Page 17

C−Charging

If the system is completely void of refrigerant, the recom

mended and most accurate method of charging is to weigh

the refrigerant into the unit according to table 3.

If weighing facilities are not available or if unit is just low on

charge, the following procedure applies.

The following procedures are intended as a general

guide for use with expansion valve systems only. For

best results, indoor temperature should be between 70

°F(21_C) and 80 °F (26.6 C_). Outdoor temperature

should be 60 °F (15.5 C_) or above. Slight variations in

charging temperature and pressure should be ex

pected. Large variations may indicate a need for further

servicing.

IMPORTANT

Use tables 5 and 6 as a general guide for performing

maintenance checks. Tables 5 and 6 are not a pro

cedure for charging the system. Minor variations in

these pressures may be expected due to differ

ences in installations. Significant deviations could

mean that the system is not properly charged or that

a problem exists with some component in the sys

tem. Used prudently, table 5 could serve as a useful

service guides.

IMPORTANT

The following procedure requires accurate read

ings of ambient (outdoor) temperature, liquid tem

perature and liquid pressure for proper charging.

Use a thermometer with accuracy of +2 °F and a

pressure gauge with accuracy of +5 PSIG.

1 − Attach gauge manifolds and operate unit in cooling

mode until system stabilizes (approximately 5 min

utes).

2 − Check each circuit separately with all stages operat

ing.

3 − Use a thermometer to accurately measure the outdoor

ambient temperature.

4 − Apply the outdoor temperature to table 5 or 6 to deter

mine normal operating pressures.

5 − Compare the normal operating pressures to the pres

sures obtained from the gauges. Minor variations in

these pressures may be expected due to differences

in installations. Significant differences could mean that

the system is not properly charged or that a problem

exists with some component in the system. Correct

any system problems before proceeding.

6 − If liquid pressure is high, remove refrigerant from the

system. If discharge pressure is low, add refrigerant to

the system.

D Add or remove charge in increments.

D Allow the system to stabilize each time

refrigerant is added or removed.

7 − Use the following approach method along with the nor

mal operating pressures to confirm readings.

APPROACH METHOD (TXV SYSTEMS)

(Ambient Temperature of 60_F [16_C] or above)

1 − Use the same thermometer to take both the liquid

line temperature and the outdoor ambient tempera

ture. Compare liquid line temperature to the outdoor

ambient temperature. Approach temperature

equals the liquid line temperature minus the outdoor

ambient temperature.

2 − The approach temperature should match values giv

en in table 4. An approach temperature greater than

the value shown indicates an undercharge. An ap

proach temperature less than the value shown indi

cates an overcharge.

3 − Do not use the approach method if system pres

sures do not match the pressures given in table

5. The approach method is not valid for grossly

over or undercharged systems.

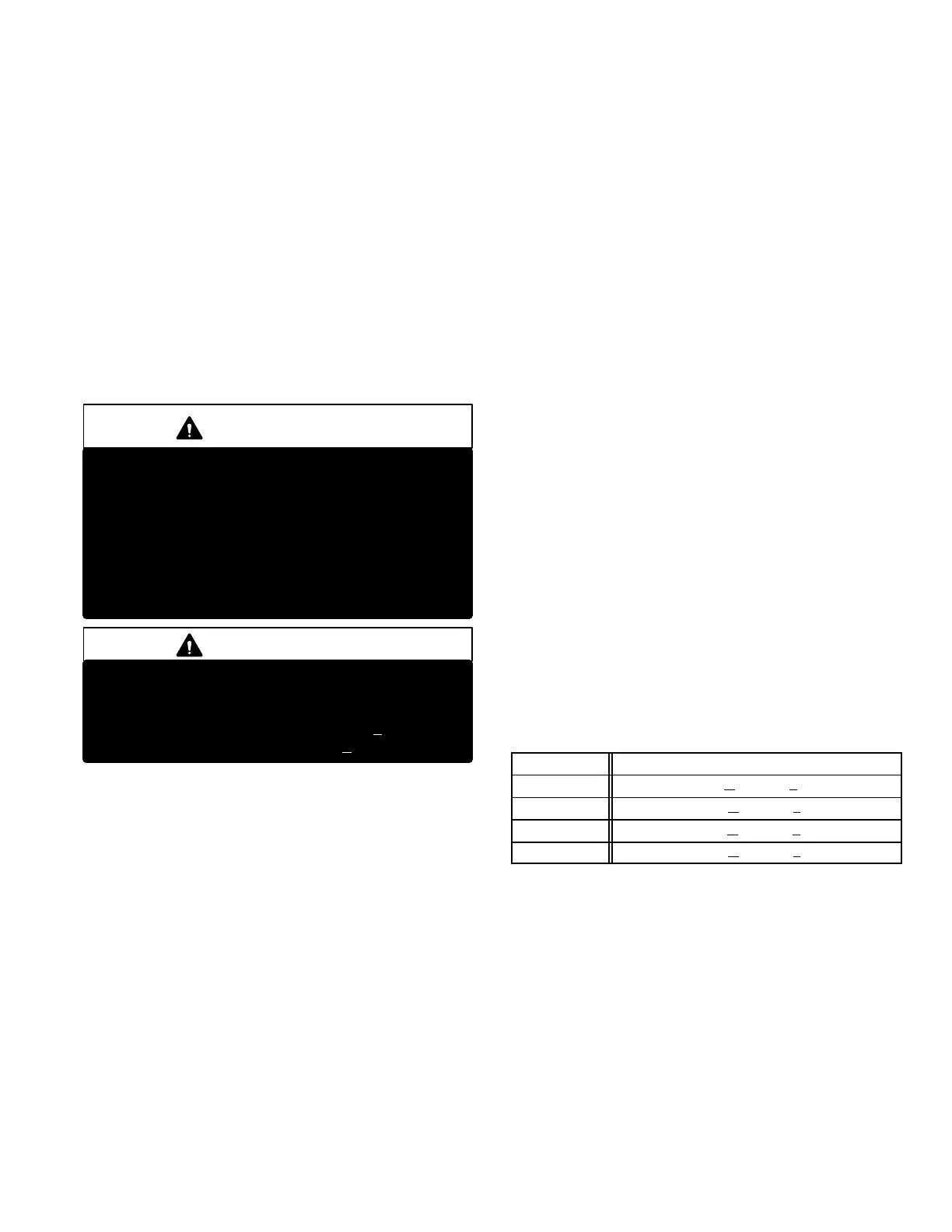

TABLE 4

MODEL NO. LIQUID TEMP. MINUS AMBIENT TEMP. _F (_C)

HP29−090−2 9.2_F + 1 (5.0_C + 0.5)

HP29−090−3 14.5_F + 1 (8.0_C + 0.5)

HP29−120−2 11.3_F + 1 (6.0_C + 0.5)

HP29−120−3 10.0_F + 1 (5.6_C + 0.5)

Note− For best results, the same thermometer should be used to

check both outdoor ambient and liquid temperatures.

D−Oil Charge

Refer to compressor nameplate.

Loading...

Loading...