Maintenance

Maintenance Maintenance

Maintenance

Maintenance Maintenance

Maintenance

Schedule Schedule

Schedule

Establishapreventivemaintenanceschedule

basedonthepump’sservicehistory.Scheduled

maintenanceisespeciallyimportanttopreventspills

orleakageduetodiaphragmfailure.

Tighten Tighten

Tighten

Threaded Threaded

Threaded

Connections Connections

Connections

Beforeeachuse,checkallhosesforwearordamage

andreplaceasnecessary.Checktobesureall

threadedconnectionsaretightandleak-free.Check

mountingbolts.Checkfasteners.Tightenorretorque

asnecessary.Althoughpumpusevaries,ageneral

guidelineistoretorquefastenerseverytwomonths.

SeeTorqueInstructions,page10.

Flushing Flushing

Flushing

and and

and

Storage Storage

Storage

Toavoidreandexplosion,alwaysground

equipmentandwastecontainer.Toavoidstatic

sparkingandinjuryfromsplashing,alwaysushat

thelowestpossiblepressure.

•Flushbeforerstuse.

•Flushatthelowestpressurepossible.Check

connectorsforleaksandtightenasnecessary.

•FlushwithauidthatiscompatiblewiththeLP-Gas

beingdispensedandtheequipmentwettedparts.

•Alwaysushthepumpandrelievethepressure

beforelongtermstorage.

Torque Torque

Torque

Instructions Instructions

Instructions

Ifdiaphragmcoverfastenershavebeenloosened,

itisimportanttotorquethemusingthefollowing

proceduretoimprovesealing.

NOTE: NOTE:

NOTE:

Coverscrewshaveathread-lockingadhesive

patchappliedtothethreads.Ifthispatchis

excessivelyworn,thescrewsmayloosenduring

operation.Replacescrewswithnewonesorapply

medium-strength(blue)threadlockertothethreads.

NOTE: NOTE:

NOTE:

Alwayscompletelytorquecoversbefore

tighteningmanifolds.

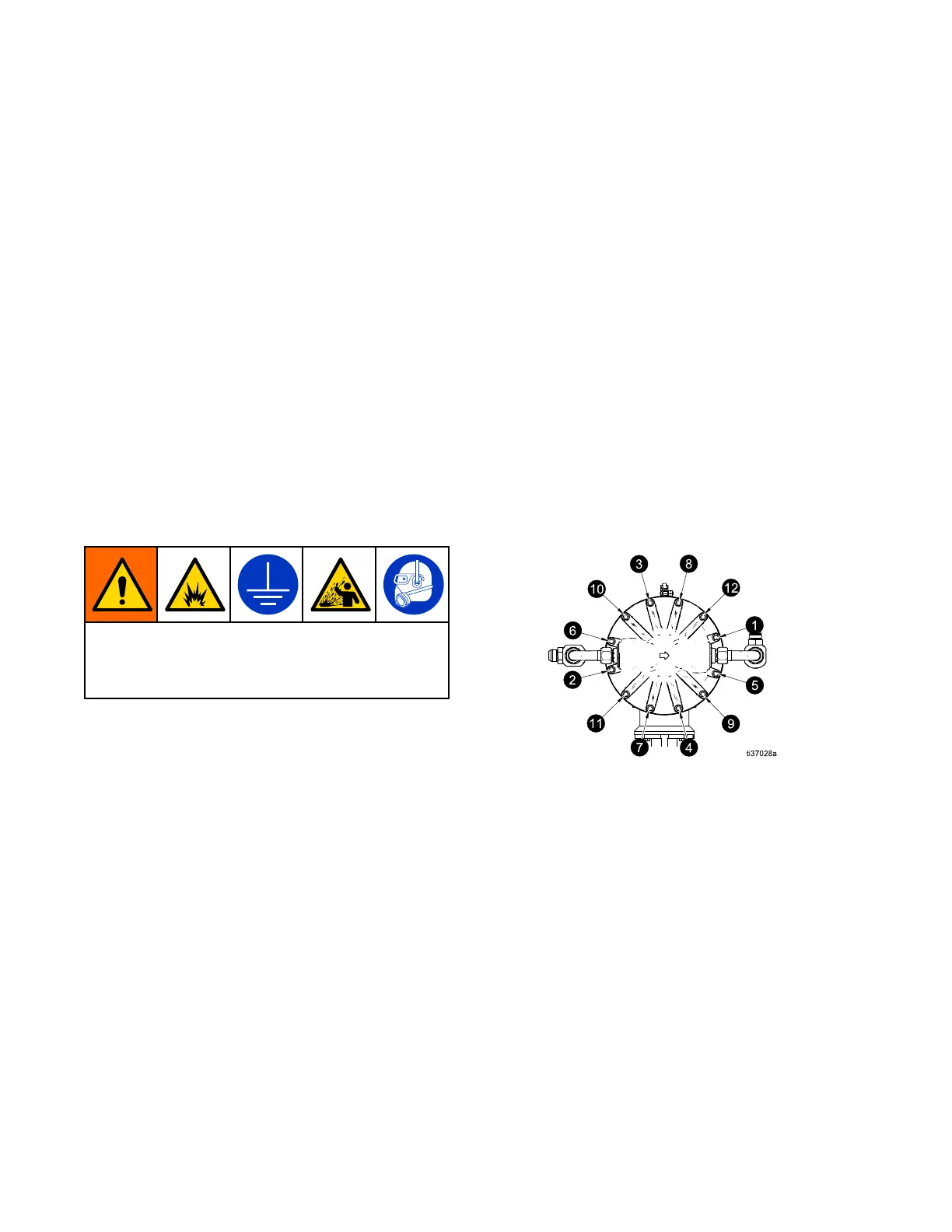

1.Startallscrewsafewturns.Then,turndown

eachscrewjustuntilheadcontactscover.

2.Turneachscrewby1/2turnorlessworkingina

crisscrosspatternintheordershowntospecied

torque.

Diaphragm Diaphragm

Diaphragm

cover cover

cover

screws: screws:

screws:

90in-lb(10.2Nm)

103A6887A

Loading...

Loading...