Page 6507246-02 7/2018

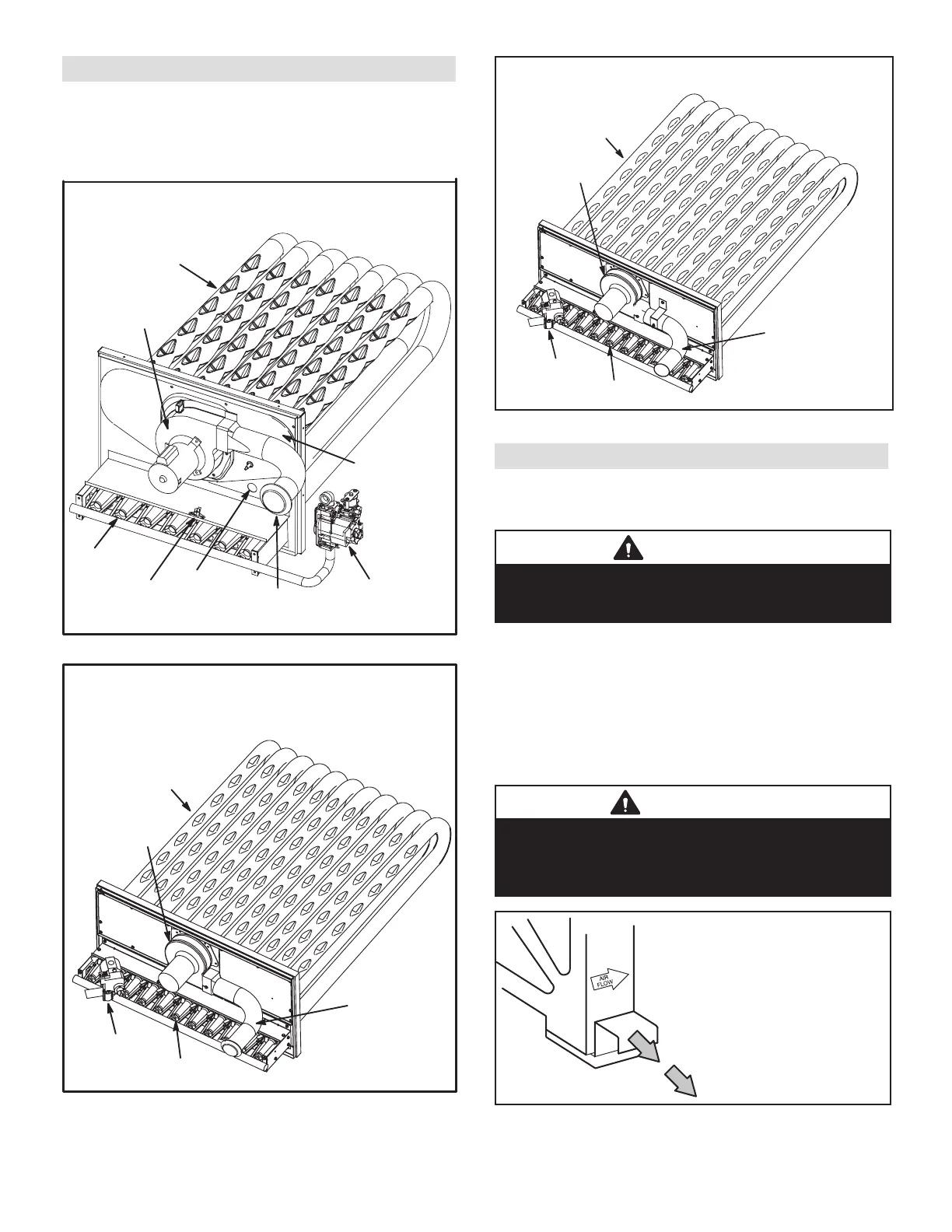

Flue Passage and Vent Inspection

Annually, before heating season, inspect the combustion

air louvers, vent cap, heat exchanger, burners and com-

bustion air inducer for corrosion, deterioration or deposits

of debris. Remove any obstructions or blockage. See Fig-

ure 5, Figure 6, or Figure 7.

HEAT EXCHANGER ASSEMBLY

036-074 UNITS - Single- and Two-Stage Shown

BURNER

COMBUSTION

AIR INDUCER

VENT

CONNECTOR

GAS VALVE

HEAT

EXCHANGER

TUBE

PRIMARY

LIMIT

ROLLOUT

SWITCH

FLUE BOX

COVER

FIGURE 5

HEAT EXCHANGER ASSEMBLY

092-152 UNITS

BURNER

COMBUSTION

AIR INDUCER

VENT

CONNECTOR

GAS VALVE

HEAT

EXCHANGER

TUBE

FIGURE 6

HEAT EXCHANGER ASSEMBLY

156-360 UNITS

BURNER

COMBUSTION

AIR INDUCER

VENT

CONNECTOR

GAS VALVE

HEAT

EXCHANGER

TUBE

FIGURE 7

Service

To maintain efciency and longevity, your equipment

must be serviced yearly by a qualied service technician.

