedure.

B−Accumulator

All HP29−2 units are equipped with an accumulator. The

accumulator prevents compressor slugging by holding ex

cess refrigerant and then slowly metering it back into the

system.

TABLE 2

REFRIGERANT LINE SIZES

HP29

UNIT

LIQUID

LINE

VAPOR

LINE

090

5/8 in

(16 mm)

1−3/8 in

(35mm)

120 5/8 in

(16 mm)

1−3/8 in

(35mm)

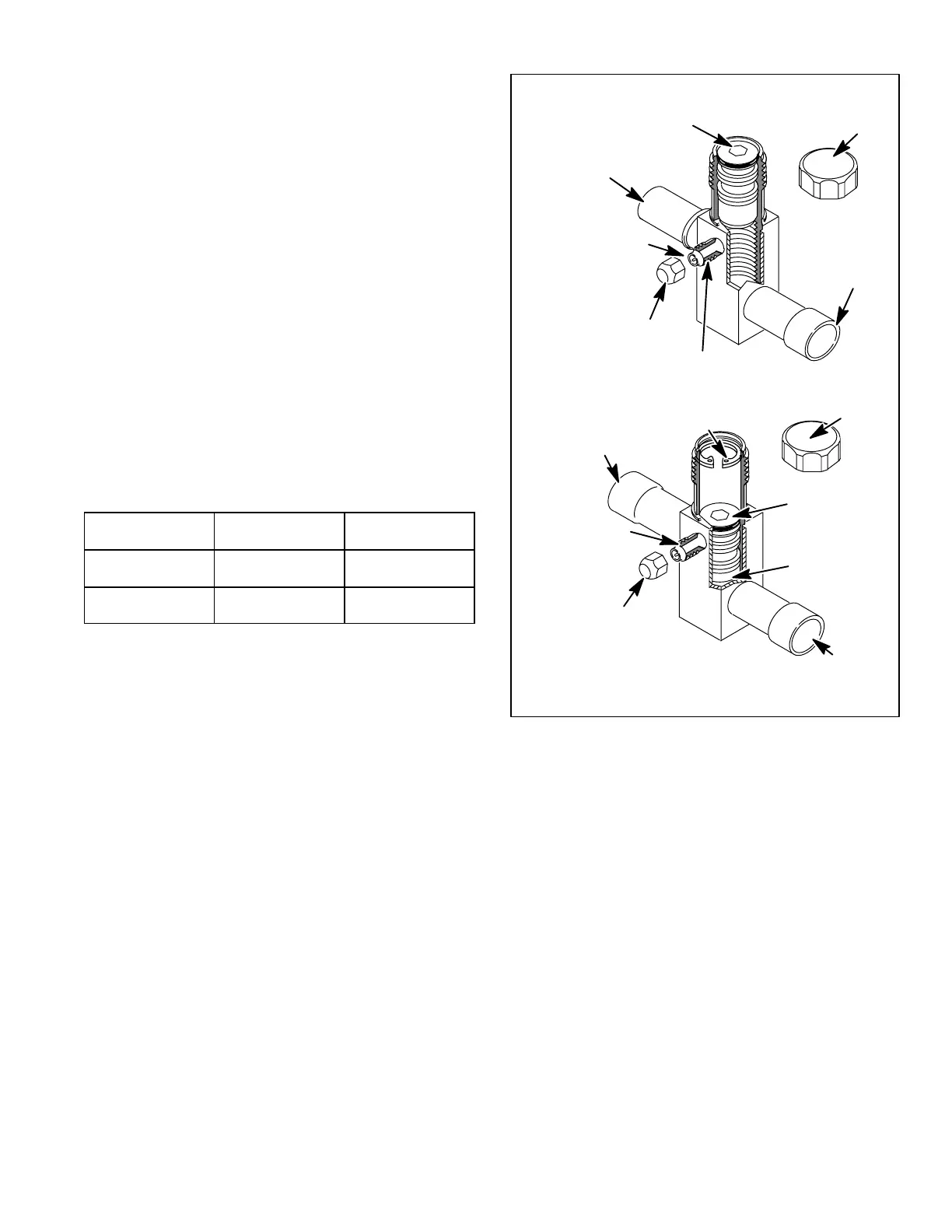

C−Service Valves

All HP29 units are equipped with service valves located in

the liquid and vapor lines. The service valves are manually

operated. See figures 14 and 15. The service ports are

used for leak testing, evacuating, charging and checking

charge.

1 − Liquid Line Service Valve

A fullservice liquid line valve made by one of several

manufacturers may be used. All liquid line service valves

function the same way, differences are in construction.

Valves are not rebuildable. If a valve has failed, it must be

replaced. The liquid line service valve is illustrated in figure

14.

A schrader valve is factory installed. A service port cap is

supplied to protect the schrader valve from contamination

and to serve as primary leak seal.

