15

8. After refrigerant piping has been installed and checked

for leaks, apply insulation over all fl ared connections.

See Figure 20.

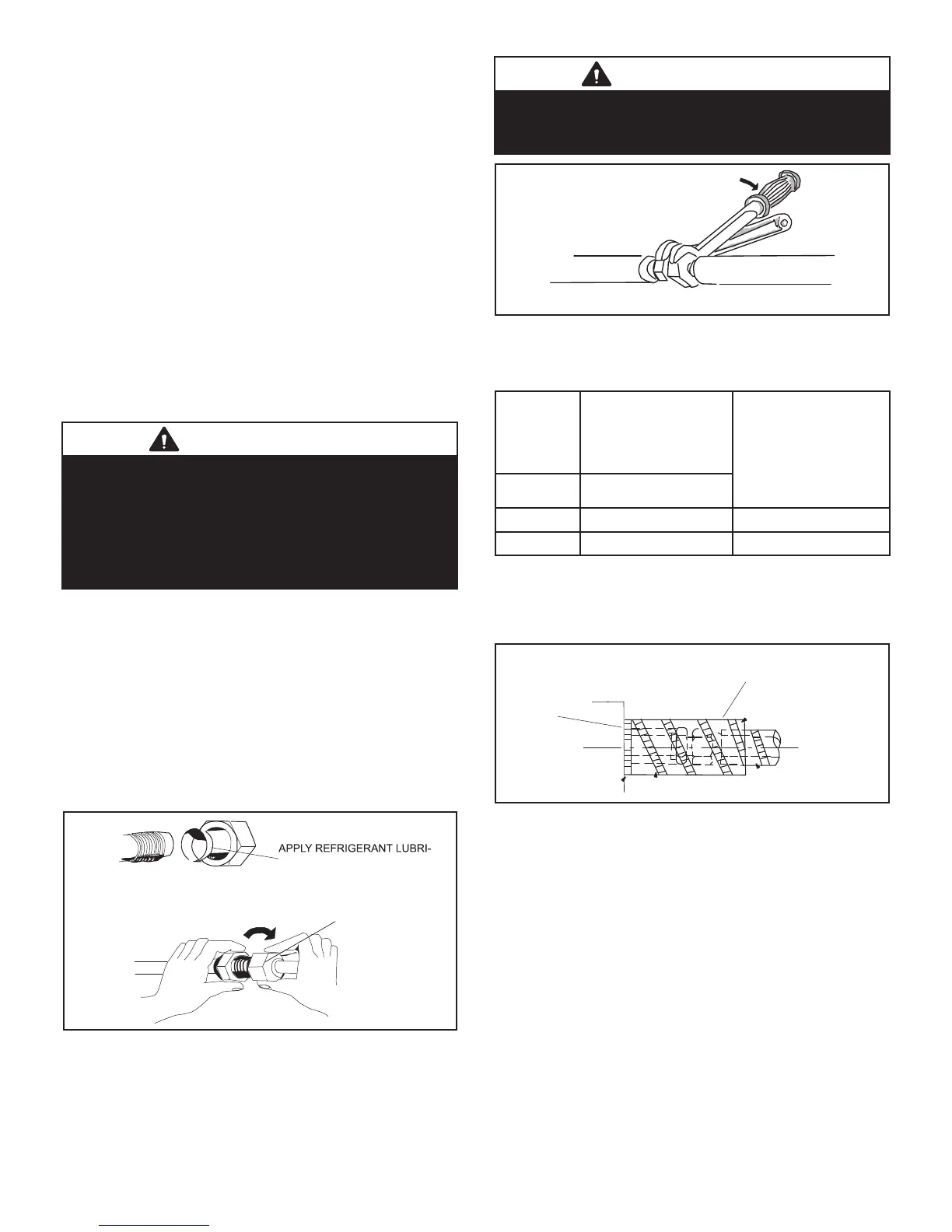

Outside

Diameter

Recommended

Torque

No torque wrench

available

Finger tighten and

use an appropriately

sized wrench to turn

an additional:

