6

Final Installation Procedures

Perform Triple Leak / Pressure Check (Multi F and Multi F MAX)

After the refrigerant piping installation is complete, perform a triple leak / pressure test to check for leaks at any joints or connections within the

piping system. Perform the Triple / Leak Pressure Check with only the piping system and indoor units / branch distribution units. Use medical grade

dry nitrogen.

Triple Leak / Pressure Procedure

Step 1: Perform the leak / pressure check at 150 psig for fifteen (15)

minutes (standing pressure check).

Step 2: Perform the leak / pressure check at 300 psig for thirty (30)

minutes (standing pressure check).

Step 3: Perform the leak / pressure check at 550 psig for one (1) hour

to make sure the piping system is leak-free. After the gauge reading

reaches 550 psig, isolate the system by first closing the gauge mani-

fold, then close the nitrogen cylinder valve. Check the flared (and any

brazed connections) for leaks by applying a bubble solution to all joints.

Step 4: If the pressure does NOT drop for one (1) hour, the system

passes the test.

Step 5: If the pressure drops, there is a leak and it must be found.

Remove the bubble solution with a clean cloth, repair the leak(s), and

perform the leak / pressure check again.

Perform Deep Evacuation (Multi F)

On Multi F systems, after the leak / pressure check is complete, the deep evacuation procedure must be performed to the refrigerant piping and all

connected indoor units.

Deep Evacuation Procedure

Step 1: Evacuate to static micron level ≤500 for at least one (1) hour.

Step 2: Micron level must remain ≤500 for two (2) hours. If the vacuum

gauge rises and stops, the system may contain moisture; therefore, it

will be necessary to repeat the steps of vacuum break and drying.

Step 3: After maintaining the system in vacuum for two (2) hours,

check if the vacuum gauge rises or not. If it doesn’t rise, then the sys-

tem is properly evacuated.

The triple evacuation procedure is a best practices recommendation for Multi F systems, but mandatory for Multi F MAX systems.

Triple Evacuation Procedure (Multi F MAX)

On Multi F MAX systems, after the leak / pressure check is complete, the triple evacuation procedure must be performed to the refrigerant piping

and all connected indoor units / branch distribution units. Do not just perform the deep evacuation procedure on Multi F MAX systems. The

deep evacuation procedure is insufficient to fully evacuate the extensive piping systems on Multi F MAX products.

Triple Evacuation Procedure Steps

Step 1: Operate the vacuum pump and evacuate the system to the

2,000 micron level. Isolate the pump, and then watch the micron level.

• If the micron level DOES NOT stop rising, there is a leak.

• If the micron level DOES rise above 2,000 micron, re-open the mani-

fold gauges and the vacuum pump valve and continue evacuation back

down to 2,000 micron level.

• If the micron level holds at 2,000 micron, continue to the next step.

Step 2: Break vacuum with 50 psig nitrogen purge for an appropriate

amount of time (this is to “sweep” moisture from piping).

Step 3: Purge nitrogen from the system until the pressure drops down

to 1 to 3 psig.

Step 4: Evacuate to 1,000 micron level. Isolate the pump and then

watch the micron level.

• If the micron level DOES NOT stop rising, there is a leak.

• If the micron level DOES rise above 1,000 micron, re-open the man-

ifold gauges and the vacuum pump valve, and continue evacuation

back down to 1,000 micron level.

• If the micron level holds at 1,000 micron, continue to the next step.

Step 5: Break vacuum with 50 psig nitrogen purge for an appropriate

amount of time.

Step 6: Purge nitrogen from the system until the pressure drops down

to 1 to 3 psig.

Step 7: Evacuate to static micron level ≤500 for at least one (1) hour.

Step 8: Micron level must remain ≤500 for two (2) hours. If the vacuum

gauge rises and stops, the system may contain moisture; therefore, it

will be necessary to repeat the steps of vacuum break and drying.

Test Run

After the triple leak / pressure and evacuation procedures are complete, perform a test run.

Before the Test Run

1. Check that all condensate tubing, refrigerant piping and power wiring, and communication / connection (power) cables are properly connected.

2. Make sure that the gas and liquid service valves are fully open.

Test Run Procedure

3. Operate the system in cooling mode for 15 to 20 minutes.

4. Evaluate performance as the system runs, verifying the outdoor unit, and all indoor units and branch distribution units (Multi F MAX systems

only) are working properly. Make notes as needed to address any issues that might be found.

• Check the system refrigerant charge:

• Measure the pressure from the gas side service valve.

