Page 6

TWO−STAGE OPERATION

NOTE − During operation, the head of a scroll compressor

may be hot since it is in constant contact with discharge

gas.

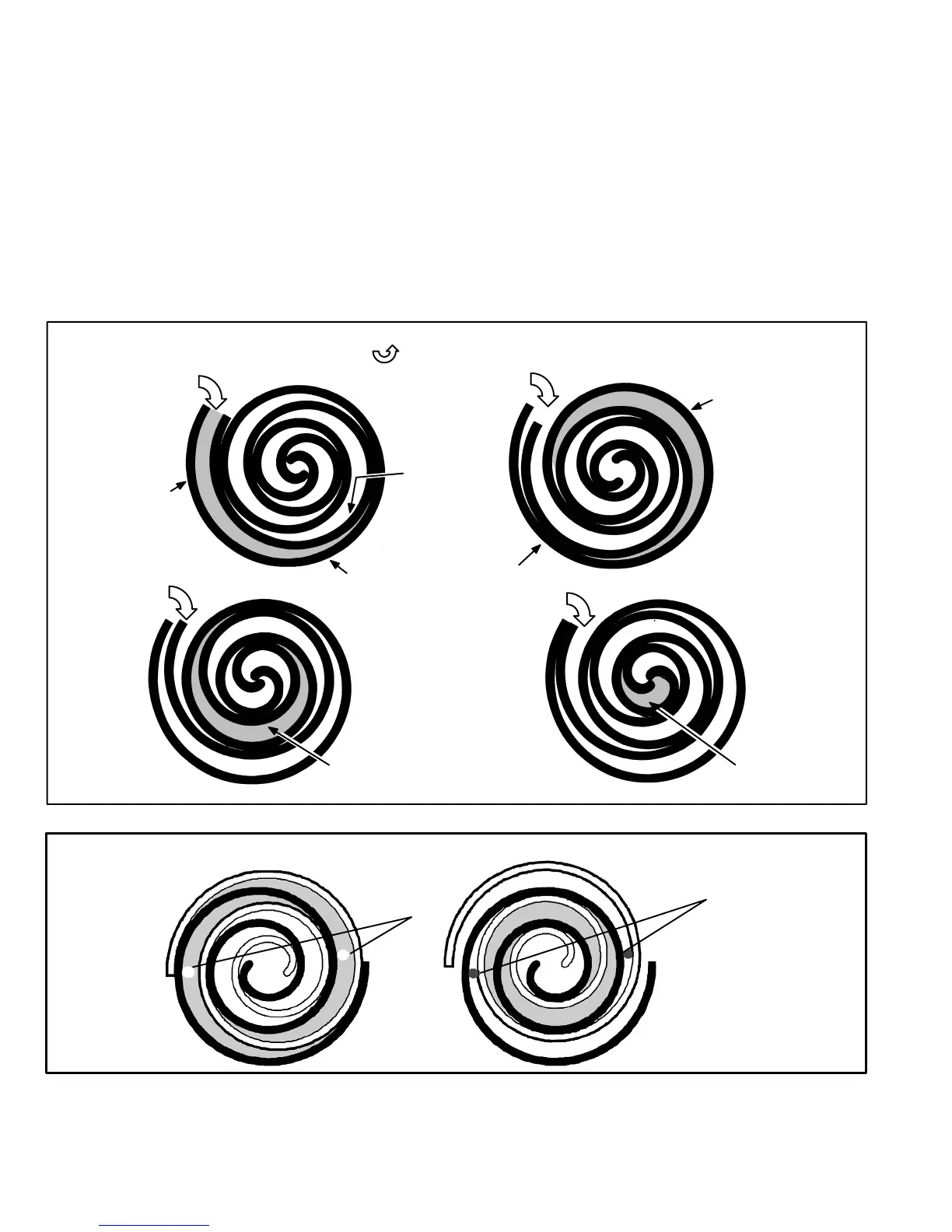

The two−stage scroll compressor operates like any standard

scroll compressor with the exception the two−stage com-

pressor modulates between first stage (low capacity

approximately 67%) and second stage (high capacity).

Modulation occurs when gas is bypassed through bypass

ports (figure 5 bypass ports open) in the first suction pocket.

This bypassing of gas allows the compressor to operate on

first stage (low capacity) if thermostat demand allows. In-

door thermostat setting will determine first or second stage

operation. The compressor will operate on first−stage until

demand is satisfied or the indoor temperature reaches the

thermostat set point calling for second−stage.

Second−stage (high capacity) is achieved by blocking the

bypass ports (figure 5 bypass ports closed) with a slider ring.

