9

Refrigerant Piping Connections

Field piping consists of two copper lines connected to the

indoor unit. Table 2 lists the connection sizes at the indoor

unit. Both lines must be individually insulated.

Size (Btuh) Liquid Line Vapor Line

VVCA018-054 3/8” 5/8”

Table 2. Refrigerant Piping Connections

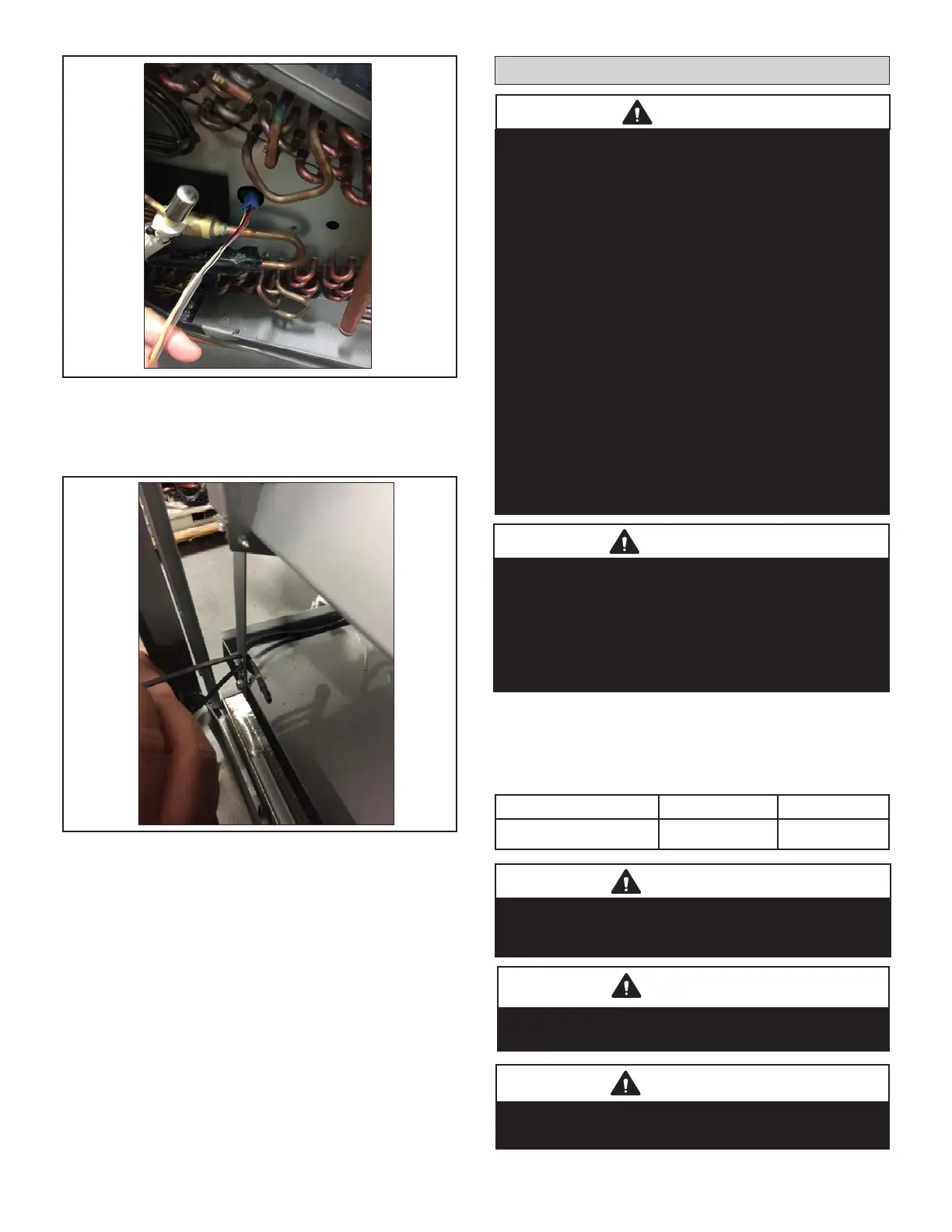

Figure 10. Relocate T-1 Sensor

16. Relocate T-1 Sensor to be downstream of the coil to

sense room air temperature.

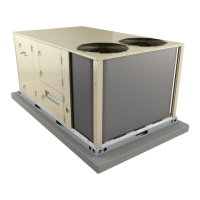

Figure 9. Route Wiring Harness Through Coil and

Into Electrical Compartment

17. Secure T-1 sensor to “top of coil” brace.

18. Re-secure the wiring harness using clips and wire

ties. Do not pinch or bind wires.

19. Reconnect the T2 and T2B sensors.

20. Reconnect the wire harness plug inside of electrical

control box.

21. Turn the coil compartment cover 180° and reattach to

the unit cabinet.

22. Reattach the blower compartment panel.

IMPORTANT

The compressor in the unit this air handler is matched

with contains PVE oil (Polyvinyl ether). PVE oil is

formulated for hydrouorocarbon (HFC) refrigerants,

such as R410A, which this system contains. While it may

have some miscibility properties with mineral-based oil

and POE oil (Polyolester), it is not recommended to mix

PVE oil with any other type of refrigerant oil.

Refrigerant leaks are unlikely; however, if a refrigerant

leak occurs, open a door or windows to dilute the

refrigerant in the room. Turn o the unit and all other

appliances that may cause a spark. Call a licensed

professional HVAC technician (or equivalent) to repair

the leak.

Use only R410A refrigerant to charge this system. Use

of other refrigerant or gas will damage the equipment.

Do not allow air or other contaminants to enter system

during installation of refrigerant piping. Contaminants

will result in lower system capacity and abnormally high

operating pressures and may result in system failure or

explosion.

Insulate all refrigerant piping.

Refrigerant pipes may be very hot during unit operation.

Do not allow contact between wiring and bare copper

pipes.

After refrigerant piping connections have been

completed, check the system for leaks per commissioning

instructions.

WARNING

IMPORTANT

Always use two wrenches when tightening are nuts to

avoid twisting refrigerant piping. DO NOT over-tighten

are nuts.

IMPORTANT

Flared connections should always be accessible and

must be insulated to prevent condensation.

IMPORTANT

Support ALL piping within 12 in. (305 mm) of any

mechanical tting such as a ared connection.

Loading...

Loading...