MASTERCRAFT TRAILERS

26-6

As part of the regular maintenance, keep the axle assembly properly lubricated. This procedure is best

performed by your MasterCraft dealer. The fill plug in the hub nose must be removed so that 80- to 90-

weight motor oil can be added. “Never-seize compound” is applied to the fill plug, which is re-installed and

torqued to 7-ft-lbs.

Lug Nuts or Wheel Bolts

Loose lug nuts can cause

more than just an annoying

wheel wobble–you could lose

a wheel. Before each trip check

for loose or missing lug nuts/

wheel bolts.

When tightening the lug

nuts, use the correct sized-

wrench. The wrong size can

round-off the lug nuts and ren-

der them useless. If you lose a

lug nut, replace it promptly. The

correct size varies with differ-

ent models, so you should verify

the information with your

MasterCraft dealer.

Take special care to ensure

that the replacmenent lug nut

is the correct type. While the

threads of the lug nut may match, it may be a size that

does not hold the wheel securely against the hub, even

when fully tightened. Be certain a replacement lug nut is

an exact match for the original.

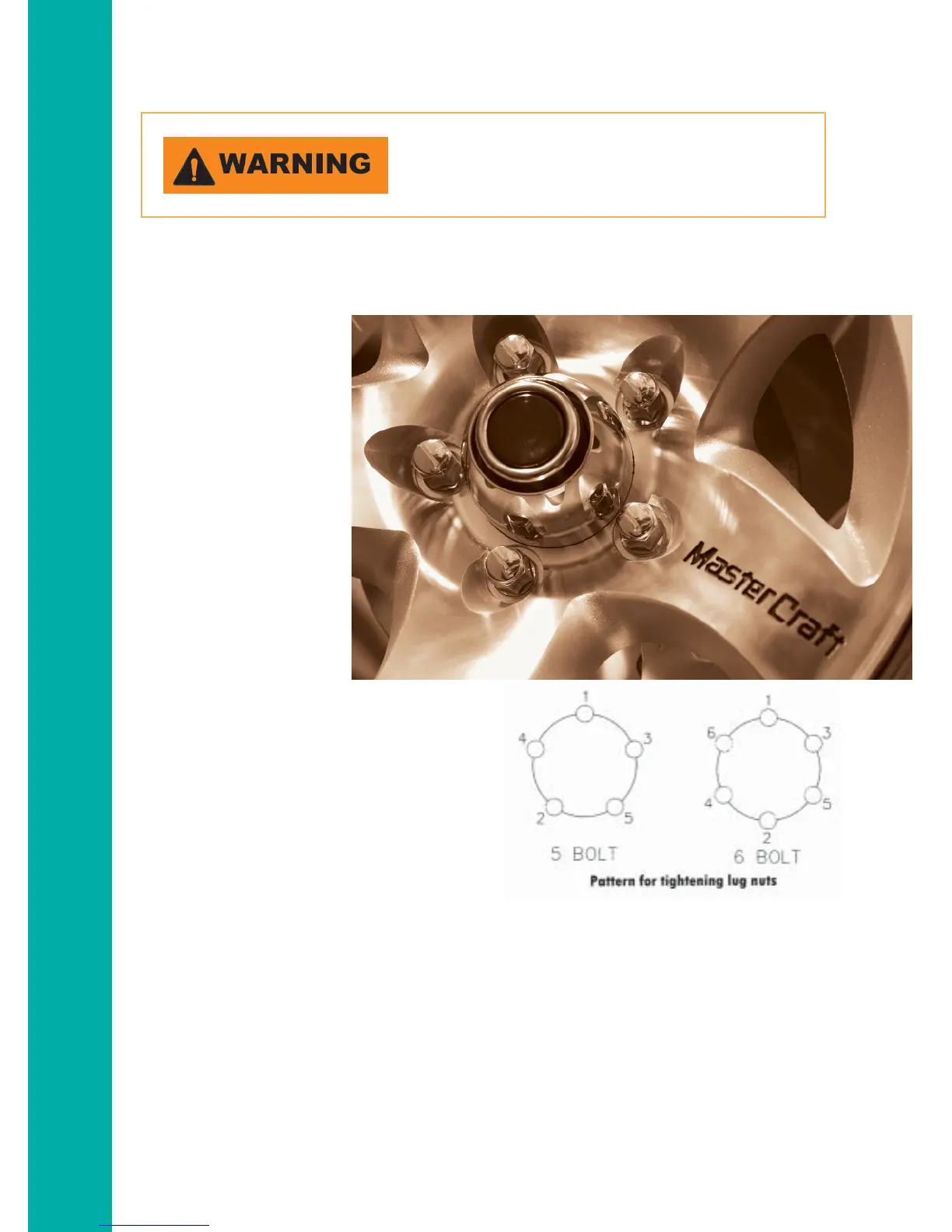

Use the following pattern to tighten lug nuts. On

first torquing pass: Bring up to 45-ft-lbs. On sec-

ond pass: Bring up to 70-ft-lbs. On third pass:

Bring up to 90-ft-lbs.

Lubrication

Currently, trailers feature oil-bath bearings. Earlier models were equipped with easy lubricating hubs. How-

ever, water invades and seeps through the smallest opening. When a warm hub is submerged in cold water, any

air inside the hub will contact and draw water through the best of seals.

Trailers equipped with the Bearing Buddy II with Auto Check simplify the process of keeping watch for proper

lubrication. If the blue ring is fully extended (about 1/4-inch extruded), you have adequate lubrication. As the grease

dissipates, the ring will move back into the shell. When the blue ring is flush with the Bearing Buddy shell, it is time

to re-lubricate.

Your best protection against wheel bearing damage from the water is to always keep your wheel assembly

properly lubricated. If the wheels have been in the water, the bearings should be re-packed if the trailer remains

unused for two weeks or longer. When on a trip, make it a habit to check the wheel hubs every time you stop for

gas or refreshments. If the hub feels abnormally hot, the bearings should be inspected before continuing your trip.

Also keep the wheel bearings lubricated. Failure to do so may

cause failure and possible wheel loss, which may result in

serious injury or death or property damage.

Loading...

Loading...