Page 15

11-Power Exhaust Relay K65 (PEF units)

Power exhaust relay K65 is a DPDT relay with a 24VAC

coil. K65 is used in all LGA/LCA units equipped with the

optional power exhaust fans. K65 is energized by the

economizer control panel (A56), after the economizer

dampers reach 50% open (adjustable in ECTO). When

K65 closes, the exhaust fan B10 is energized.

12-Blower Motor Overload Relay S42 (units

with high efficiency motors)

The blower motor overload relay is used in all L series units

equipped with high efficiency motors. The relay (S42) is con-

nected in line with the blower motor to monitor the current flow

to the motor. When the relay senses an overload condition, a

set of normally closed contacts open to de-energize pin #9 in

plug 110 of the A55 main control module. A55 de-energizes all

outputs. The overload relay has an adjustable setting and is

set per the nameplate current of the motor. All units are

equipped with a relay manufactured by Siemens which is de-

tailed in figure 5.

13-Start Capacitor C7 (single-phase)

Single-phase units use a start capacitor (C7) wired in

parallel with the compressor side of the dual capacitor.

The start capacitor is located to the side of the control-

panel. C7 is engaged during compressor start-up and is

switched off by the potential relay as the compressor

nears full speed. Capacitor ratings may be different for

each motor, but the rating and repair part number will be

printed on the side of the capacitor.

14-Potential Relay K31 (single-phase)

Single-phase units use a potential relay which controls the op-

eration of the starting circuit. The potential relay is located to

the side of the unit control panel. The relay is normally closed

when the compressor (contactor K1) is de-energized. Capaci-

tor (C7) is connected to a set of N.C. K31 contacts and is used

to assist the compressor in starting. When K1 energizes, the

compressor immediately begins start-up. K31 remains de-en-

ergized during compressor start-up and the start capacitor

(C7) remains in the circuit. As the compressor gains speed,

K31 is energized by electromotive forces generated by the

compressor. When K31 energizes, its contacts open to take

the start capacitor out of the circuit.

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during furnace

installation and service to protect the furnace’s

electronic controls. Precautions will help to avoid

control exposure to electrostatic discharge by

putting the furnace, the control and the techni-

cian at the same electrostatic potential. Neutral-

ize electrostatic charge by touching hand and all

tools on an unpainted unit surface, such as the

gas valve or blower deck, before performing any

service procedure.

Precautions and Procedures

INTEGRATED MODULAR CONTROL BOARDS

The Integrated Modular Control (IMC) is a series of control

boards which integrates most control functions required for the

LGA/LCA units. The control boards are located in the upper

left hand corner of the control box. The control includes

complete unit diagnostics with permanent code storage,

field programmable control parameters and control op-

tions, on-site testing, and serial communications. Two

different printed circuit boards(see figure6) make-upthe

modular configurations for the LGA/LCA units. See table

2 for a list of control panels used for each unit. For further

information refer to Integrated Modular Control Guide sent with

each unit.

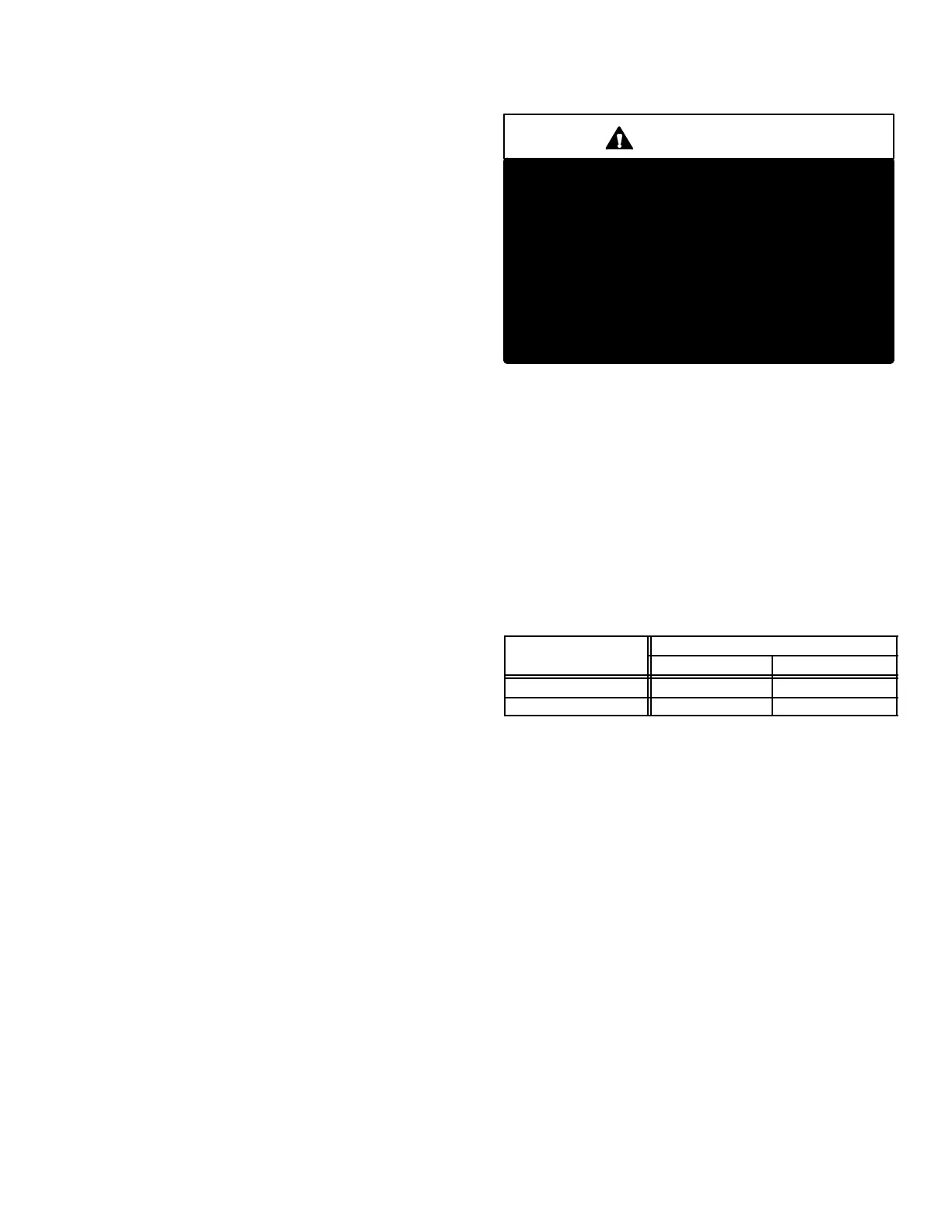

TABLE 2

CONTROL PANELS

A55 A56

LGA X OPT

LCA X OPT

15-Main Control Module A55 (all units)

The main control module A55 is the heart of the system. It

controls one compressor, one single or two stage gas

valve, one bank of electric heat, one outdoor fan, and one

blower.A55 includesthe thermostatinputs, serial commu-

nications ports, diagnostic code display, control pushbutton,

system configuration dip switches, and fourexpansion ports. A

diagnostic code list is located on the back side of the access

panel.

16-Economizer Control Module A56

(Economizer only)

The economizer control module A56 controls the econo-

mizer. A56 has four different cooling modes, sensible

temperature, outdoor enthalpy, differential enthalpy, and

global control.

Loading...

Loading...