Page 33

V- SYSTEMS SERVICE CHECKS

A-Cooling System Service Checks

ZCC units are factory charged and require no further ad-

using the approach method. The approach method com-

pares actual liquid temperature with the outdoor ambient

NOTE-When unit is properly charged discharge line pres-

sures should approximate those in tables 4 through 7.

VI-MAINTENANCE

service technician.

WARNING

Electric shock hazard. Can cause injury or

death. Before attempting to perform any

Unit may have multiple power supplies.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

IMPORTANT

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC’s and HCFC’s) as of July

1, 1992. Approved methods of recovery, recycling

or reclaiming must be followed. Fines and/or

incarceration may be levied for non-compliance.

A-Filters

-

fer to local codes or appropriate jurisdiction for approved

WARNING

Units are shipped from the factory with temporary

NOTE-Filters must be U.L.C. certied or equivalent for

use in Canada.

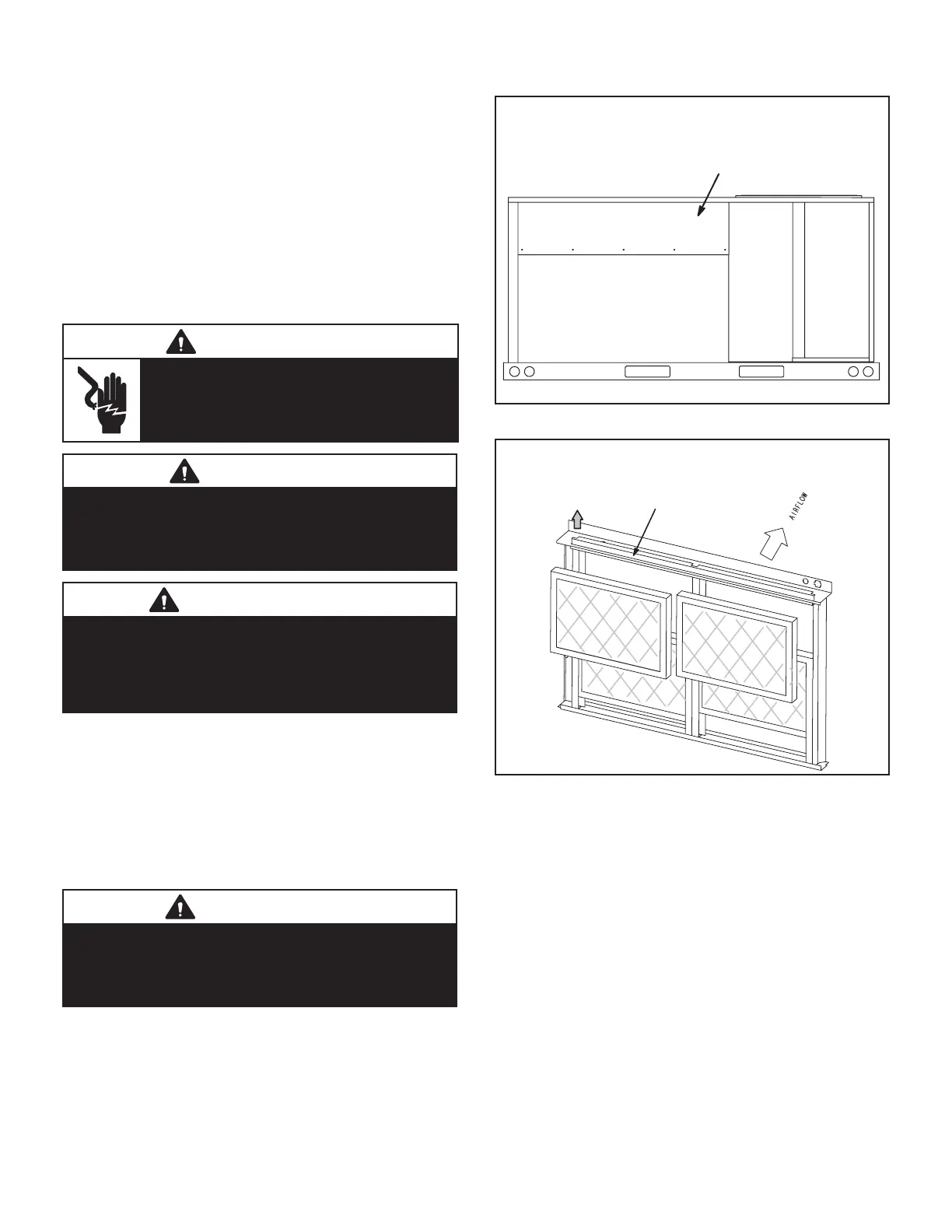

BACK OF UNIT

FILTER ACCESS PANEL

LIFT UP AND PULL

OUT (TOOLLESS)

