Page 8

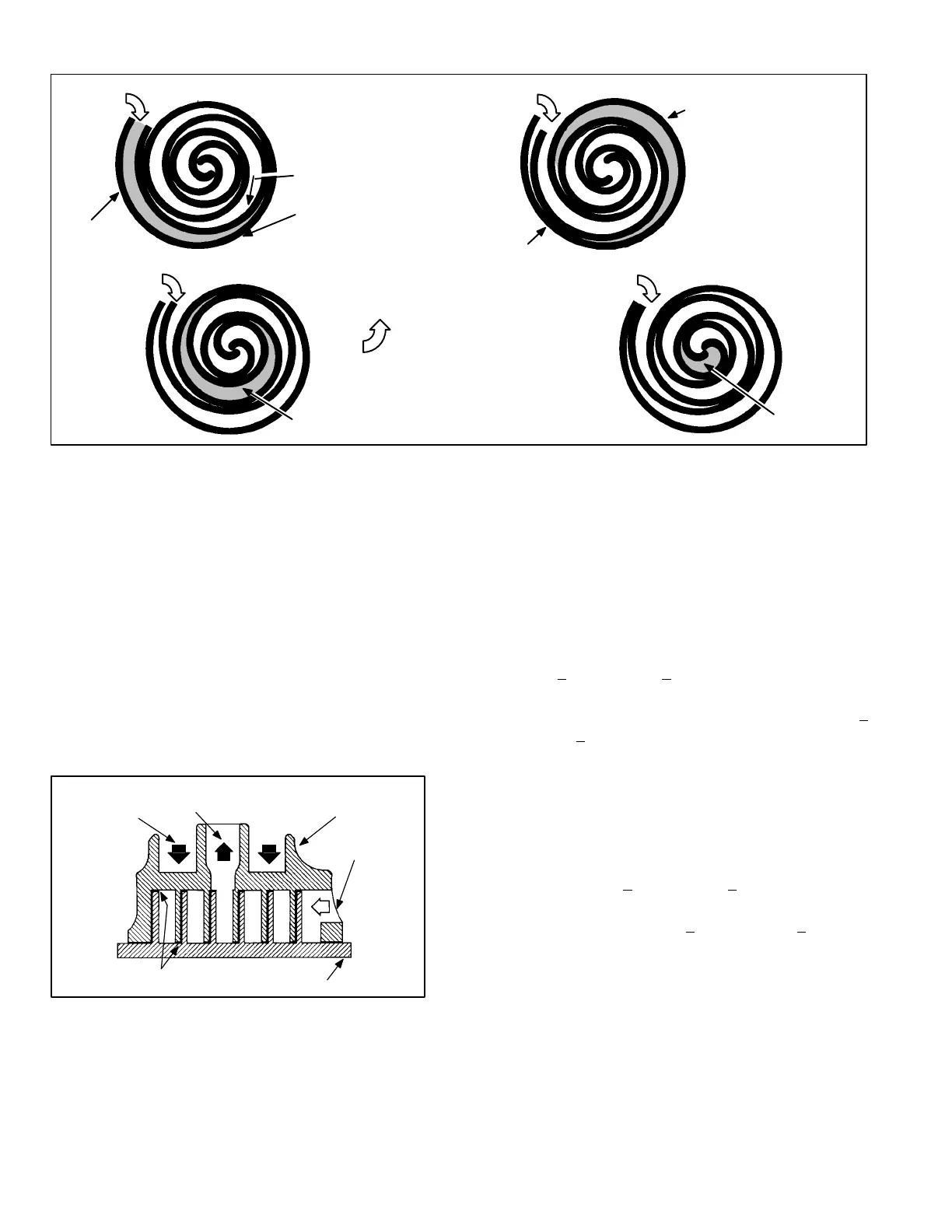

FIGURE 8

1

2

3

4

SUCTION

POCKET

SUCTION

ORBITING SCROLL

STATIONARY SCROLL

SUCTION

SUCTION

DISCHARGE

POCKET

SUCTION

INTERMEDIATE PRESSURE

GAS

CRECENT SHAPED

GAS POCKET

HIGH PRESURE GAS

FLANKS SEALED

BY CENTRIFIGUAL

FORCE

MOVEMENT OF ORBIT

The counterclockwise orbiting scroll draws gas into the

outer crescent shaped gas pocket created by the two

scrolls (figure 8−2). The centrifugal action of the orbiting

scroll seals off the flanks of the scrolls (figure 8−3). As the

orbiting motion continues, the gas is forced toward the cen

ter of the scroll and the gas pocket becomes compressed

(figure 8−4).

