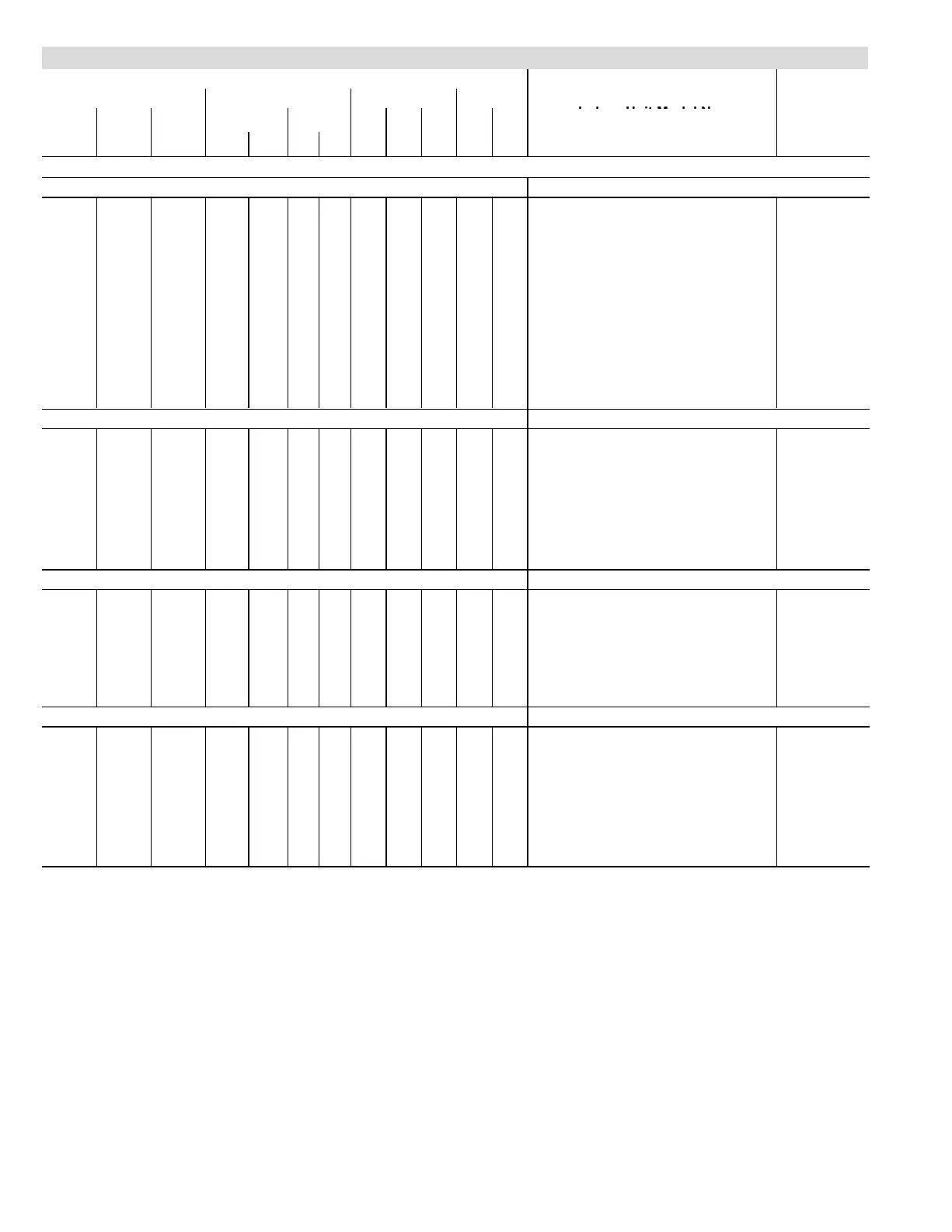

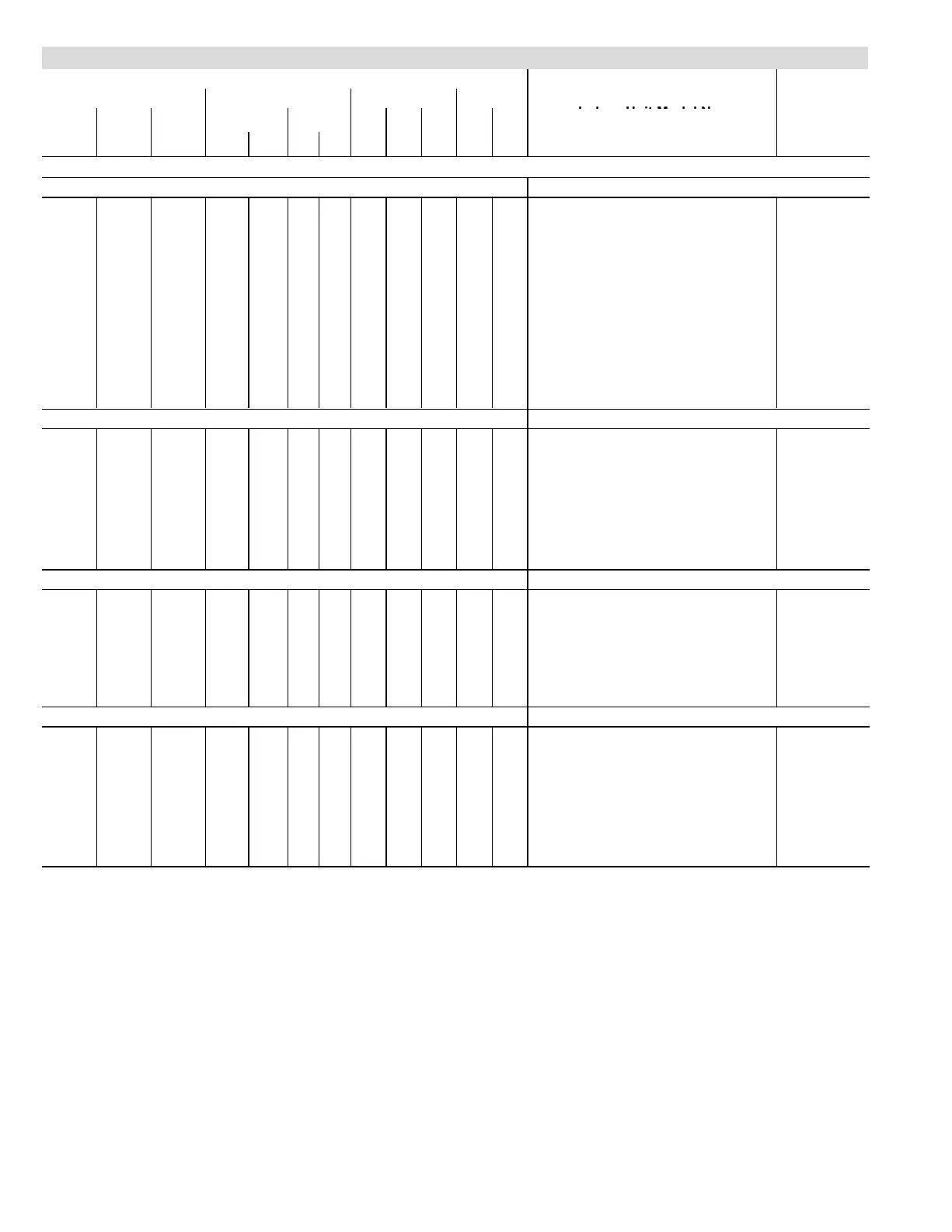

TP − 3 to 5 Ton R−22 Heat Pump Outdoor Units / Page 10

ARI RATINGS

1

ARI Standard 210/240 Ratings

Capacity − Btuh Efficiency Total Watts COP

High

Low

HSPF

Hi

h Low Hi

h Low

Indoor Unit Model No.

Device

oo

ng

Temp.

Heating

Temp.

Heating

SEER EER IV V

oo

Heat

Heat

Heat

Heat

TPA036S2 3 TON

Air Handlers Air Handlers

34,400 33,600 20,800 13.00 11.00 7.70 6.75 3150 2825 2695 3.48 2.26

3

CB30M−41 (Multi−Position) Factory TXV

34,400 33,600 20,800 13.00 11.00 7.70 6.70 3155 2830 2710 3.48 2.24

3

CB30U−41/46 (Up−Flow) Factory TXV

34,400 34,000 21,200 12.20 10.40 7.70 6.70 3245 2925 2755 3.40 2.26

3,6

CB29M−46 (Multi−Position) Factory TXV

34,600 33,600 20,800 13.00 11.00 7.70 6.80 3130 2790 2670 3.52 2.28

3

CB30M−46 (Multi−Position) Factory TXV

34,600 34,200 21,600 12.00 10.30 7.50 6.60 3350 3045 2840 3.24 2.22

3

CB29M−51 (Multi−Position) Factory TXV

34,800 33,400 20,800 13.00 11.00 7.70 6.80 3125 2765 2650 3.54 2.30

4

CB31MV−41 (Multi−Position) Factory TXV

34,800 33,200 20,600 13.50 11.00 7.70 6.70 3165 2705 2570 3.60 2.34

4

CB27UH−036 (Up−Flow / Horizontal) Factory TXV

35,200 33,800 21,000 13.00 11.00 7.70 7.10 3165 2760 2515 3.58 2.44

5

CB26UH−036 (Up−Flow/Horiz.) Factory TXV

36,400 33,000 20,400 14.00 12.00 7.70 6.70 3035 2700 2505 3.58 2.38

4

CB27UH−042 (Up−Flow / Horizontal)