Inches

3/8” 26 ft.-lb. (35 N-m) 1/2 turn

3/4” 60 ft.-lb. (81 N-m) 1 turn

Table 2. Flare Nut Torque Recommendations

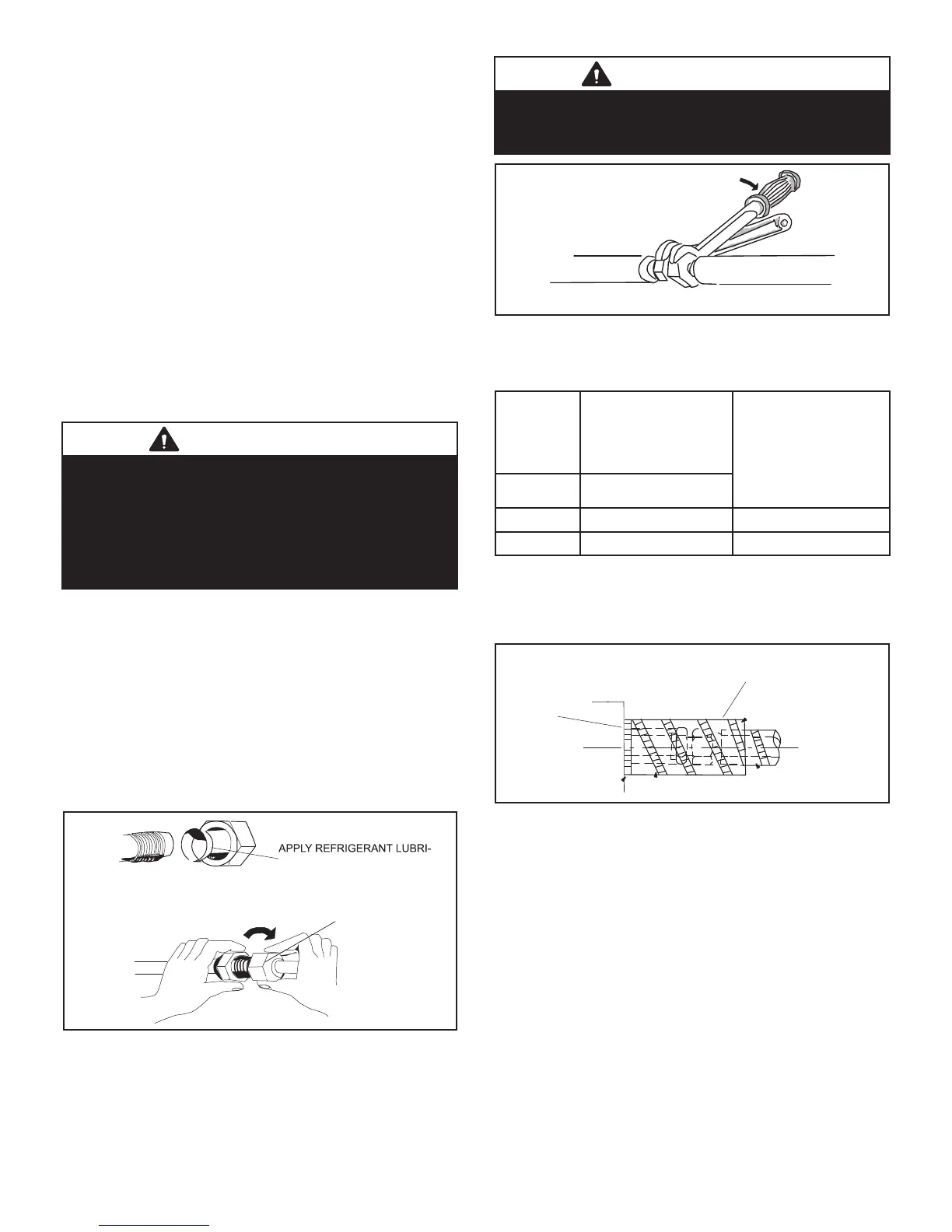

Figure 20. Insulate Flared Connections

UNIT

BASE

INSULATE ALL FLARED CONNECTIONS

TO PREVENT CONDENSATION

A

B

CANT ON THE OUTSIDE OF

THE FLARE

MALE FLARE

CONNECTION

Figure 18. Making Connections

(Male to Female Connection)

Figure 19. Tighten Flare Nut

6. Once snug, continue another half-turn on each

nut which should create a leak-free joint. A torque

wrench may be used to tighten fl are nuts using table

2 recommendations. See Figure 19. Do not over-

tighten a fl ared joint. Flared connections should

always be accessible and must be insulated to

prevent condensation.

7. Branch pipe connections may be brazed. It is

necessary to purge the pipes with nitrogen during

brazing to avoid oxidation which may block the

refrigerant piping.

IMPORTANT

The compressor in this unit contains PVE

oil (Polyvinylether). PVE oil is formulated for

hydrofl uorocarbon (HFC) refrigerants, such as R-

410a, which this system contains. While it may have

some miscibility properties with mineral-based oil

and POE oil (Polyolester), it is not recommended to

mix PVE oil with any other type of refrigerant oil.

IMPORTANT

Always use two wrenches when tightening fl are

nuts to avoid twisting refrigerant piping. DO

NOT over-tighten fl are nuts.

NOTE - Always slide a fl are nut onto the fi eld-provided

refrigerant piping before fl aring the lines.

1. The seal on the unit refrigerant piping connections

should remain in place until the last possible moment.

This will prevent dust or water from getting into the

refrigerant piping before it is connected.

2. Remove the fl are nuts from the connections on the

unit and discard the seal from each of the piping

connections.

3. Slide the fl are nuts onto the ends of the fi eld-provided

refrigerant piping before using a suitable fl aring tool to

fl are the end of the copper pipe.

4. Apply recommended R-410A refrigerant lubricant to

the outside of the fl ared refrigerant lines (Figure 18-

A).

5. Align the threaded connections with the fl ared

refrigerant lines. Tighten the fl are nuts lightly at fi rst to

obtain a smooth match (Figure 18-B).

To Outdoor unit

To Indoor Unit

Backup

Wrench

Torque

Wrench

Loading...

Loading...