Installation

Installation Installation

Installation

Tighten Tighten

Tighten

Fasteners Fasteners

Fasteners

Beforeusingthepump,checkand

retorqueallexternalfasteners.Follow

TorqueInstructions,page10.Aftertherst

dayofoperation,retorquethefasteners.

Moving/Mounting Moving/Mounting

Moving/Mounting

the the

the

Pump Pump

Pump

NOTICE NOTICE

NOTICE

Thepumpisheavy.Topreventdamagefrom

dropping,alwaysuse2peopleoralifttomovethe

pump.Donotusethemanifoldstoliftthepump.

Useatleastonestrapattachedtothecenter

section.

1.Forallmountings,besurethepumpissecured

withfourscrewsthroughthemountingstandfeet.

SeeDimensions,page12forsizeandlocationof

mountingstandholes.

2.Makesurethesurfaceisatandthatthepump

doesn’twobble.

3.Foreaseofoperationandservice,mountthe

pumpsopumpinletandpumpoutletportsare

easilyaccessible.

Grounding Grounding

Grounding

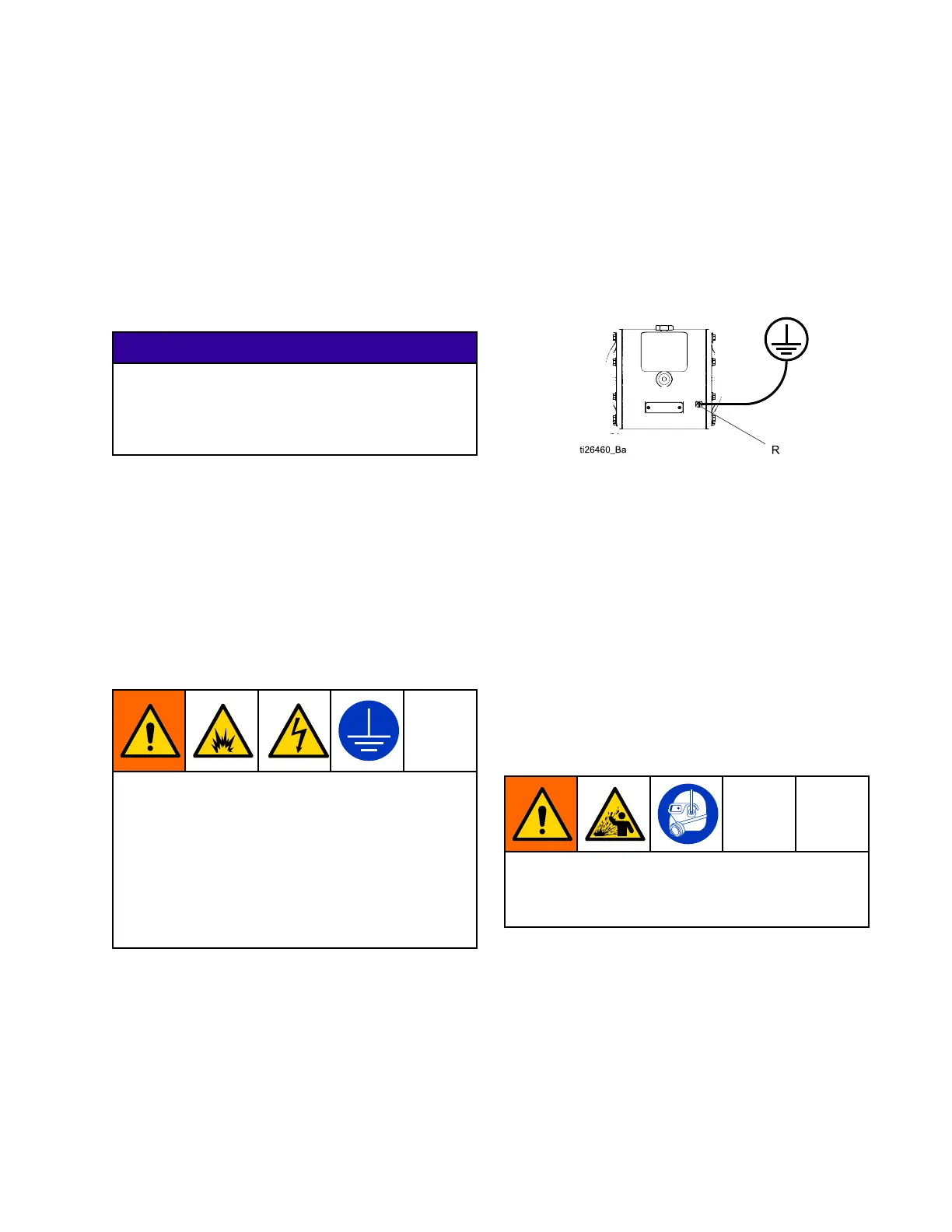

Theequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

•Always Always

Always

groundtheentirepumpsystemas

describedbelow.

•Followyourlocalrecodes.

Beforeoperatingthepump,groundthesystemas

explainedbelow.

•System System

System

equipment: equipment:

equipment:

Alltanksandaccessoriesof

thecompleteextractionsystemmustbegrounded

totrueearthground.

•ON/OFF ON/OFF

ON/OFF

switch switch

switch

or or

or

motor motor

motor

starter: starter:

starter:

Groundthrougha

properconnectiontotheelectricalsystem.Refer

tothemanufacturer’sinstructionsforgrounding

instructions.

•Motor: Motor:

Motor:

Motorshaveagroundscrewintheelectrical

box.Useittogroundthemotortotheelectrical

system.

•Pump: Pump:

Pump:

Loosenthegroundingscrew(R).Insertone

endofa12-gaugeminimumgroundwirebehind

thegroundscrewandtightenthescrewsecurely.

Connecttheclampendofthegroundingwiretoa

trueearthground.

Checkyoursystemelectricalcontinuityafterthe

initialinstallation,andthensetuparegularschedule

forcheckingcontinuitytobesurepropergrounding

ismaintained.Theresistanceshouldnotexceed1

megohm.

CO CO

CO

2 2

2

Cylinder Cylinder

Cylinder

PumpissuppliedwithCO

2

regulatorandhose.Install

asshowninGeneralInformation,page6.TheCO

2

cylindermustbeprovidedbycustomer.Thisisa

standard(#20)5lb.tankofindustrialCO

2

available

fromweldingsupplystores.Atankshouldlastfor

hundredsofpumpoperatinghours.

Pump Pump

Pump

Inlet Inlet

Inlet

Thispumpisnotintendedtopumpliquid.Liquid

insidethepump,ifheated,cancreatearapidrise

inpressureduetothermalexpansion,whichcan

resultinequipmentruptureandseriousinjury.

•ConnectanLP-Gasratedhosefromtheextractor

tothepumpinletport.Theportis1in.JIC-male.

•MVPrecommendsinstallationofanauxiliary

devicebeforethepumpinlet,ifnecessary,to

prevententranceofliquidintothepump.

Pump Pump

Pump

Outlet Outlet

Outlet

ConnectanLP-Gasratedhosefromthepumpoutlet

porttotheextractor.Theportis1in.JIC-male.

3A6887A

7

Loading...

Loading...