The slider ring begins in the open position and is controlled

by a 24VDC internal solenoid. On a Y2 call the internal sole-

noid closes the slider ring, blocking the bypass ports and

bringing the compressor to high capacity. Two−stage modu-

lation can occur during a single thermostat demand as the

motor runs continuously while the compressor modulates

from first−stage to second− stage.

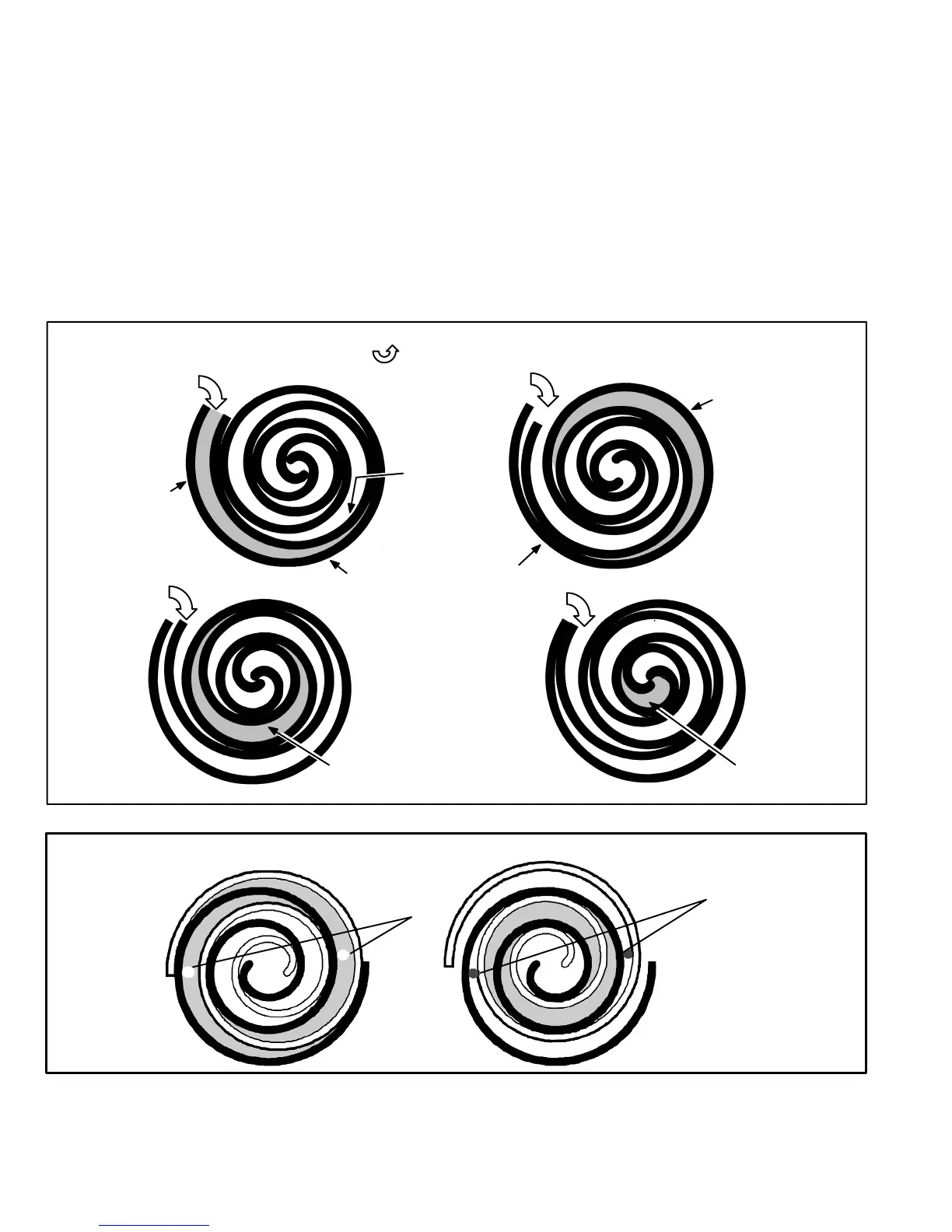

FIGURE 4

SCROLL

HOW A SCROLL WORKS

SUCTION

SUCTION

SUCTION

MOVEMENT OF ORBIT

STATIONARY SCROLL

ORBITING

CRESCENT

SHAPED GAS

POCKET

HIGH

PRESSURE

GAS

DISCHARGE

POCKET

FLANKS

SEALED BY

CENTRIFUGAL

FORCE

12

3

4

SUCTION

INTERMEDIATE

PRESSURE

GAS

SUCTION

POCKET

FIGURE 5

Bypass Ports

Closed

High Capacity

Bypass Ports

Open

67% Capacity

TWO STAGE MODULATION

Loading...

Loading...