MAINTENANCE CD5520/YB5520 OPERATOR MANUAL

6-14 Published 07-06-2017, Control # 406-03

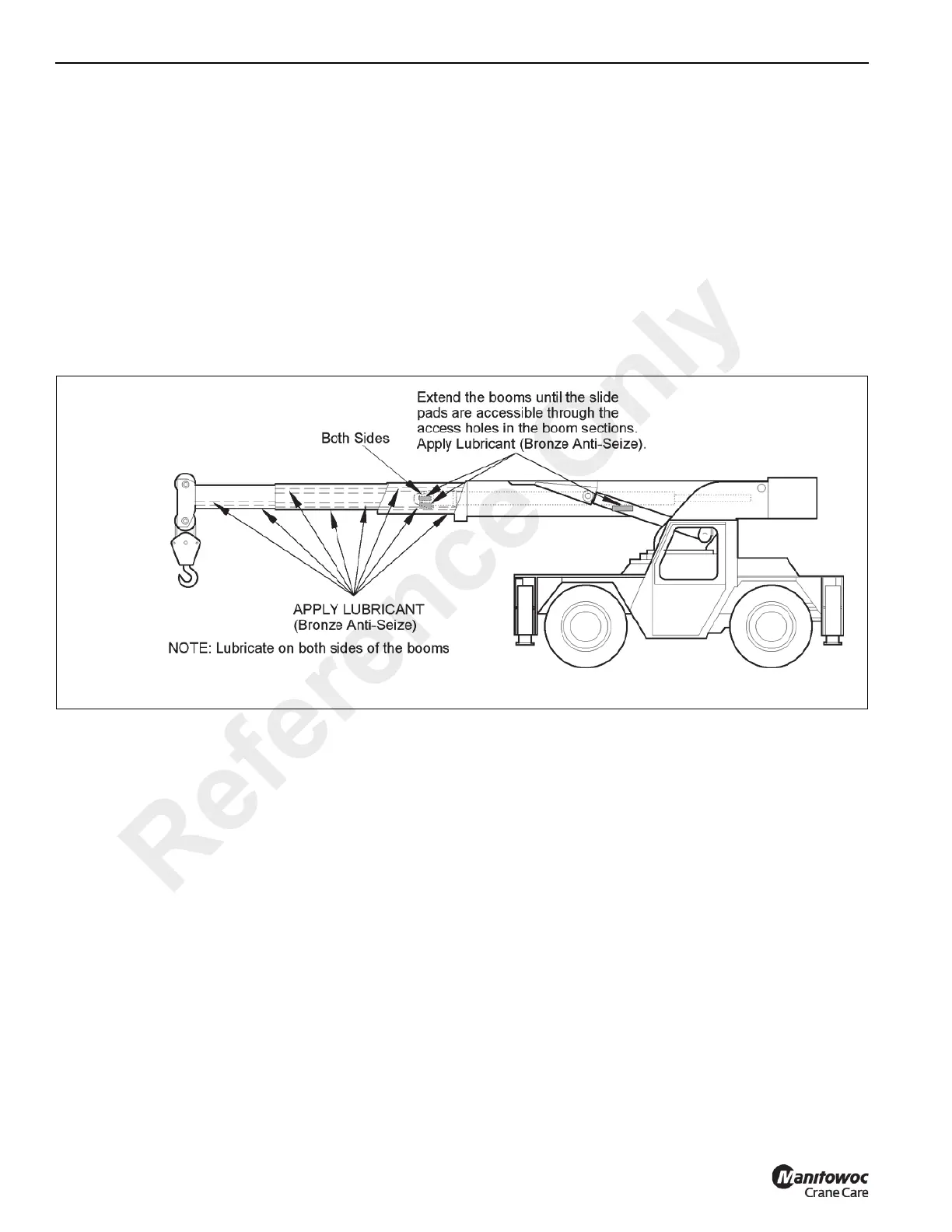

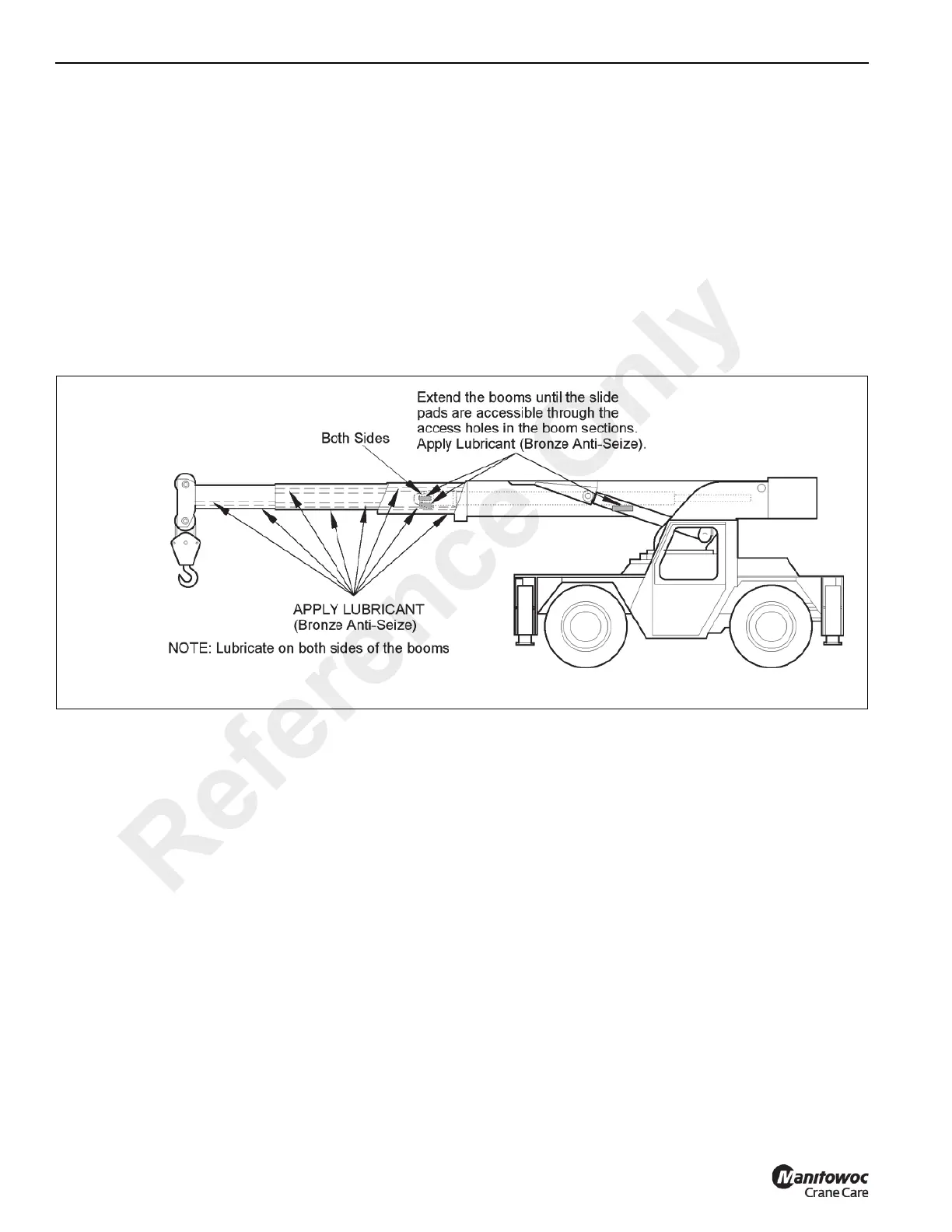

3. Extend boom to position the wear pad access holes

directly above the wear pads on the fourth boom section,

apply grease to the pads using the brush or gun.

4. After grease is applied to all wear pads raise the boom to

the maximum angle and slowly extend the boom to full

extension and slowly retract completely.

5. Repeat steps 1-4 three times to ensure the boom is fully

lubricated.

Side and Bottom Boom Wear Pad

Lubrication

1. Fully extend and set the outriggers.

2. Lower the boom to horizontal.

3. Fully extend the boom and apply grease to the side and

bottom of the 2

nd

and 3

rd

sections with a brush.

4. Raise the boom to about 75° and retract the boom

5. Extend and retract the boom several times until the

grease is evenly spread.

6. Repeat steps 1-3 as necessary to ensure the boom is

fully lubricated.

Lubricate Parking Brake

Apply grease to the fitting on the parking brake. See section

on Lubrication for grease type.

Heater/Air Conditioner Filter

Remove thumb screws to access filter. Clean filter with

compressed air or with mild soap and water. Replace torn or

damaged filter.

100 HOURS OF OPERATION AND OVER

For maintenance and inspections to be performed for 100

hours or over refer to the Service Manual.

For additional engine maintenance guidelines, see the

engine manual furnished with this crane.

CARWELL

®

RUST INHIBITOR

Protecting Cranes From Rusting

Manitowoc Crane Group's cranes are manufactured to high

quality standards, including the type of paint finish

demanded by today's industry. In partnership with our paint

supplier, we are also doing our part to help prevent

premature corrosion of cranes.

Grove cranes will be treated with a rust inhibitor called

Carwell

T32-CP-90. While a rust inhibitor cannot guarantee

that a machine will never rust, this product will help protect

against corrosion on Grove cranes that are treated with this

product.

Carwell is a treatment, not a coating. It contains no silicones,

solvents, CFCs or anything that would be classified as

hazardous under OSHA Regulation 29CRF-19-10.1200. The

product is a liquid blend of petroleum derivatives, rust

inhibitors, water-repelling and water-displacing agents.

Reference Only

Loading...

Loading...