8

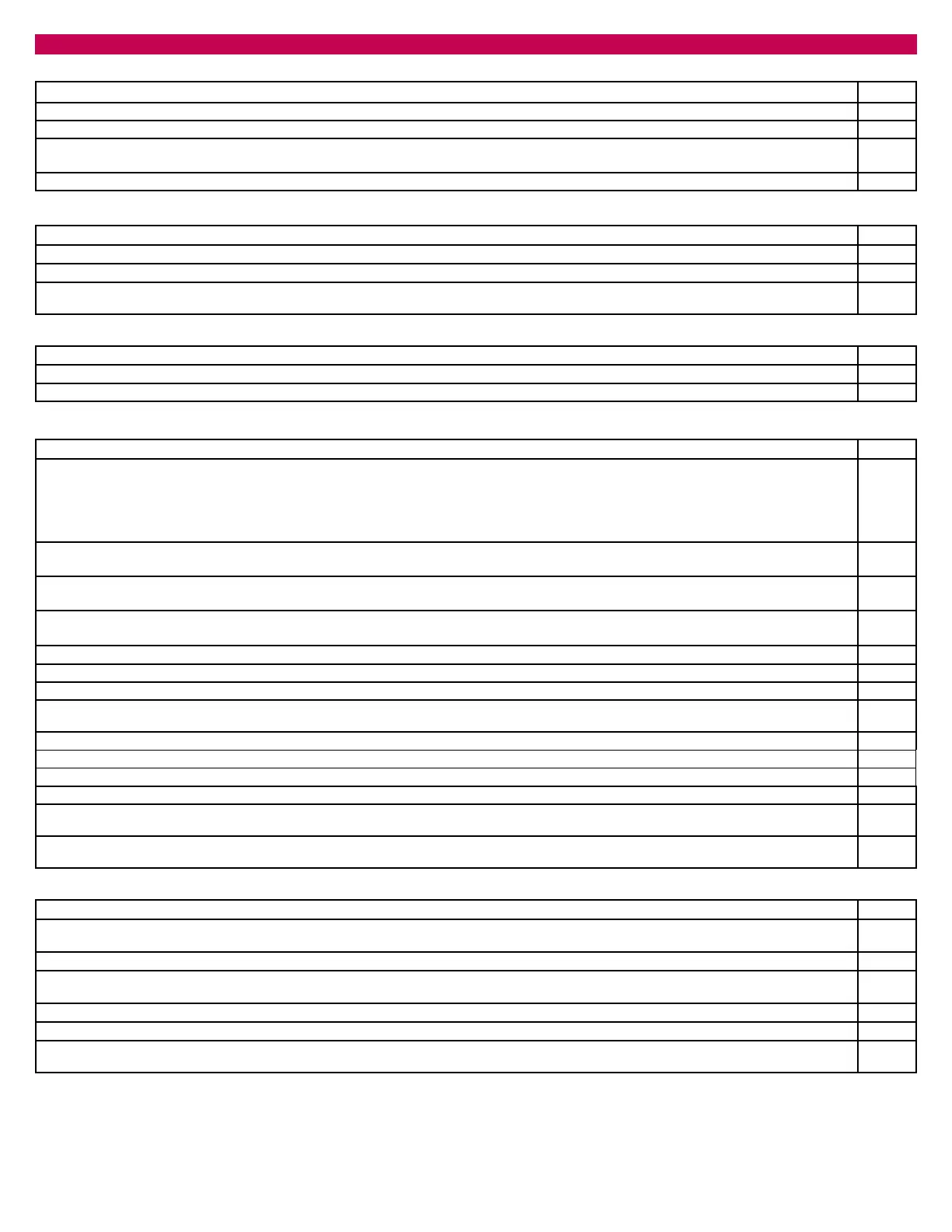

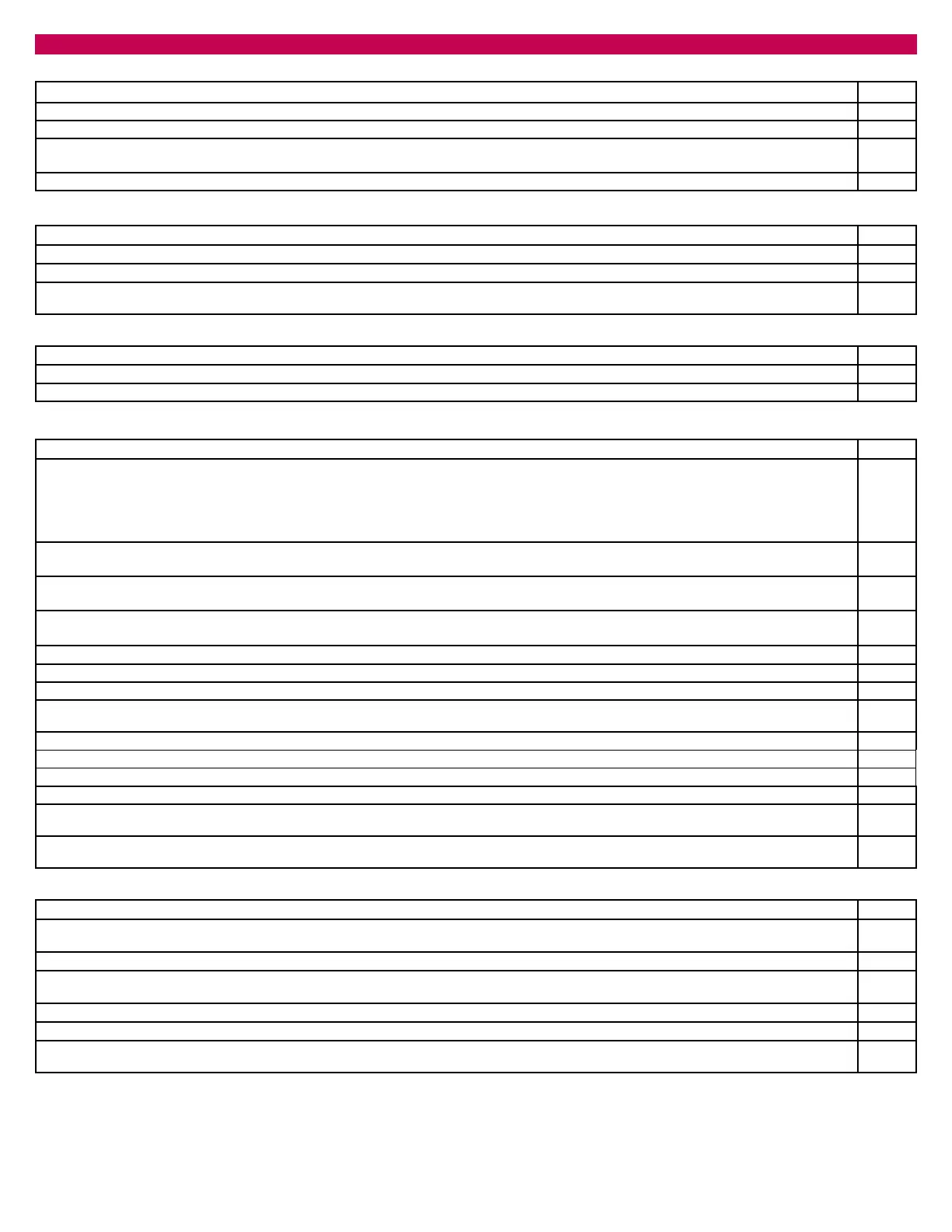

Installation Checklist

Major Component Rough-In

Description Check

Multi F / Multi F MAX outdoor unit was connected properly per local code and the product installation procedures.

All literature and bagged accessories have been removed from the fan discharge (ducted and cassette model indoor units).

All indoor units and branch distribution unit(s) (Multi F MAX only) are installed, properly supported, and located indoors in a non-corro-

sive environment.

Duct work installation completed (ducted indoor units only).

Piping Material, Components, and Insulation

Description Check

Multi-zone duct-free split systems: ACR copper piping rated at the system working pressure was used.

LG Y-branch fitting was used per manufacturer’s recommendations.

All refrigerant pipes and valves were insulated separately. Insulation is positioned up against the walls of the indoor units and branch

distribution units (Multi F MAX only). No gaps shown. Insulation was not compressed at clamps and hangers.

Brazing Practices

Description Check

Use medical grade dry nitrogen for purging during brazing (constant 3 psig while brazing).

15% silver brazing material only.

Refrigerant Piping Design and System

Description Check

You must have in your possession a copy of the “As-Designed” LATS piping tree diagram. BEFORE ANY FIELD PIPE SIZE OR LENGTH

CHANGES ARE MADE, PROPOSED CHANGES MUST BE FORWARDED TO THE DESIGN ENGINEER SO THAT THEY CAN INPUT THE

CHANGES INTO LATS and RE-ISSUE A NEW LATS MULTI V PIPING TREE DIAGRAM. Installer must receive change authorization from

the design engineer, because any change made requires the review of the entire tree diagram and verification that the change did not

impact the size of piping segments in other parts of the system.

All pipe materials were properly stored, capped, and clean. All burrs were removed after cutting and pipe ends were reamed before

brazing.

During refrigerant pipe installation, for each segment of pipe, a record was made of the pipe length (including expansion loops, offsets,

double-back sections), and sizes, as well as the quantity and type of elbows used.

