Page 5

B − Two−Stage Scroll Compressor (B1)

CAUTION

In order to avoid injury, take precaution when

lifting heavy objects.

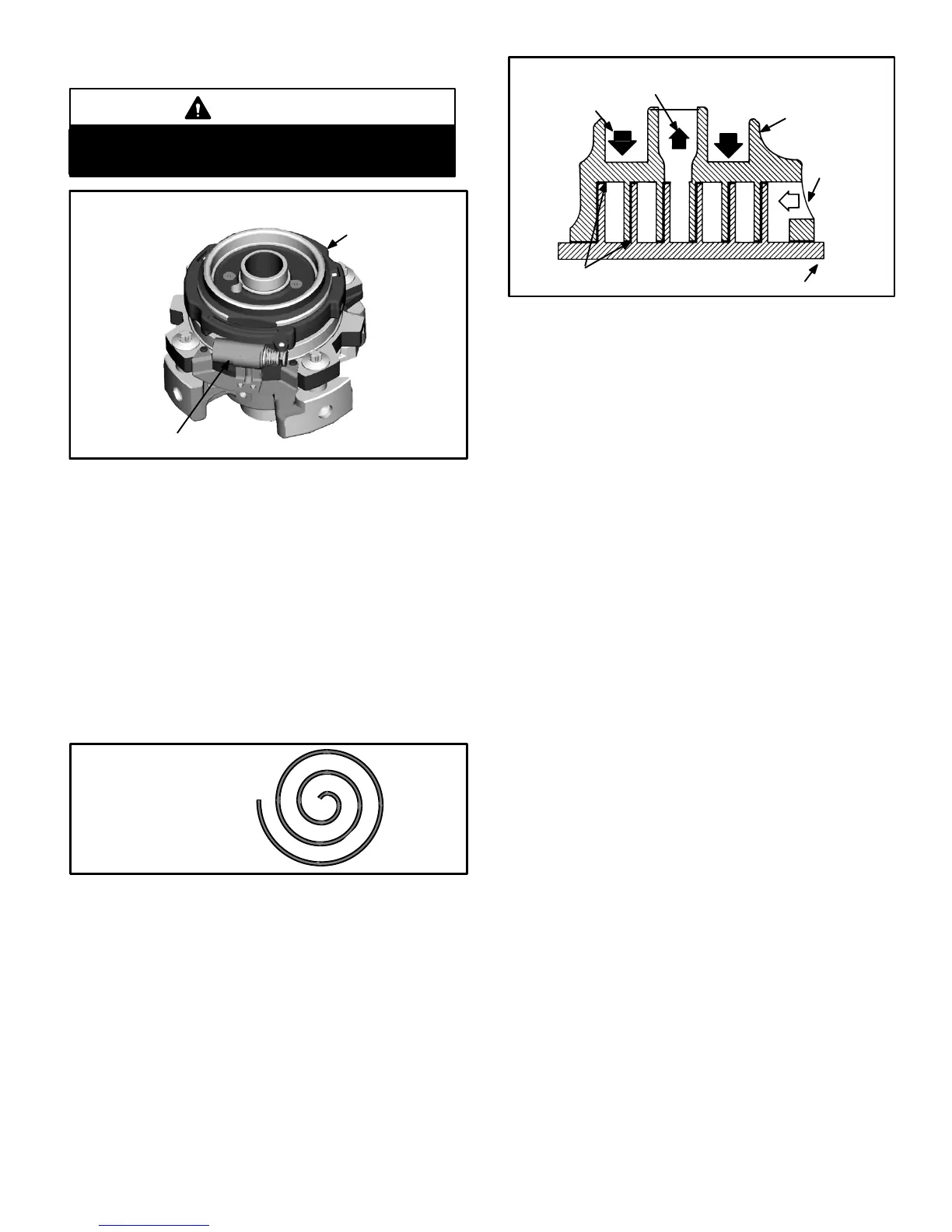

FIGURE 1

TWO−STAGE MODULATED SCROLL

solenoid actuator coil

slider ring

The scroll compressor design is simple, efficient and re-

quires few moving parts. A cutaway diagram of the scroll

compressor is shown in figure 1.The scrolls are located in

the top of the compressor can and the motor is located just

below. The oil level is immediately below the motor.

The scroll is a simple compression concept centered around

the unique spiral shape of the scroll and its inherent proper-

ties. Figure 2 shows the basic scroll form. Two identical

scrolls are mated together forming concentric spiral shapes

(figure 3 ). One scroll remains stationary, while the other is

allowed to orbit" (figure 4). Note that the orbiting scroll does

not rotate or turn but merely orbits" the stationary scroll.

FIGURE 2

SCROLL FORM

FIGURE 3

STATIONARY

SCROLL

ORBITING SCROLL

DISCHARGE

SUCTION

CROSS−SECTION OF SCROLLS

TIPS SEALED BY

DISCHARGE PRESSURE

DISCHARGE

PRESSURE

The counterclockwise orbiting scroll draws gas into the outer

crescent shaped gas pocket created by the two scrolls (figure

4 − 1). The centrifugal action of the orbiting scroll seals off the

flanks of the scrolls (figure 4 − 2). As the orbiting motion con-

tinues, the gas is forced toward the center of the scroll and the

gas pocket becomes compressed (figure 4 −3). When the

compressed gas reaches the center, it is discharged vertical-

ly into a chamber and discharge port in the top of the com-

pressor (figure1). The discharge pressure forcing down on

the top scroll helps seal off the upper and lower edges (tips) of

the scrolls (figure 3 ). During a single orbit, several pockets of

gas are compressed simultaneously providing smooth con-

tinuous compression.

The scroll compressor is tolerant to the effects of liquid re-

turn. If liquid enters the scrolls, the orbiting scroll is allowed

to separate from the stationary scroll. The liquid is worked

toward the center of the scroll and is discharged. If the com-

pressor is replaced, conventional Lennox cleanup practices

must be used.

Due to its efficiency, the scroll compressor is capable of

drawing a much deeper vacuum than reciprocating com-

pressors. Deep vacuum operation can cause internal fusite

arcing resulting in damaged internal parts and will result in

compressor failure. This type of damage can be detected

and will result in denial of warranty claims. The scroll com-

pressor can be used to pump down refrigerant as long as

the pressure is not reduced below 7 psig.

The scroll compressors in all XC16 model units are de-

signed for use with R410A refrigerant and operation at high

pressures. Compressors are shipped from the factory with

3MA (32MMMA) P.O.E. oil. See electrical section in this

manual for compressor specifications.

NOTE − During operation, the head of a scroll compressor

may be hot since it is in constant contact with discharge

gas.

Loading...

Loading...