FIGURE 14

LIQUID LINE SERVICE VALVE (VALVE OPEN)

VALVE

CORE

SERVICE PORT

SERVICE PORT

CAP

INSERT HEX

WRENCH HERE

INLET (TO

INDOOR COIL)

OUTLET (TO

COMPRESSOR)

STEM CAP

VALVE CORE OPEN

TO LINE SET WHEN VALVE IS

CLOSED (FRONT SEATED)

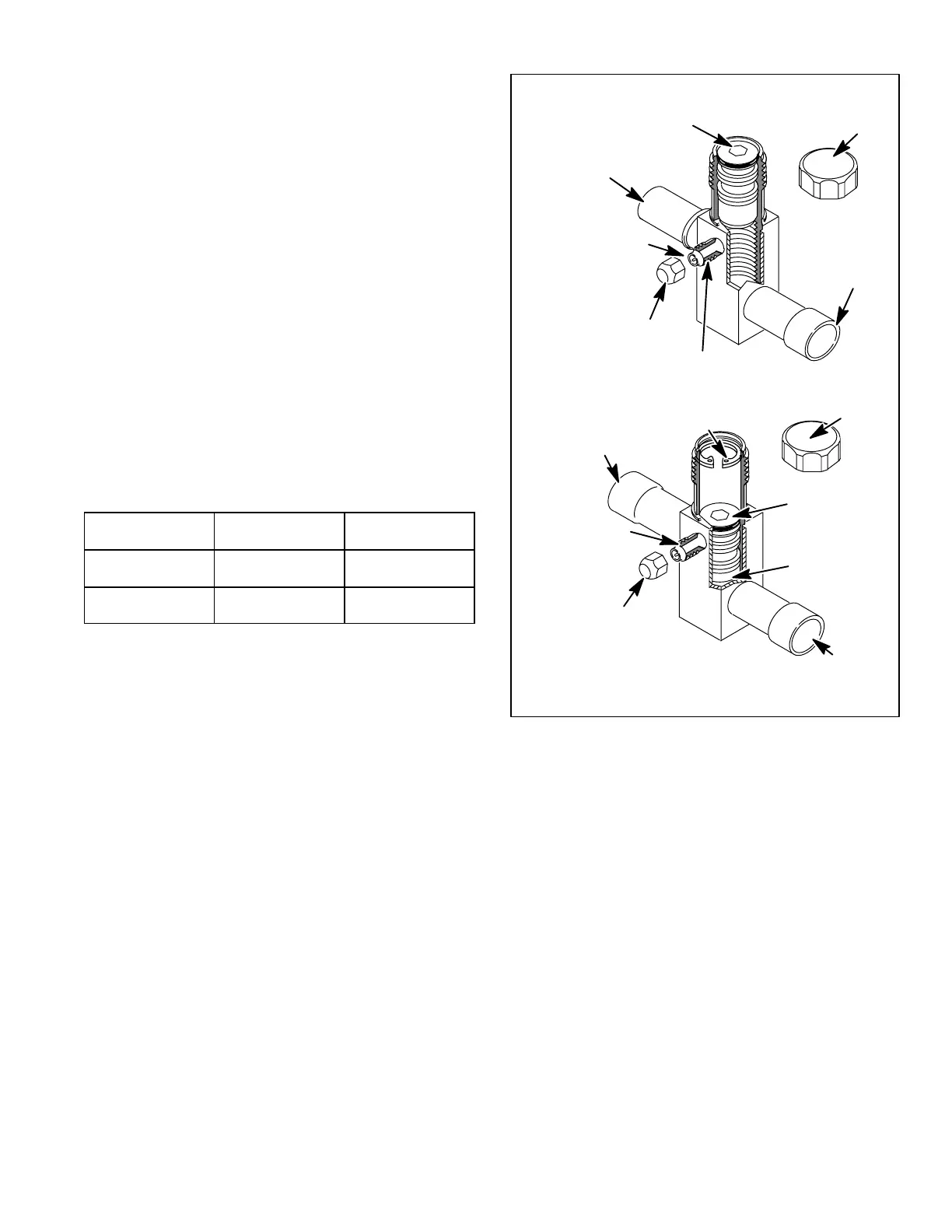

SERVICE

PORT

SERVICE PORT

CAP

RETAINING RING

(−2 units only)

STEM CAP

INSERT HEX

WRENCH HERE

LIQUID LINE SERVICE VALVE (VALVE CLOSED)

(VALVE FRONT

SEATED)

INLET (TO

INDOOR COIL)

OUTLET (TO

COMPRESSOR)

To Access Service Port:

1 − Remove service port cap with an adjustable wrench.

2 − Connect gauge to the service port.

3 − When testing is completed, replace service port cap.

Tighten finger tight, then an additional 1/6 turn. Do not

over−torque.

Open Liquid Line Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − Using service wrench and 5/16" hex head extension (part

#49A71) back the stem out counterclockwise until the

valve stem just touches the retaining ring. Make sure

wrench fits properly to avoid stripping stem.

3 − Replace stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

Loading...

Loading...