Page 23

Low temperature solvent cement is recommended during

cooler weather. Metal or plastic strapping may be used for

vent pipe hangers. Uniformly apply a liberal coat of PVC

primer for PVC or use a clean dry cloth for ABS to clean in

side socket surface of fitting and male end of pipe to depth

of fitting socket.

Canadian Applications Only - Pipe, fittings, primer and

solvent cement used to vent (exhaust) this appliance must

be certified to ULC S636 and supplied by a single

manufacturer as part of an approved vent (exhaust) sys

tem. In addition, the first three feet of vent pipe from the fur

nace flue collar must be accessible for inspection.

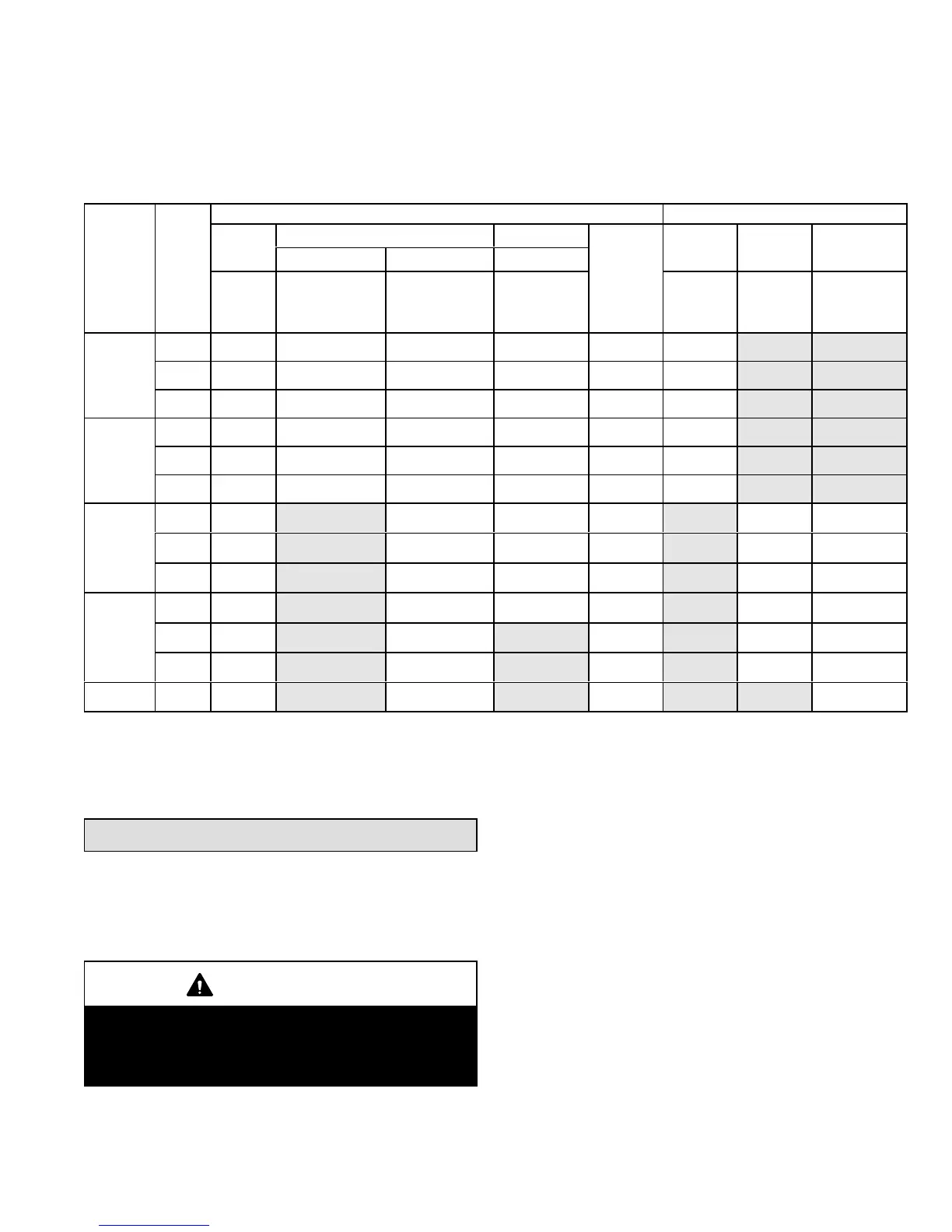

TABLE 12

OUTDOOR TERMINATION USAGE*

Input Size

Vent

Pipe

Dia. in.

STANDARD KITS CONCENTRIC KITS

Flush

Mount

Kit

Wall Kit Wall Ring Kit

Field

Fabricated

1-1/2 inch 2 inch 3 inch

2 inch 3 inch 2 inch

51W11

(US)

51W12

(CA)

22G44 (US)

4

30G28 (CA)

44J40

(US)

4

81J20 (CA)

15F74

71M80

(US)

4

44W92

(CA)

69M29

(US)

4

44W92

(CA)

60L46 (US)

4

44W93 (CA)

045

2

3

YES YES

1

YES

1

YES

5

YES

2

YES

2-1/2

3

YES YES

1

YES

1

YES

5

YES

2

YES

3

3

YES YES

1

YES

1

YES

5

YES

2

YES

070

2

3

YES YES

1

YES

1

YES

5

YES

2

YES

2-1/2

3

YES YES

1

YES

1

YES

5

YES

2

YES

3

3

YES YES

1

YES

1

YES

5

YES

2

YES

090

2

3

YES YES YES

5

YES YES YES

2-1/2

3

YES YES YES

5

YES YES YES

3

3

YES YES YES

5

YES YES YES

110

2 YES YES YES

5

YES YES YES

2-1/2 YES YES

5

YES YES YES

3 YES YES

5

YES YES YES

135 3 YES

YES

5

YES YES

NOTE - Standard Terminations do not include any vent pipe or elbows external to the structure. Any vent pipe or elbows external to the structure must be included in total vent length

calculations. See vent length tables.

* Kits must be properly installed according to kit instructions.

1

Requires field-provided outdoor 1-1/2” exhaust accelerator.

2

Concentric kits 71M80 and 44W92 include 1-1/2” outdoor accelerator, when uses with 045 and 070 input models.

3

Flush mount kits 51W11 and 51W12 includes 1-1/2 in. outdoor exhaust accelerator, required when used with 045, 070 and 090 input models.

4

Termination kits 30G28, 44W92, 4493 and 81J20 are certified to ULC S636 for use in Canada only.

5

See table 17 for vent accelerator requirements.

Joint Cementing Procedure

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

NOTE - A sheet metal screw may be used to secure the in

take pipe to the connector, if desired. Use a drill or self tap

ping screw to make a pilot hole.

DANGER

DANGER OF EXPLOSION!

Fumes from PVC glue may ignite during system

check. Allow fumes to dissipate for at least 5 minutes

before placing unit into operation.

1 - Measure and cut vent pipe to desired length.

2 - Debur and chamfer end of pipe, removing any ridges

or rough edges. If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in a

leaking joint.

3 - Clean and dry surfaces to be joined.

4 - Test fit joint and mark depth of fitting on outside of

pipe.

5 - Uniformly apply a liberal coat of PVC primer for PVC or

use a clean dry cloth for ABS to clean inside socket

surface of fitting and male end of pipe to depth of fitting

socket.

NOTE - Time is critical at this stage. Do not allow prim

er to dry before applying cement.

Loading...

Loading...