8

Torque Requirements for Caps and

Fasteners

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. “Table 1. Torque

Requirements” provides torque values for fasteners.

IMPORTANT

Only use Allen wrenches of sufcient hardness (50Rc -

Rockwell scale minimum). Fully insert the wrench into

the valve stem recess.

Service valve stems are factory-torqued from 9 ft.-lbs.

(12 N*m) for small valves, to 25 ft.-lbs. (34 N) for large

valves) to prevent refrigerant loss during shipping and

handling. Using an Allen wrench rated at less than 50Rc

risks rounding or breaking off the wrench, or stripping

the valve stem recess.

See the Lennox Service and Application Notes C-08-1

for further details and information.

Table 1. Torque Requirements

Parts

Recommended Torque

U.S. Newton-Meter- N

Service valve cap 8 ft.-lb. 11

Sheet metal screws 16 in.-lb. 2

Machine screws #10 27 in.-lb. 3

Compressor bolts 7 ft.-lb. 10

Gauge port seal cap 8 ft.-lb. 11

Indoor Unit Installation

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

Unit Placement Considerations

AVOID

Do not install the unit in the following locations:

• Areas exposed to petrochemicals or petrochemical

products

• Areas exposed to salt or other corrosive materials or

caustic gases

• Areas exposed to extreme voltage variations (such as

factories

• Tightly enclosed areas that may impede service of the

unit

• Areas exposed to fossil fuels (such as oil or gas in

kitchens)

• Areas exposed to strong electromagnetic forces

• Areas exposed to acids or alkaline detergents

DO

• Place the unit so that it is not exposed to direct sunlight

• Ensure the structural ceiling can support the weight of

the unit

• Select a location where condensate line will have the

shortest run to a suitable drain per local codes

• Allow sufcient space around unit for proper operation

and maintenance

• Install unit a minimum of 3 feet (1m) away from any

antenna, power cord (line) radio, telephone, security

system, or intercom. Electrical interference and radio

frequencies from any of these sources may affect op-

eration

• Be sure to instruct customers how to properly operate

the unit (especially maintenance of air lter, and oper-

ation procedure) by having them carry out operations

themselves while looking at the manual provided with

the controller

Installation

1. Make sure that the structural ceiling or slab is able

to support the weight of the indoor unit. It may be

necessary to add extra support.

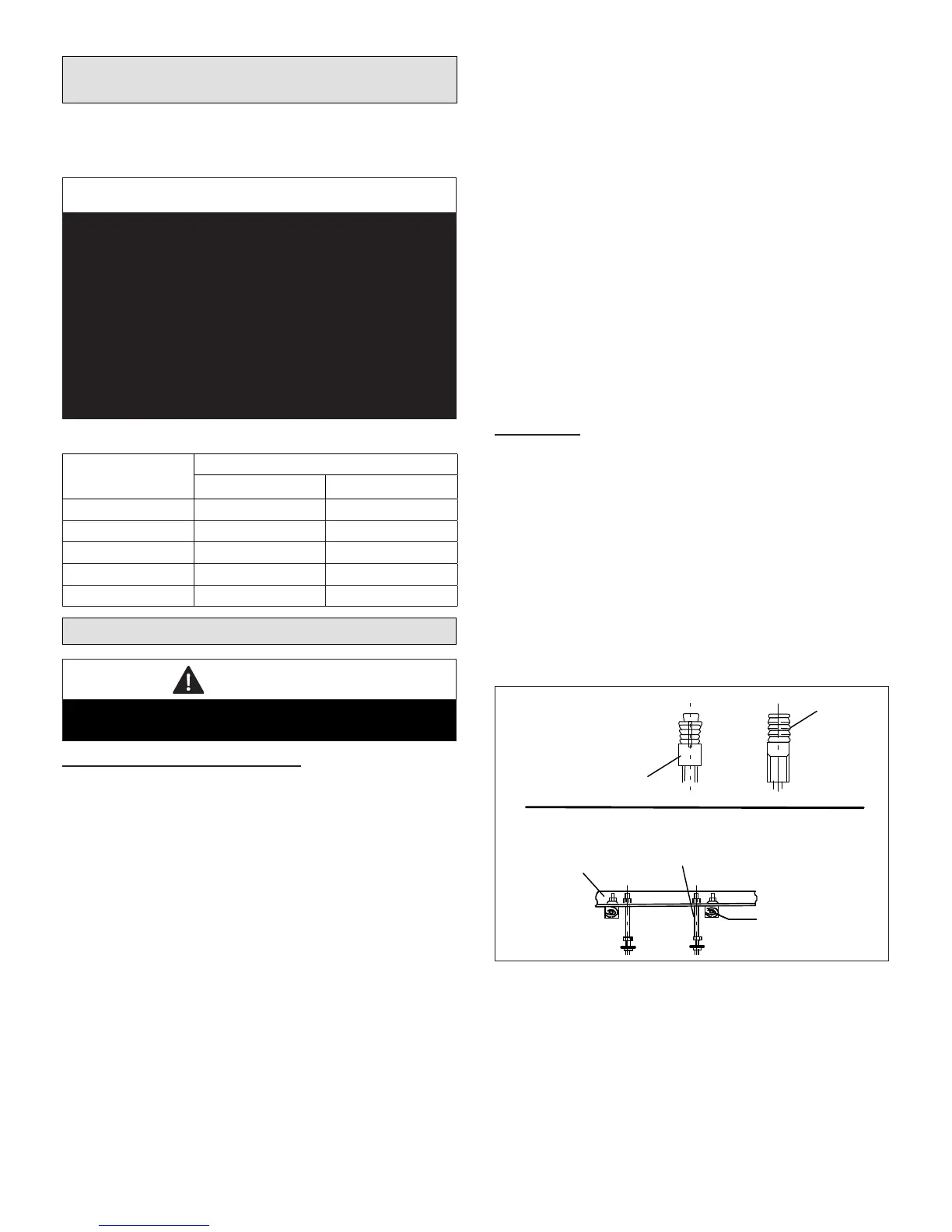

2. Install suspension rods in the structural

ceiling or concrete slab in a suitable location.

If the structural ceiling is constructed of concrete, install

anchors to accept four ⅜” threaded rods to suspend

the indoor unit. If the structural ceiling includes

wooden joists, use angle iron or Unistrut channel xed

securely in place to accept the ⅜” threaded rods.

NOTE: Threaded rod is the ONLY acceptable method of

suspending the unit; do not use chains or straps.

See “Figure 6. Suspending Methods”.

ANGLE IRON

BOLTED IN

PLACE ACROSS

WOODEN JOISTS

WOODEN JOIST

⅜” THREADED

ROD

ANGLE IRON

ACROSS

WOODEN JOISTS

ANCHOR

CONCRETE CEILING

USING ANCHORS

⅜” THREADED

ROD

Figure 6. Suspending Methods

3. Slide one nut and one washer onto each threaded rod.

Use electrical tape to keep the washer from failing

off. Position the nuts slightly above the nal resting

place of the four suspension brackets. See”Figure 7.

Suspending Hardware”

Loading...

Loading...