FIGURE 14

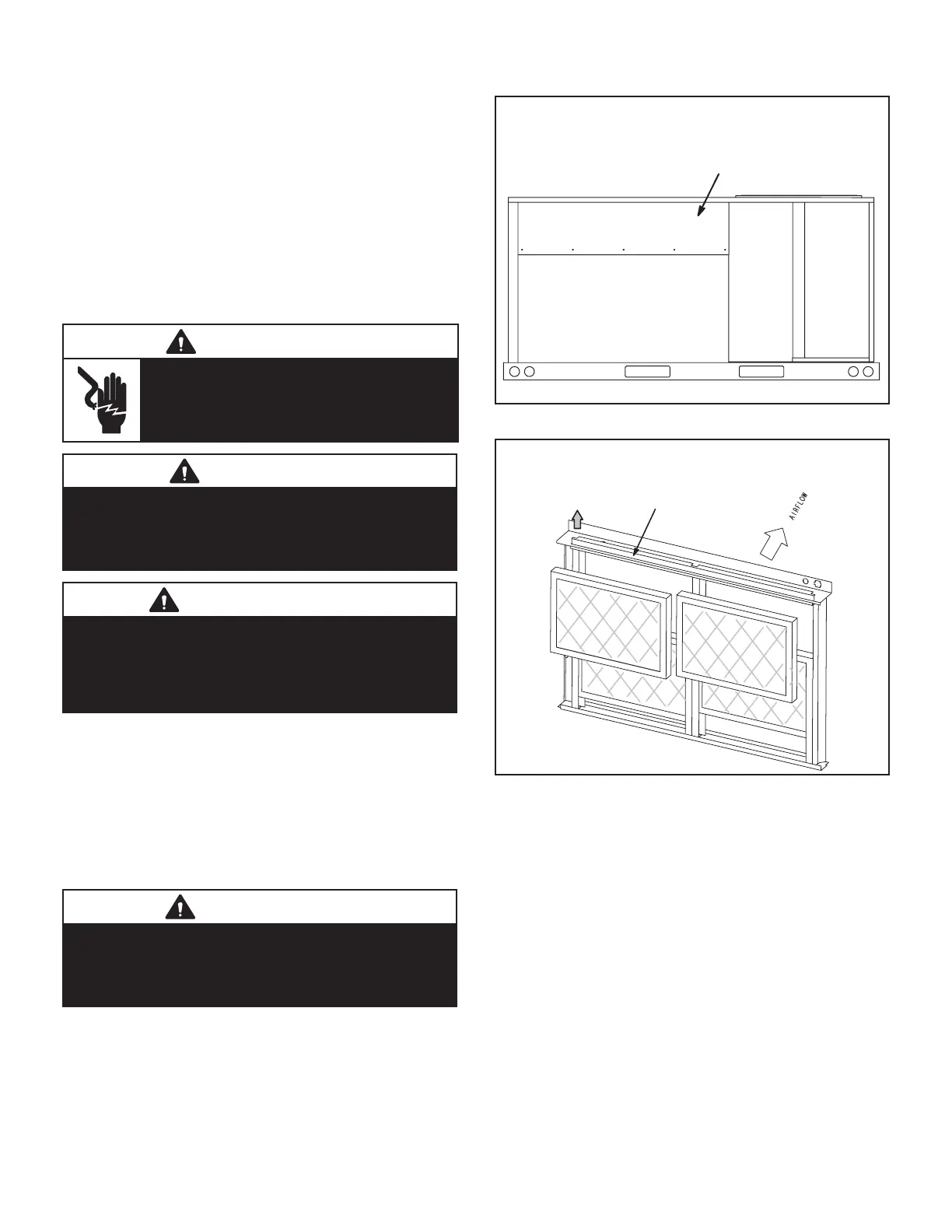

SLIDE FILTER STOP UP

TO REMOVE FILTERS

FIGURE 15

B-Lubrication

All motors are lubricated at the factory. No further lubrica-

tion is required.

C-Evaporator Coil

Inspect and clean coil at beginning of each cooling season.

Clean using mild detergent or commercial coil cleanser.

D-Condenser Coil

Clean condenser coil annually with water and inspect

monthly during the cooling season.

Note - Do not use commercial coil cleaner on the all alu-

minum coil. Using anything other than water could result

in corrosion and/or leaks.

Loading...

Loading...