2

56J19

Up−Flow Indoor Coils + Furnaces Up−Flow Coils + Furnaces

34,200 33,200 20,600 13.00 11.00 7.70 6.80 3080 2875 2610 3.38 2.32 C33−36B

4

G60UHV−36B−090

2

56J19

34,200 33,200 20,600 13.00 11.00 7.70 6.75 3065 2885 2615 3.38 2.30 C33−36C

4

G61MPV−36C−090

2

56J19

34,200 33,200 20,600 13.00 11.00 7.70 6.80 3080 2875 2610 3.38 2.32 C33−42B

4

G60UHV−36B−090

2

56J19

34,400 33,200 20,800 13.00 11.00 7.70 6.80 3100 2865 2615 3.40 2.32 C33−36C

4

G61MPV−60C−090

2

56J19

34,600 33,200 20,600 13.00 11.00 7.70 6.85 3085 2840 2590 3.42 2.32 C33−36C

4

G60UHV−60C−110

2

56J19

34,600 33,200 20,800 13.00 11.00 7.70 6.80 3095 2850 2605 3.42 2.34 C33−36C

4

G61MPV−60C−110

2

56J19

Down−Flow Indoor Coils + Furnaces Down−Flow Coils + Furnaces

34,600 33,400 20,800 13.00 11.00 8.20 7.20 3060 2675 2425 3.66 2.52 CR33−30/36B−F

4

G60DFV−36B−090

2

56J19

34,600 33,400 20,800 13.00 11.00 8.20 7.20 3075 2695 2435 3.64 2.50 CR33−30/36C−F

4

G61MPV−36C−090

2

56J19

34,600 33,200 20,600 13.00 11.00 7.70 7.05 3060 2760 2495 3.52 2.42 CR33−48B−F

4

G60DFV−36B−090

2

56J19

34,800 33,600 20,800 13.00 11.00 8.20 7.20 3105 2680 2440 3.68 2.50 CR33−30/36C−F

4

G61MPV−60C−090

2

56J19

35,000 33,600 20,800 13.00 11.00 8.20 7.25 3100 2665 2430 3.70 2.50 CR33−30/36C−F

4

G61MPV−60C−110

2

56J19

Horizontal Indoor Coils + Furnaces Horizontal Coils + Furnaces

34,000 33,200 20,800 13.00 11.00 7.70 7.00 3075 2785 2510 3.50 2.42 CH23−41

4

G60UHV−36B−090

2

56J19

34,000 33,200 20,800 13.00 11.00 7.70 7.00 3065 2795 2510 3.48 2.42 CH23−41

4

G61MPV−36C−090

2

56J19

34,400 33,400 20,800 13.00 11.00 7.70 7.05 3090 2765 2505 3.54 2.44 CH23−41

4

G61MPV−60C−110

2

56J19

34,600 33,200 20,600 13.00 11.00 7.70 6.80 3075 2835 2625 3.44 2.30 CH33−36C−2F

4

G61MPV−36C−090

2

56J19

34,800 33,400 20,800 13.00 11.00 7.70 6.80 3100 2810 2625 3.48 2.32 CH33−36C−2F

4

G61MPV−60C−090

2

56J19

35,000 33,400 20,800 13.00 11.00 7.70 6.85 3100 2800 2615 3.50 2.32 CH33−36C−2F

4

G61MPV−60C−110

2

56J19

NOTE − These are the only approved system match−ups. For other matches, contact the Lennox Applications Department.

NOTE − Ratings for C33 coils include all cased and uncased coils.

NOTE − When used with gas furnaces, a dual−fuel control (i.e. FM21) or a control system with dual−fuel capabilities (i.e. Harmony III, LZP−2 or LZP−4) must be used (ordered extra).

1

Certified in accordance with USE certification program which is based on ARI Standard 210/240 with 25 ft. (7.6 m) of connecting refrigerant lines;

Cooling Ratings − 95_F (35_C) outdoor air temperature and 80_F (27_C) db/67_F (19_C) wb entering indoor coil air.

High Temperature Heating Ratings − 47_F (8_C) db/43_F (6_C) wb outdoor air temperature and 70_F (21_C) db entering indoor coil air.

Low Temperature Heating Ratings − 17_F (−8.3_C) db/15_F (−9.4_C) wb outdoor air temperature and 70_F (21_C) db entering indoor coil air.

2

Factory installed expansion valve or RFC on indoor unit MUST be replaced with valve specified (if equipped).

3

Blower must be capable of time−off blower delay. Indoor Blower Off Delay Relay (58M81) is recommend for field installation.

4

Blower control must be set for a time−off blower delay.

5

Most popular air handler combination.

Loading...

Loading...