Failure to provide proof of service can void warranty.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

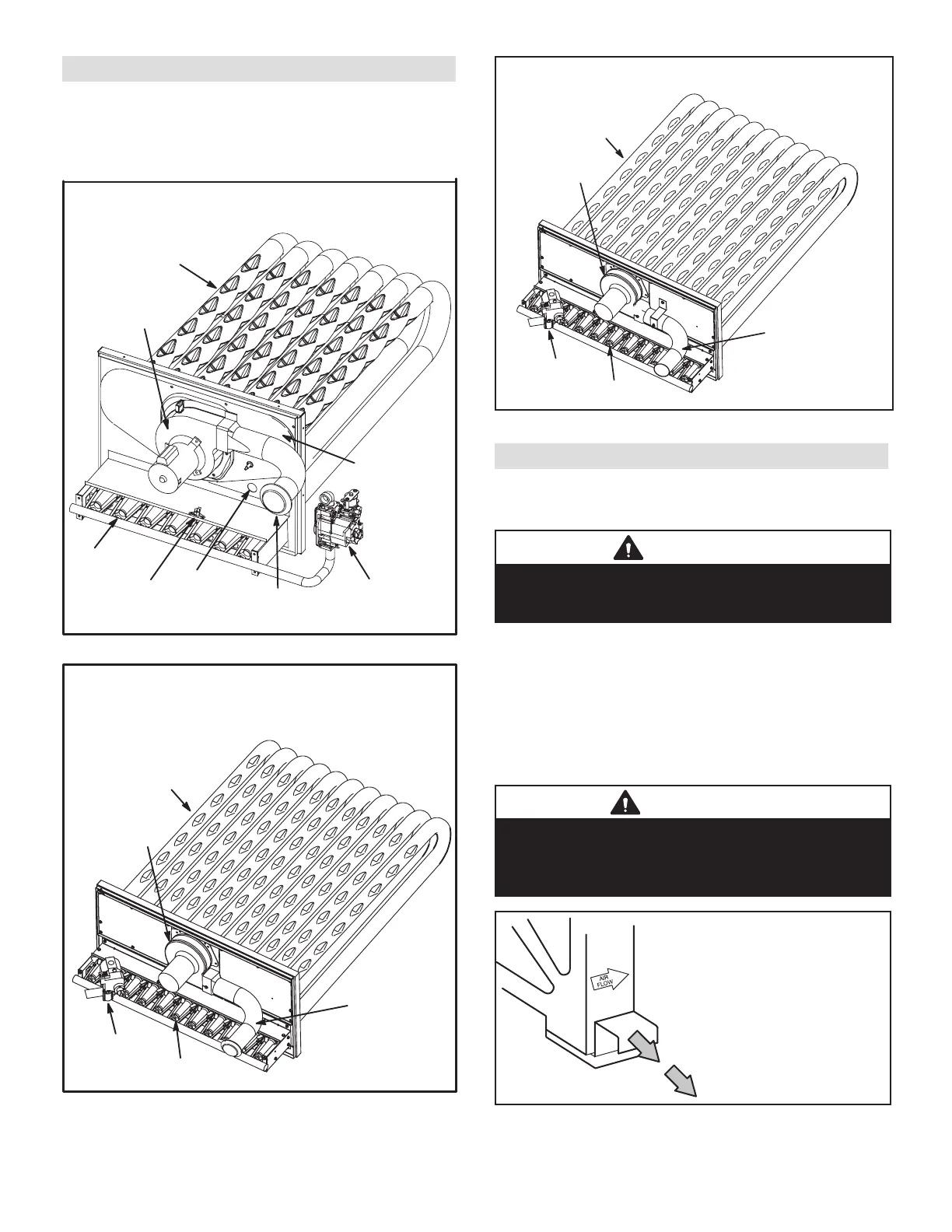

Servicing Filter

Units are equipped with lters as shown in Table 1.

Filters should be checked monthly and replaced when

necessary. Take note of air ow direction marking on

lter frame when reinstalling lters. See Figure 8.

NOTE - Replace factory-installed lters within 30 days

of initial unit start-up. Refer to local codes or appropriate

jurisdiction for approved lters.

WARNING

Units are shipped from the factory with temporary lters.

Replace lters before building is occupied. Damage to

unit could result if lters are not replaced with approved

lters. Refer to appropriate codes.

REMOVE FILTERS

PULL TO REMOVE

FILTERS

FIGURE 8

Loading...

Loading...