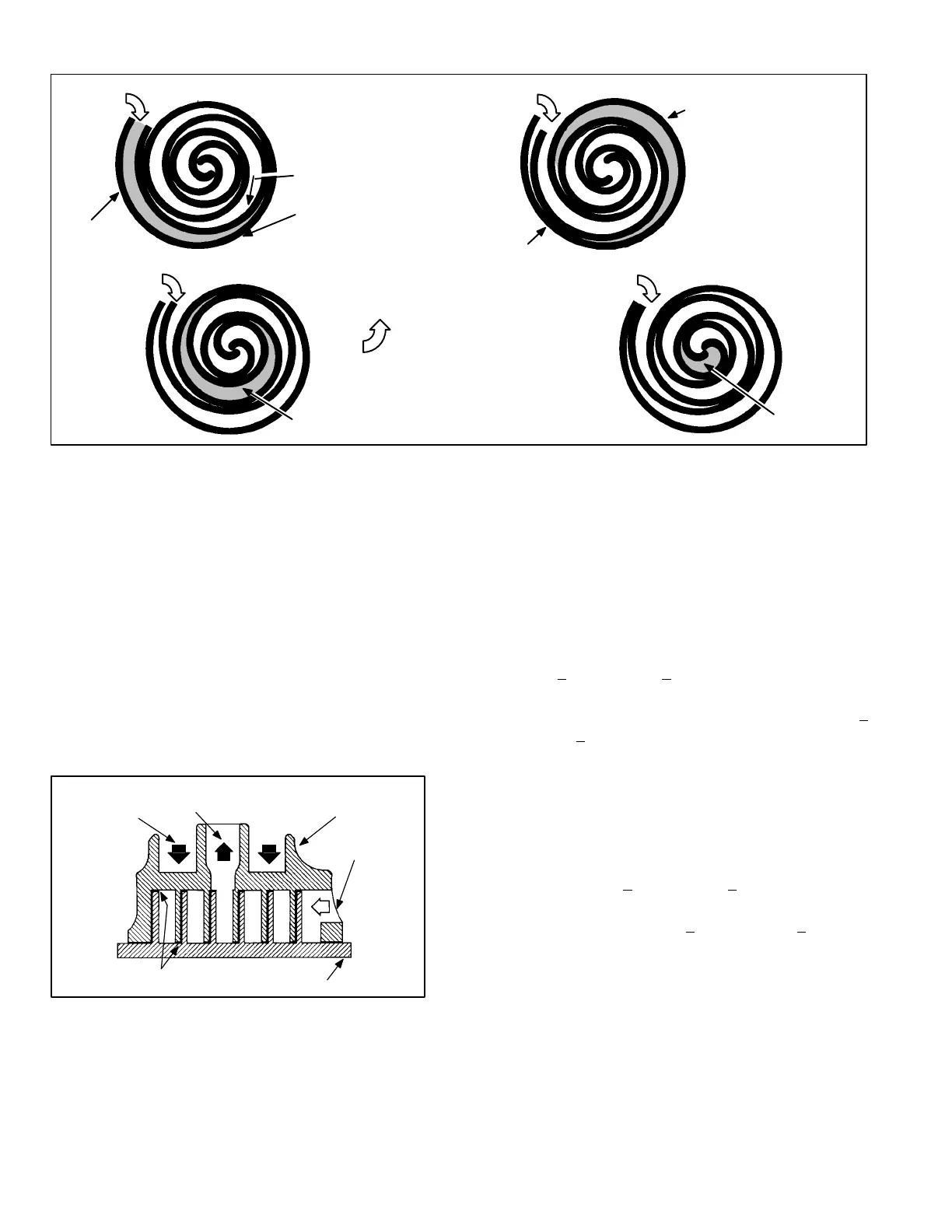

When compressed gas reaches the center, it is discharged

vertically into a chamber and discharge port in the top of

the compressor (figure 6). The discharge pressure forcing

down on the top scroll helps seal the upper and lower

edges (tips) of the scrolls (figure 9). During a single orbit,

several pockets of gas are compressed simultaneously

providing smooth continuous compression.

STATIONARY SCROLL

ORBITING SCROLL

DISCHARGE

SUCTION

CROSS−SECTION OF SCROLLS

TIPS SEALED BY

DISCHARGE PRESSURE

DISCHARGE

PRESSURE

FIGURE 9

2 − Crankcase Heaters HR1 (all units)

All HP29 units use a belly−band crankcase heater. Heater

HR1 is wrapped around compressor B1. HR1 assures

proper compressor lubrication at all times.

3 − High Pressure Switch S4 (all units)

The high pressure switch is a manual−reset SPST N.C.

switch which opens on a pressure rise. The switch is lo

cated on the compressor discharge line and is wired to the

defrost control board CMC1. When discharge pressure

rises to 450 + 10 psig (3103 + 69 kPa) the switch opens and

the compressor is de−energized through the CMC1. The

switch will close when discharge pressure drops to 300 +

20 psig (2068 + 138 kPA).

4 − Low Ambient Switch S11 (all units)

The low ambient switch is an auto−reset SPST N.O. pres

sure switch, which allows for mechanical cooling operation

at low outdoor temperatures. All HP29 units are equipped

with S11. The switch is located in the liquid line. In all HP29

units, S11 is wired in series with fan relay K10. When liquid

pressure rises to 275 + 10 psig (1896 + 69 kPa), the switch

closes and the condenser fan is energized. When the dis

charge pressure drops to 150 + 10 psig (1034 + 69 kPa),

the switch opens and the condenser fan is de−energized.

This intermittent fan operation results in higher evaporat

ing temperature, allowing the system to operate without ic

ing the evaporator coil and losing capacity.

Loading...

Loading...