21

LUBRICATION AND MAINTENANCE

Lubricate with pressure gun using grease as recommended in Tractor Operator’s Manual

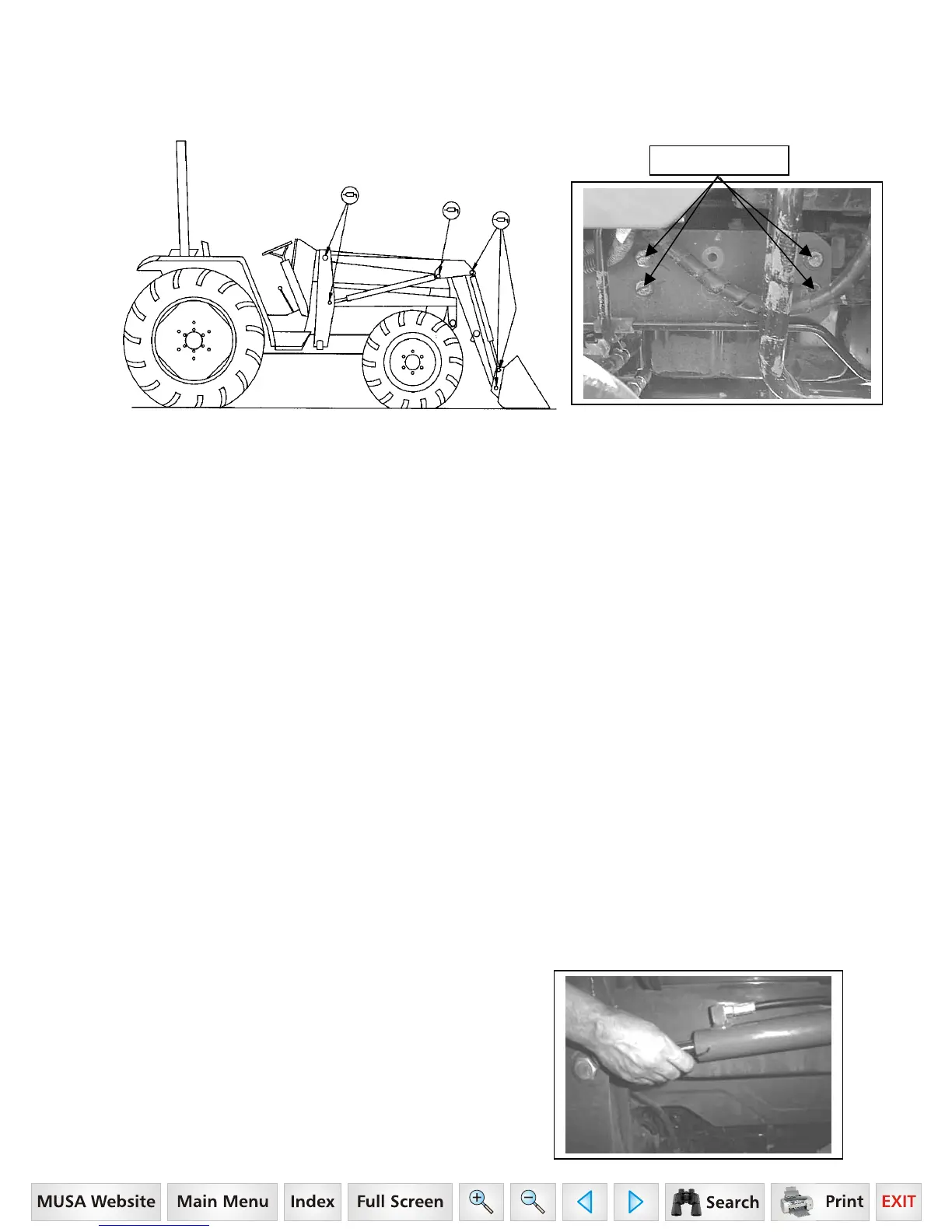

ITEM SERVICE SERVICE INTERVAL

Tractor Rail Bolts (see detail

above)