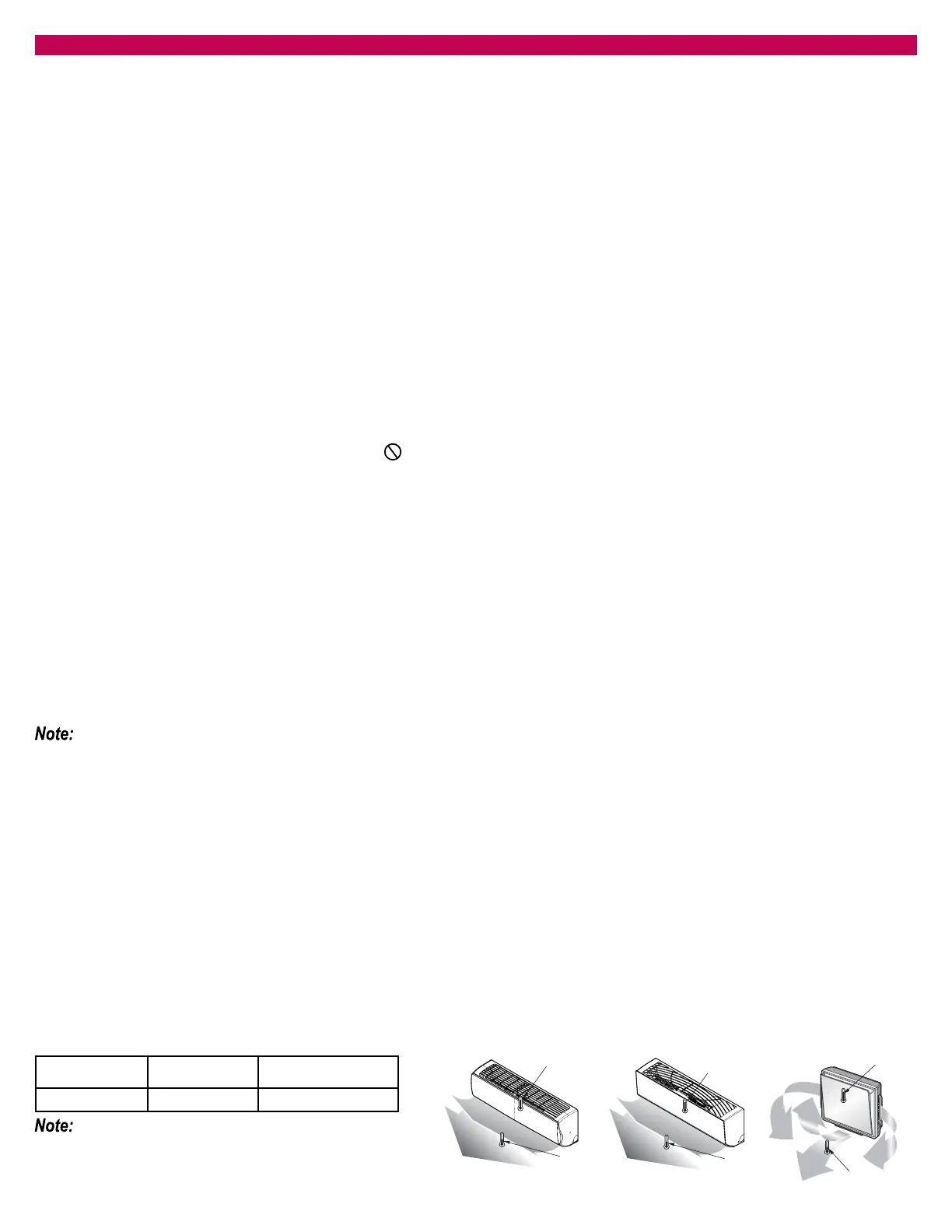

• Measure the indoor unit inlet and outlet air temperatures. Verify the difference between the intake temperature and the discharge is more than

15°F.

• See table below for the optimum condition of the gas side pressure (again, system is in cooling mode).

Refrigerant Type

Outside Ambient

Temperature

Gas Side Service Valve

Pressure

R410A 95°F 120~135 psig

If the pressure is >135 psig, the system is most likely over-

charged, and refrigerant must be removed. If the pressure

is <120 psig, the system is most likely undercharged and

refrigerant must be added.

Outlet

Temperature

Discharge Air

Inlet Temperature

Outlet

Temperature

Discharge Air

Inlet Temperature

Outlet

Temperature

Discharge Air

Inlet Temperature

Inlet and Outlet Temperature Locations on Various Indoor Units.Optimum Conditions of the Gas Side Pressure.

Loading...

Loading...