Replace the Raw Water Pump Impeller

Change the raw water pump impeller annually. This is

extremely important! Through normal wear and tear, the impel-

ler usually lasts no more than one season, even under ideal con-

ditions. If it does not function properly—and it will not when it is

worn—it can cause serious engine overheating and potentially

void your warranty!

MasterCraft recommends that this procedure be performed by a Mas-

terCraft service technician. If, however, you wish to complete this function your-

self, detailed instructions are included under Before Each Use, Check the Impel-

ler section of this manual, where documentation was provided to assist boat

owners who experience overheating problems or who boat in “dirty” water.

2007 MasterCraft Owners Manual - Page 15-12

Have an Engine Tune-Up Performed

A complete engine tune-up, including replacement of the PVC valve,

sparkplugs,distributorcap,rotorandignitionwires(ifneeded)shouldbe

performed annually. Also, some engines require adjustments for spark, dwell

and idle. All of these functions require special knowledge, tools and test

equipment.

For this reason, MasterCraft strongly recommends having the engine

tune-up performed by your dealer.

Change Transmission Fluid

In order to thoroughly drain all the old transmission uid, you will need

to run the boat engine for a period of at least fi ve minutes. Do not run your

engine without it being in water, unless you have the appropriate professional

hook-up available to protect the engine and drive-train components. If this is not

available to you and if you do not wish to run your boat in the water and then

remove it for this procedure, have your MasterCraft service technician perform

this function because he has the proper equipment to protect your engine as it

runs while it is out of the water.

Step 1: Ensure the engine is OFF and the engine safety starting switch is dis-

connected. Be certain that the throttle/shift control lever is in neutral.

Thetransmissionfluidmustbewarmedup.

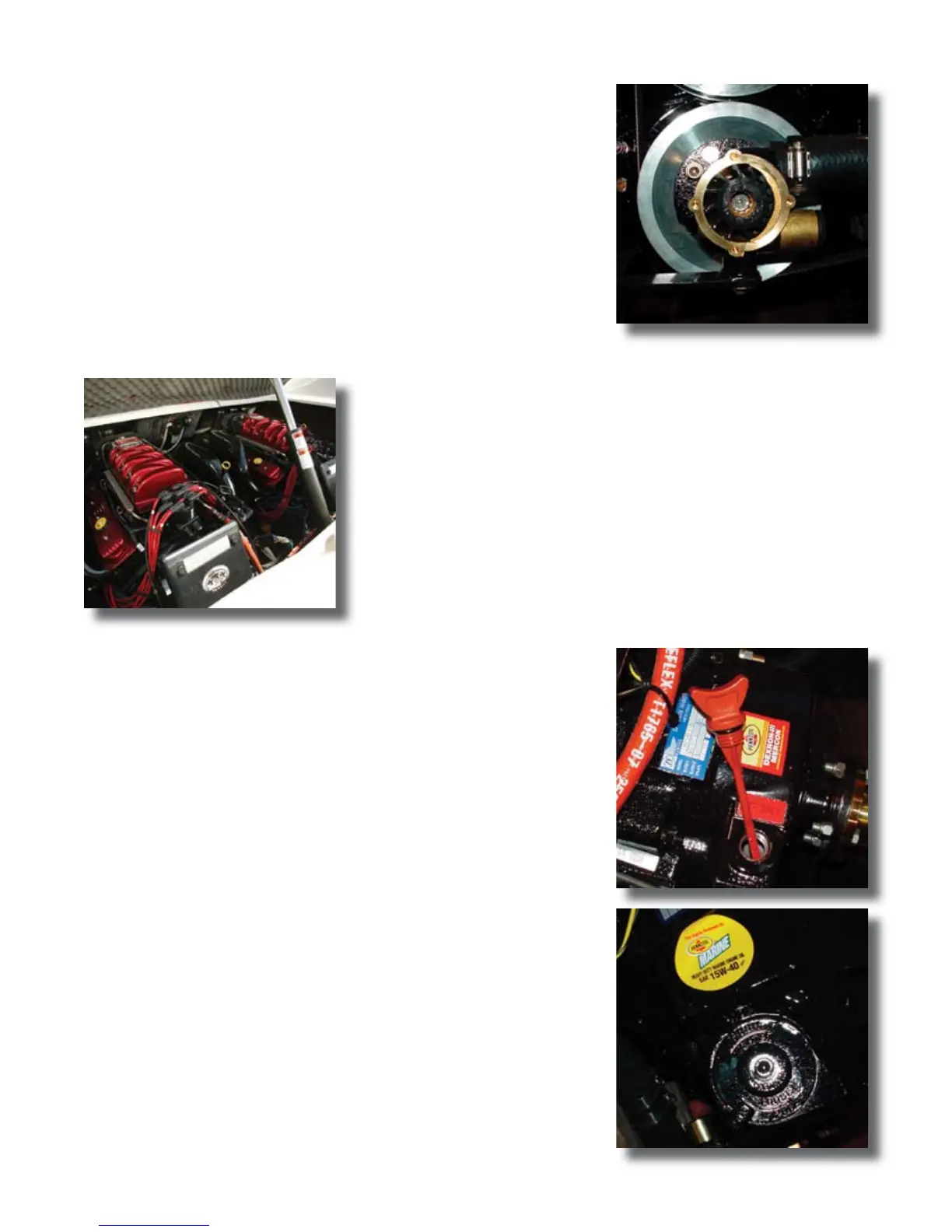

Step 2: Open the engine compartment and locate the transmission.

Step 3: Remove the transmission dipstick.

Step 4: Use a suction pump through the transmission dipstick opening to re-

movethefluidfromthetransmissioncasing.

Step 5: On a 1:1 transmission,thelterislocatedbeneaththetransmis-

sion housing.

On a PowerSlot transmission,thelterisaccessedthrougha

round plug on the side of the transmission housing.

Loading...

Loading...