Page 44

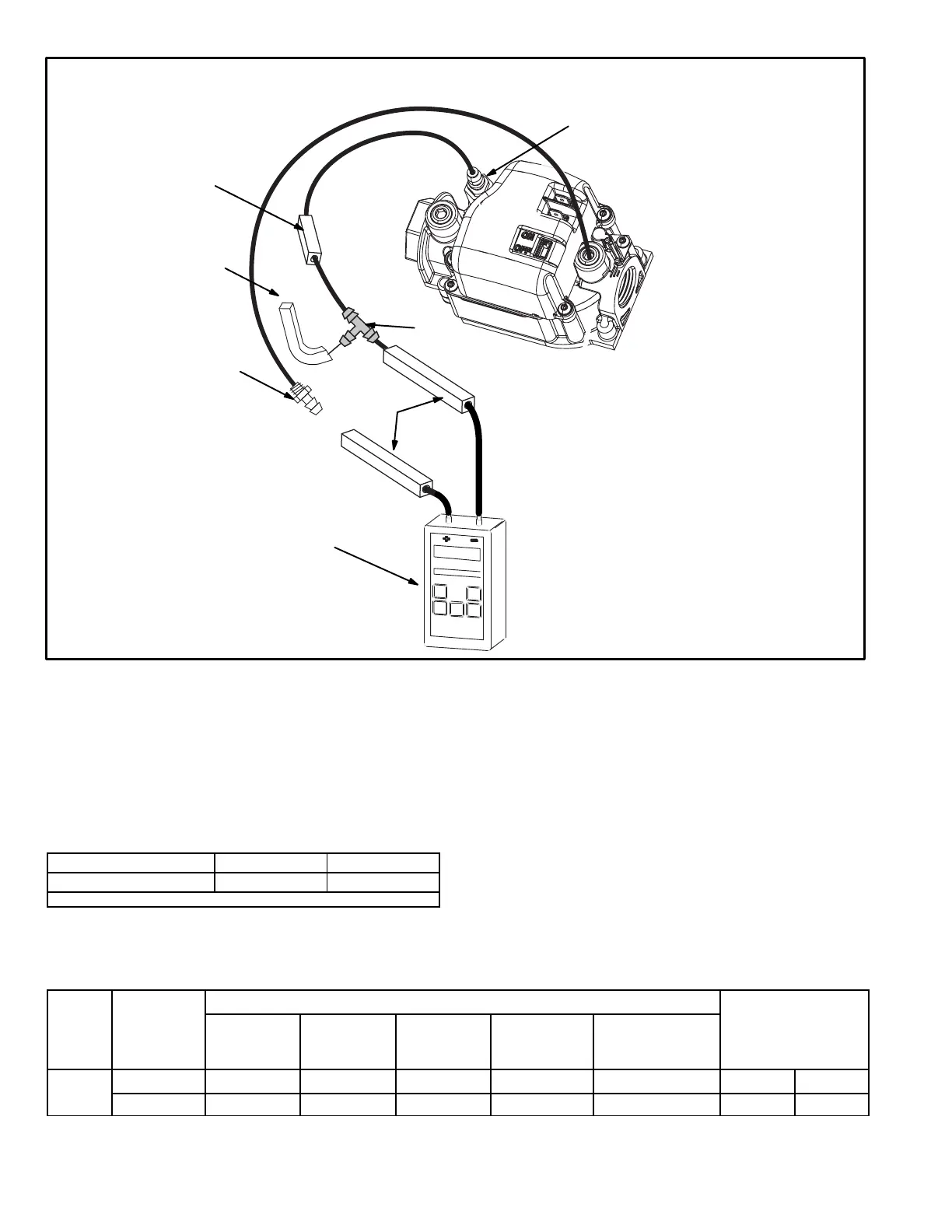

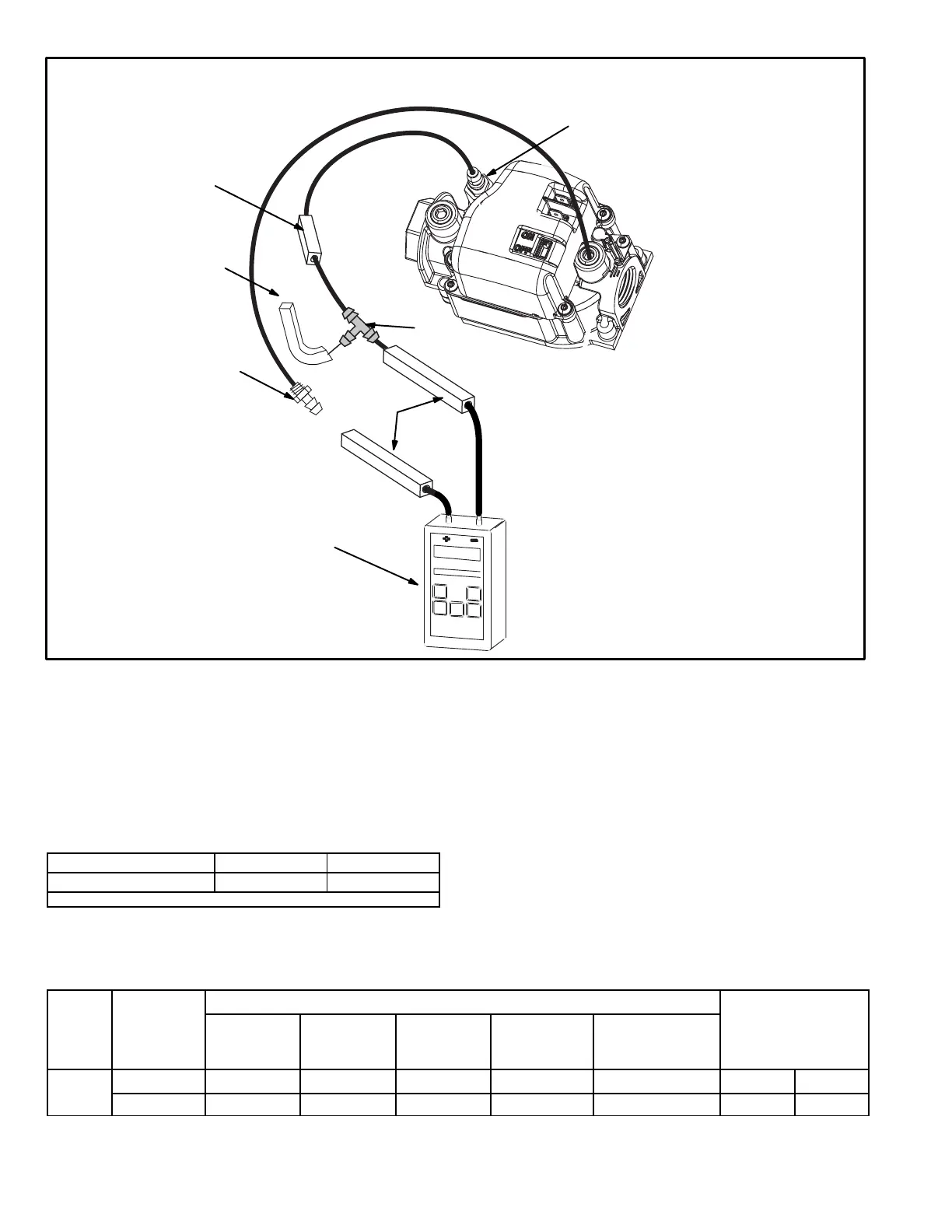

FIGURE 56

(+)

(−)

Gas Valve Regulator

Vent Hose

(to burner box)

2” Long Square Tubing

(remove for manifold adjustment)

Tee

10” Long

Square

Tubing

Measuring Device

Barbed Fitting

Manifold Pressure Outlet

Negative Barbed Fitting

(remove for manifold adjustment)

MANIFOLD PRESSURE CHECK SET UP

E-Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas flow rate before checking com

bustion. Take combustion sample beyond the flue outlet

and compare to the tables below.

TABLE 17

Unit

CO

2

%

For

Nat

CO

2

%

For

LP

All 7.5 - 8.5 8.2 - 9.5

The maximum carbon monoxide reading should not exceed 100 ppm.

F-High Altitude

NOTE - In Canada, certification for installations at eleva

tions over 4500 feet (1372 m) is the jurisdiction of local au

thorities.

Some units installed at altitude of 4501 - 10,000 feet (1373

to 3048 m) may require a pressure switch change which

can be ordered separately and a manifold de-rate. See ta

ble 18 for manifold pressures at all altitudes. Table 19 lists

conversion kit and pressure switch requirements at varying

altitudes.

The combustion air pressure switch is factory-set and re

quires no adjustment.

TABLE 18

Manifold and Supply Line Pressure 0-10,000ft.

ML196

Unit

Gas

Manifold Pressure in. wg.

Supply Line

Pressure

in. w.g.

0 - 10000 ft.

0-4500 ft.

4501-5500

ft.

5501-6500

ft.

6501 - 7500ft. 7501 - 10000ft.

All

Sizes

Natural 3.5 3.3 3.2 3.1 3.5 4.5 13.0

LP/propane 10.0 9.4 9.1 8.9 10.0 11.0 13.0

NOTE - A natural to L.P. propane gas changeover kit is necessary to convert this unit. Refer to the changeover kit installation instruction for the conversion

procedure.

Loading...

Loading...