9 ENGLISH

Adjusting the fastening torque

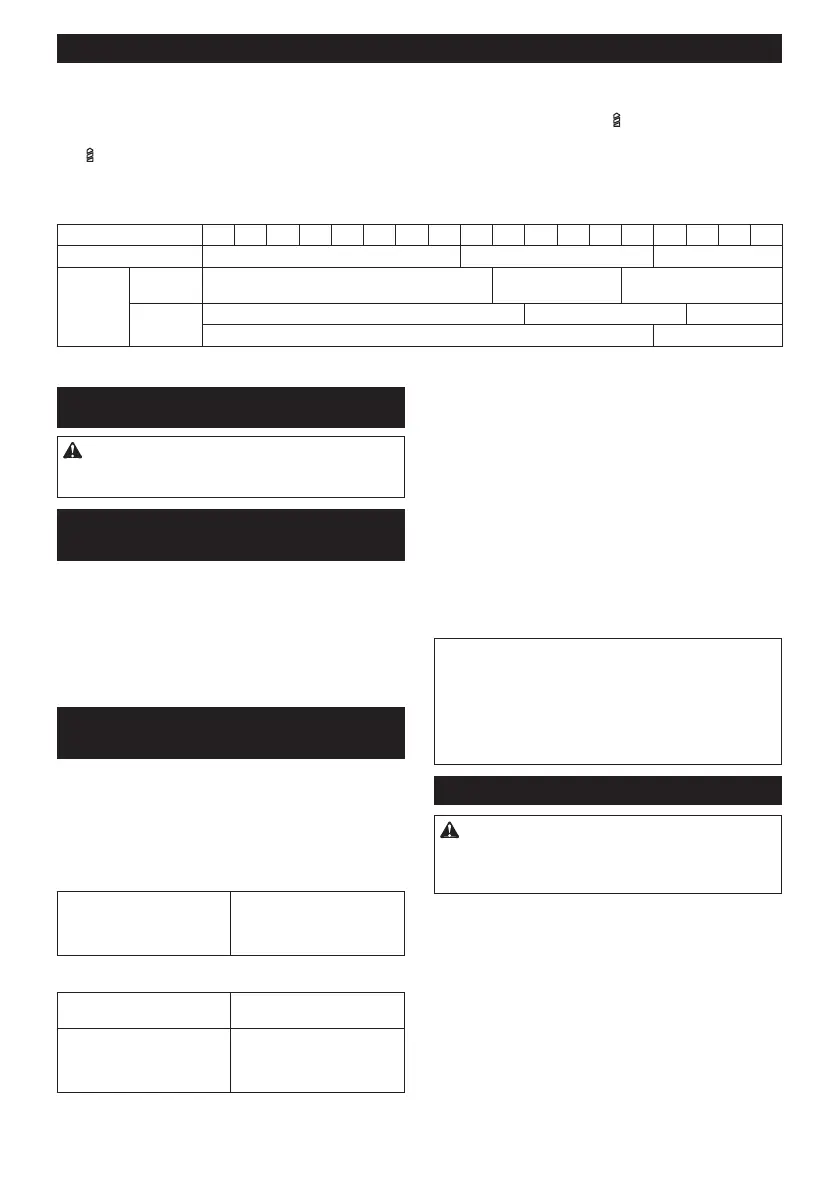

Fig.7: 1.2. Graduation 3.

marking.

the marking.

torque level is required for a particular application.

Graduation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Machine screw M4 M5 M6

Wood

screw

Soft wood

(e.g. pine)

– ø3.5 x 22 ø4.1x 38

Hard wood

(e.g. lauan)

– ø3.5 x 22 –

– ø4.1x 38

ASSEMBLY

CAUTION: Always be sure that the tool is

before carrying out any work on the tool.

Installing or removing driver bit/

drill bit

For Model DF331D (optional accessory)

Fig.8: 1. Sleeve 2. Close 3. Open

Turn the sleeve counterclockwise to open the chuck

as it will go. Turn the sleeve clockwise to tighten the

counterclockwise.

Installing or removing driver bit/

socket bit

For Model DF031D (optional accessory)

Fig.9

For tool with shallow driver bit hole

1. (Note) Bit-piece is not

For tool with deep driver bit hole

-

sleeve as far as it will go.

Fig.10: 1.2. Sleeve

-

end facing in. Then release the sleeve to secure

Fig.11: 1.2. Bit-piece 3. Sleeve

NOTE:

into the sleeve, the sleeve will not return to its original

-

NOTE:

Installing hook

CAUTION: When installing the hook, always

If not, the hook

Fig.12: 1. Groove 2. Hook 3. Screw

the hook, insert it into a groove in the tool housing on

either side and then secure it with a screw. To remove,

loosen the screw and then take it out.

Loading...

Loading...