Expansion loops, coils or other acceptable measures are provided where necessary to absorb temperature-change based pipe move-

ment.

A torque wrench and backup wrench were used to tighten all flare connections.

The back side of all flares were lubricated with a small drop of PVE refrigeration oil before tightening flare fittings.

Ensure all field made flares are 45°. Use factory-supplied flare nuts only.

Pipe segments and Y-branch fittings are secured to the structure using a combination of fixed and floating clamps, and all wall penetra-

tions were sleeved.

Pipe insulation was not compressed at any point.

Y-branch fittings were properly INSTALLED per details provided in the Multi F / Multi F MAX Outdoor Unit Installation Manual.

Y-branch fittings were properly SUPPORTED per details provided in the Multi F / Multi F MAX Outdoor Unit Installation Manual.

No oil traps, solenoid valves, sight glasses, filter driers, or any other unauthorized refrigerant specialties were present.

(Optional) High quality R-410A rated full port ball valves (Schrader between the valve body and the indoor units) used at all indoor

units and at will in the refrigerant piping network.

Best practice includes a minimum of 20 inches of straight pipe was installed between long radius 90 degree elbows, and between the

Y-branch fitting and branch distribution unit.

Condensate Pump / Drain Installation

Description Check

Condensate piping installed correctly on indoor units. Material used is acceptable under local code. Insulated as necessary to prevent

condensation.

All condensate vertical risers are equal to or less than 27-1/2 inches from the bottom of the indoor unit.

Indoor units with condensate pumps were level. Units with gravity drains were level or slightly canted toward the drain connection and

are supported properly.

Pumped condensate drain lines were properly connected (do not have traps, and connect to the top surface of the main drain line).

All condensate lines were properly insulated to prevent condensation.

Multi F / Multi F MAX gravity condensate drain line was connected and routed where it properly drains away or, if installed in a mechani-

cal room, was connected and properly routed to a drain terminal.

Loading...

Loading...