Re-Torque

First 5 hours then every

20 hours there after

Hydraulic System Oil Level Check Daily/10 hours

Hydraulic System Oil/Filter Replace

As specified in Tractor

Operator’s Manual

Tire Inflation Check Weekly/50 hours

Loader Pivot Points Lubricate Daily/10 hours

Loader Hydraulic Lines,

Hoses, Connections

Check for leaks, wear Daily/10 hours

Lift and Bucket cylinder rod

packings

Check for seepage, service

as needed

Daily/10 hours

Pivot pin clips Check, replace if missing Daily/10 hours

Subframe hinge clamping

bolts

Check, re-torque if necessary Weekly/50 hours

Loader mount hardware Check visually Weekly/50 hours

Loader mount hardware Re-torque Every 50 hours

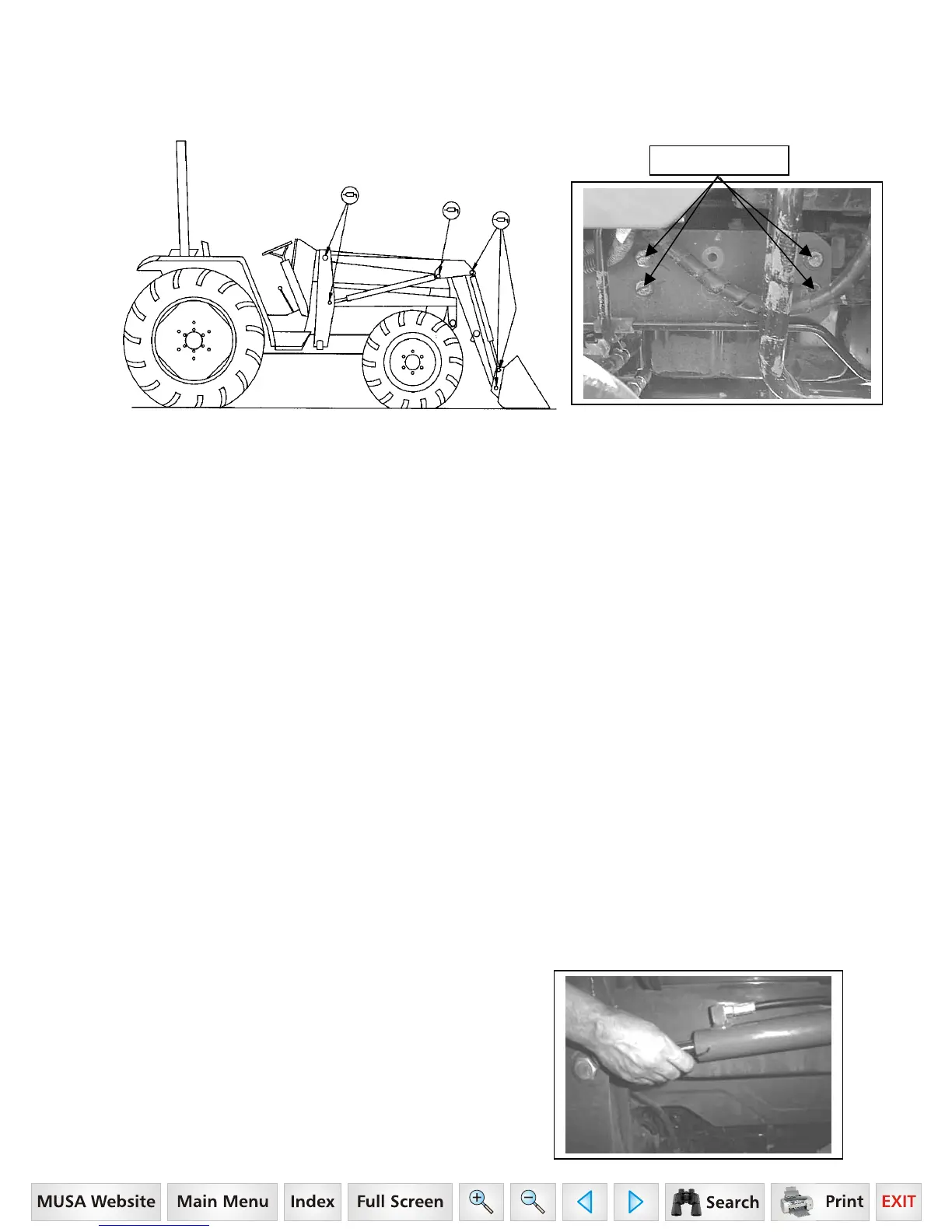

Cylinder Service:

Lift cylinders utilize a set screw type head retaining

design. Routine service is required to keep the set-

screws tight. Refer to figure. Tighten set screws on

all cylinders after initial 10 hours of operation and

then after every 25 hours of operation.

Tractor Rail bolts

16 Series, Model - 2816

Loading...

Loading...