INNOV@ ECFAN DMR -AGU-0912-E • 21 •

10.3 Checking the refrigerant level (DX version)

D After a few hours of operation, check whether the liquid level indicator has a green ring: a yellow colour indicates the

presence of humidity in the circuit. In such a case the circuit must be dehumidified by qualified personnel.

D Large quantities of bubbles should not appear through the liquid level indicator. A constant passage of numerous

bubbles may indicate that the refrigerant level is low and needs to be topped up. The presence of a few bubbles is

however allowed, especially in the case of high-glide ternary mixtures such as HFC R407C.

D Make sure the overheating of the cooling fluid is limited to between 5 and 8 °C: to this end:

1 ) read the temperature indicated by a contact thermometer placed on the compressor intake pipe;

2 ) read the temperature indicated on the scale of a pressure gauge likewise connected to the intake side; refer to

the pressure gauge scale for the refrigerant R407C, marked with the initials D.P. (Dew Point).

D Make sure that the Sub-cooling of the cooling fluid is limited to between 3 and 5°C: to this end:

1 ) read the temperature indicated by a contact thermometer placed on the condenser outlet pipe;

2 ) read the temperature indicated on the scale of a pressure gauge connected to the liquid inlet at the condenser

outlet; refer to the pressure gauge scale for the refrigerant R407C, marked with the initials B.P. (Bubble Point).

The degree of Sub-cooling is given by the difference between the temperatures thus determined.

Warning: All INNOV@DM-R DX units are charged with dry nitrogen and you must empty them

before charging with refrigerant. This operation must be performed by qualified

personnel only.

Warning: Any top-ups must be made using R407C only. This operation is to be considered

extraordinary maintenance work and must be performed by qualified personnel only.

Warning: The refrigerant R407C requires “POE“ polyolester oil of the type and viscosity indicated

on the compressor rating plate.

For no reason should oil of a different type be introduced into the oil circuit.

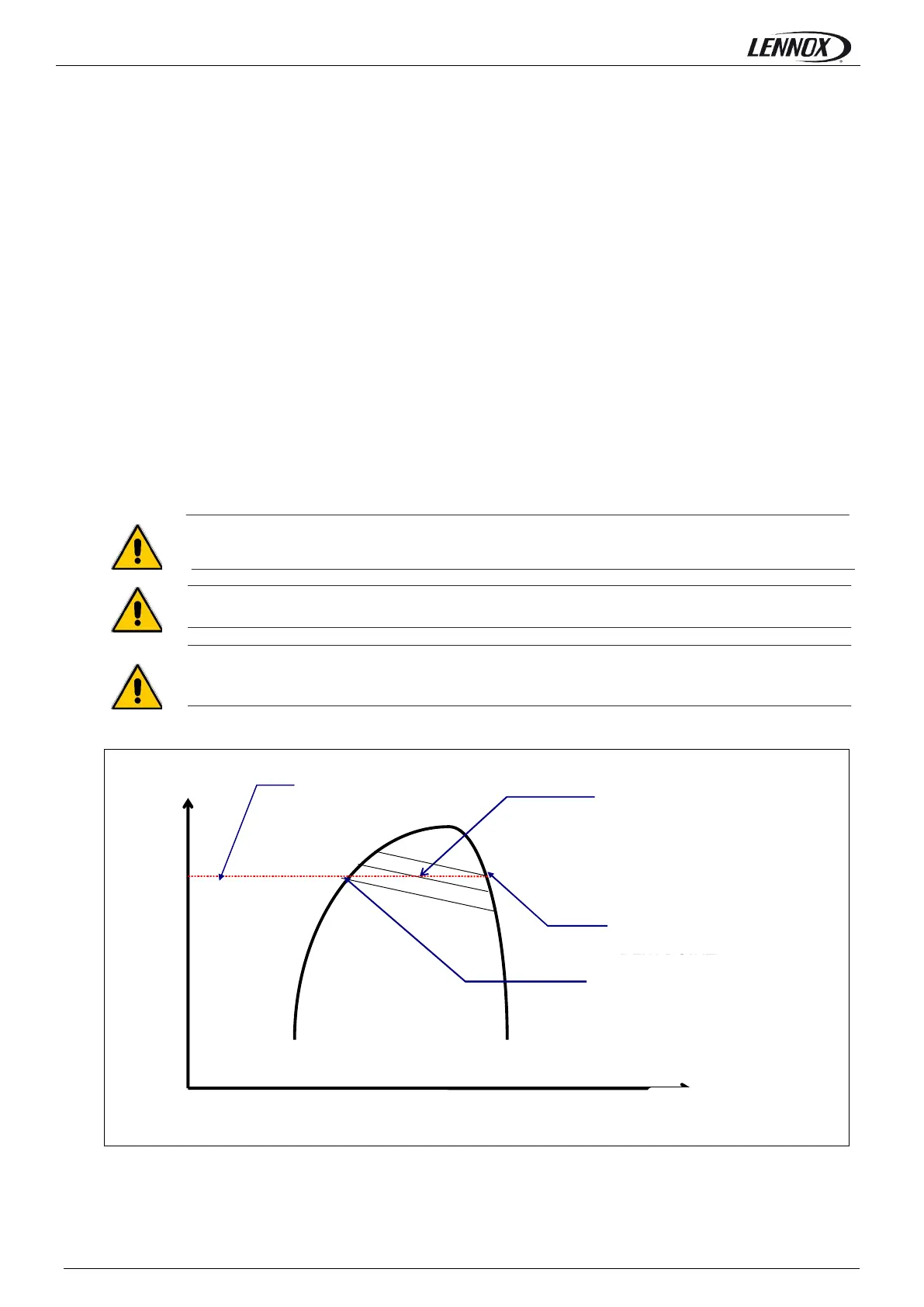

The difference between the “Dew Point” and “Bubble Point” is known as “GLIDE” and this is a characteristic property of

refrigerant mixtures. If pure fluids are used, the phase change occurs at a constant T and thus the glide is equal to zero.

Average T

(T1+T2)/2

T1 (start of

condensation)

T2 (end of condensation)

BUBBLE POINT

Enthalpy h

P

Real P

Compressor

Outlet

R407C

Loading...

Loading...