Page 23

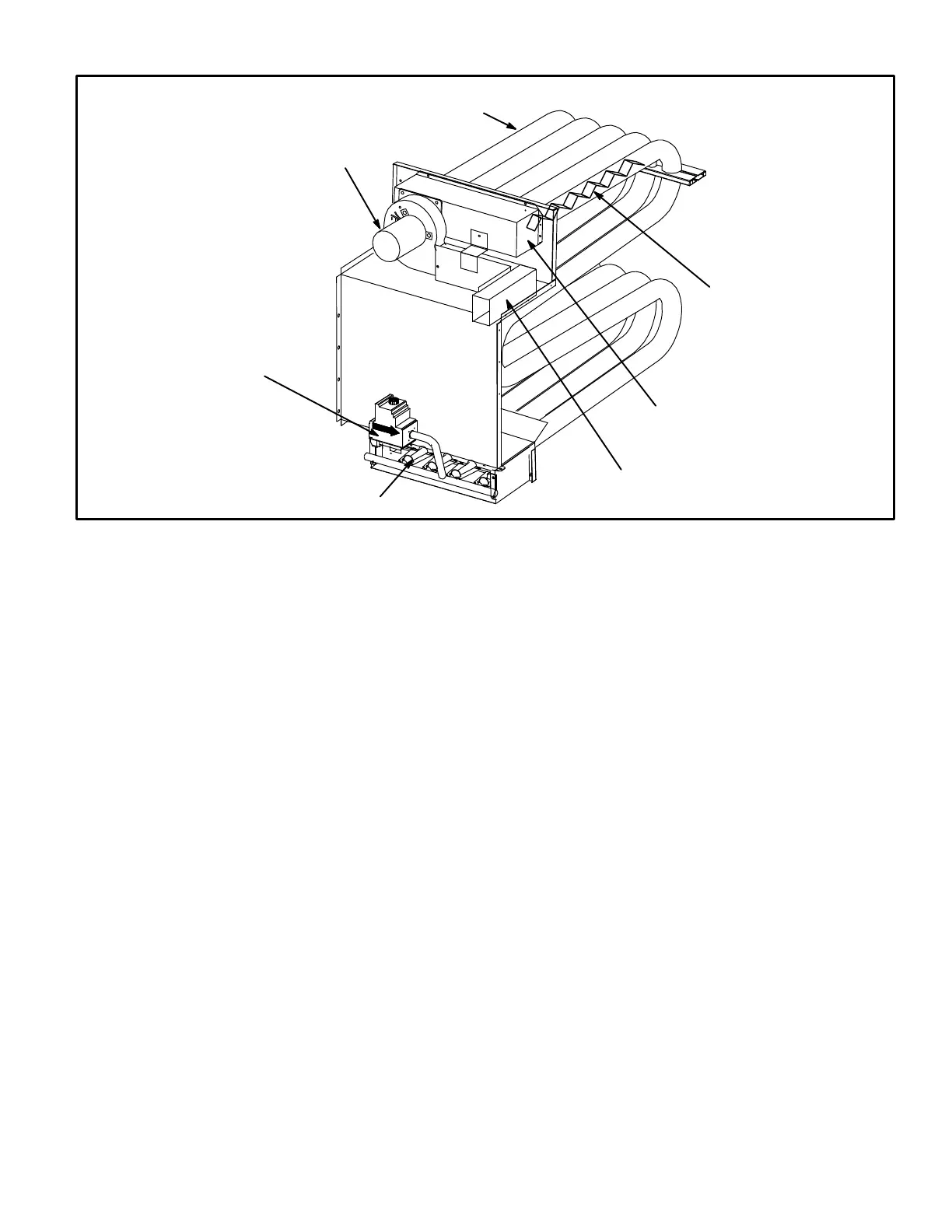

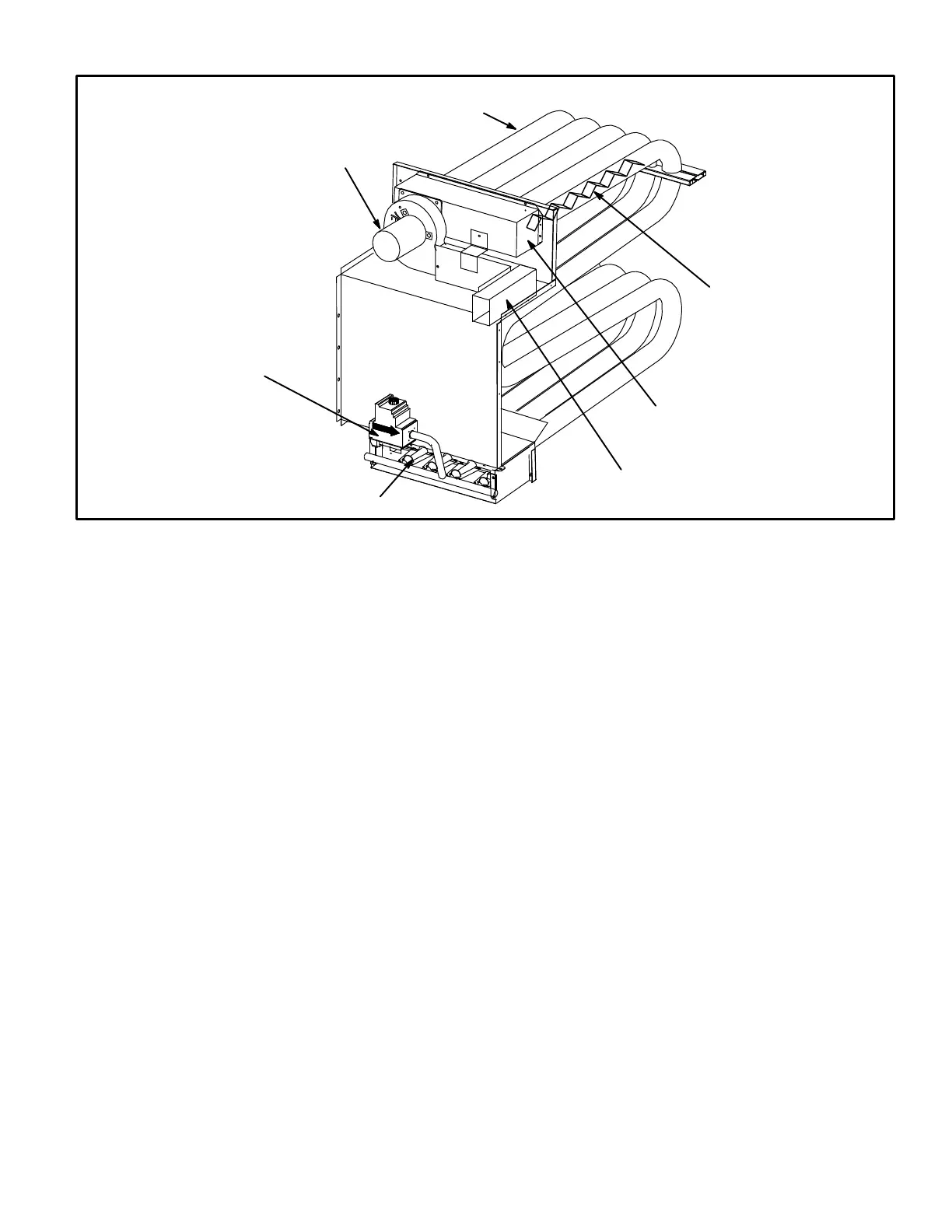

FIGURE 13

FLUE BOX

VENT CONNECTOR

BAFFLE

HEAT EXCHANGER TUBE

COMBUSTION AIR BLOWER

GAS

VALVE

BURNERS

LGA HEAT EXCHANGER

E-GAS HEAT COMPONENTS (LGA units)

LGA036 units are available in 78,000 Btuh (22.9 kW)

(standard gas heat only). LGA042/048/060/072 units

are available in 78,000 Btuh (22.9 kW) (standard gas

heat); 125,000 Btuh (36.6 kW) (high gas heat) or92,000

Btuh / 125,000 Btuh (27 / 36.6 kW) (two-stage gas heat)

sizes.

1-Burner Ignition Control A3

The ignition control is located below the control box. Three dif-

ferent manufacturers’ (Fenwal, Johnson Controls, and RAM)

controls are used in the LGA units. All three ignition controls

operate the same.

The ignition control provides three main functions: gas

valve control, ignition, and flame sensing. The unit will

usually ignite on the first attempt; however, the ignition at-

tempt sequence provides three trials for ignition before

locking out. The lockout time for the Johnson control is 5 min-

utes. The lockout time for the Ram control and Fenwall control

is 1 hour. After lockout the ignition control automatically re-

sets and provides three more attempts at ignition. Manual

reset after lockout requires breaking and remaking power to

the ignition control. See figure 15 for a normal ignition se-

quence and figure 16 for the ignition attempt sequence

with retrials (nominal timings given for simplicity). Specific

timings for the ignition controls are shown in figure 17.

Flame rectification sensing is used on all LGA units.

Loss of flame during a heating cycle is indicated by an ab-

sence of flame signal (0 microamps). If this happens, the con-

trol will immediately restart the ignition sequence and then lock

out if ignition is not gained after the third trial. See System

Service Check section for flame current measurement.

The control shuts off gas flow immediately in the event of a

power failure. Upon restoration of gas and power, the control

will restart the ignition sequence and continue until flame is

established or system locks out.

On a heating demand, the ignition control is energized by the

main control module A55. The ignition control then allows 30

seconds for the combustion air blower to vent exhaust gases

from the burners. When the combustion air blower is purging

the exhaust gases, the combustion air prove switch is closing

proving that the combustion air blower is operating before al-

lowing the ignition control to energize. When the combustion

air prove switch is closed and the delay is over, the ignition

control activates gas valve, the spark electrode and the

flame sensing electrode. Sparking stops immediately after

flame is sensed. The combustion air blower continues tooper-

ate throughout the heating demand. If the flame fails or if the

Loading...

Loading...