Mechanical installation

Mounting

Attachment of motors to gearboxes with bearing housing (input design N)

5

30

Lenze • BA 12.0023 • 9.0

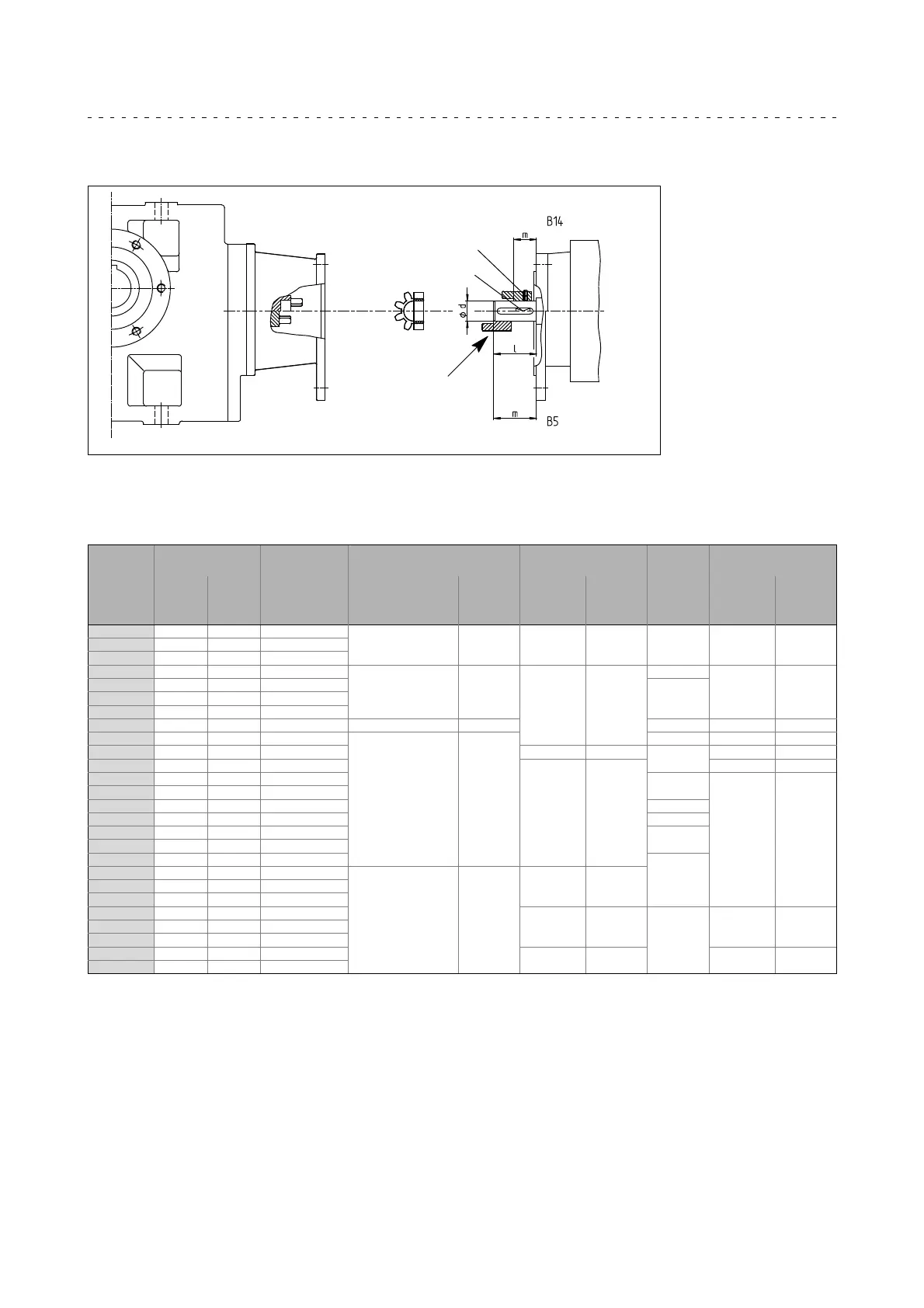

5.3.4 Attachment of motors to gearboxes with bearing housing (input design N)

1

2

K12.0621

Fig. 3 Input side design N

Spider / gear rim 1 Locking screw

Coupling hub 2 Keyway

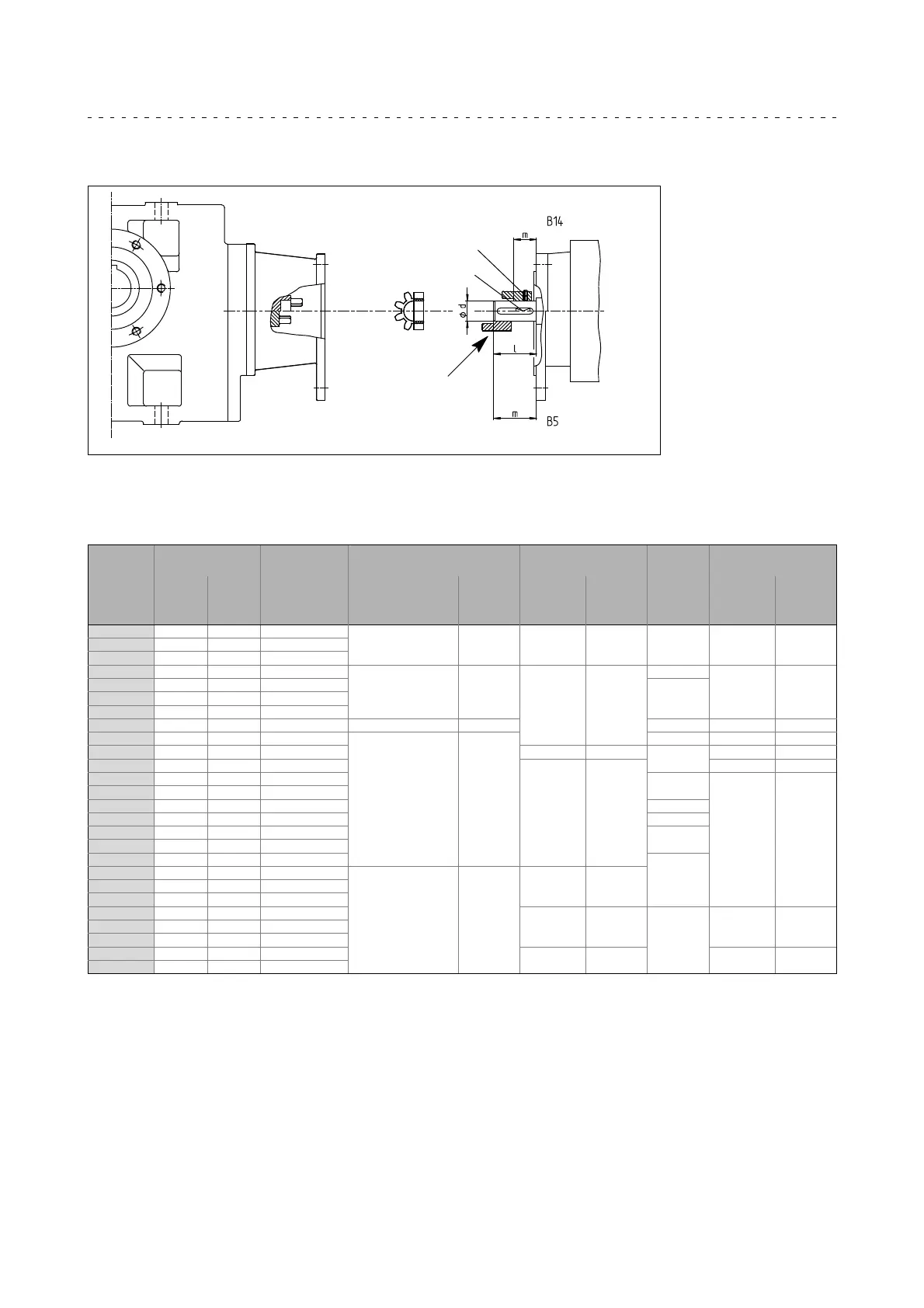

Drive size

Motor shaft Assembly

dimension

Standard hub

Locking screw

Clamping hub Keyway

1)

Clamping ring hub

d

[mm]

max. l

[mm]

m

[mm]

Thread

[mm]

Tightenin

gtorque

[Nm]

Thread

[mm]

Tightenin

gtorque

[Nm]

DIN

6885/1

[mm]

Thread

[mm]

Tightenin

gtorque

[Nm]

1A 11 23 23

M4 1.5 M3 1.34 * M3 1.34

1B 14 30 30

2B 11 23 23

1C 19 40 25

M5 2.0

M6 10.5

B6x6x16

M4 2.9

2C 14 40 25

B5x5x16

3C 14 40 25

4C 14 40 25

6C 11 40 25 --- --- * --- ---

7C 19 40 25

M5 2.0

B6x6x16 M4 2.9

1D 24 50 50 M4 2.9

*

--- ---

2D 19 40-50 50

M6 10.5

M4 2.9

1E 28 30-60 30

B8x7x18

M5 6

2E 24 30-60 30

3E 19 30-60 30 B6x6x18

4E 24 50 50 *

1F 28 30-60 30

B8x7x18

2F 24 30-60 30

3F 24 50 50

*

1G 38 80 80

M8 10

M8 25

2G 28 60 60

3G 38 80 80

1H 42 110 110

M10 69

*

M8 35

2H 48 110 110

3H 38 80 80

1K 55 110 110

M12 120 M10 69

2K 60 140 140

Tab. 3 Attachment of motors to gearboxes with mounting flange

* Use original key for the motor

1)

Key for standard hub and clamping hub

Loading...

Loading...