ANNUAL MAINTENANCE

19-7

Check the ballast pump impeller

This applies only to boats equipped with some type of ballast system. The

number of ballast pumps varies from system to system. You may need guid-

ance from your dealer to locate any and all pumps.

Step 1: Remove two of the cover screws and retain the screws for

the reinstallation process. Swing the cover out of the way to allow

access to the impeller location.

Step 2: Using the needle-nose pliers, pull the old impeller out of

the casing.

Step 3: Install the new impeller. (It is intentionally larger than the case.

While gently squeezing it in, ensure that the paddle wheels angle in the same

direction--counterclockwise--all the way around.)

Step 4: Slide the plate back into place. No silicone is necessary. Due

to the built-in gasket, tightening the screws should prevent leakage.

Inspect complete fuel system for leakage

Although your boat engine is similar to your automobile engine, the engine compartment differs substantially. The

underside of your automobile engine compartment is totally open to the atmosphere. This allows complete air circulation and

ventilation. Your boat engine is housed in a closed compartment, the underside of which is the bottom of the boat.

The enclosed engine compartment limits the ventilation of gasoline and oil fumes. Because confined gasoline vapors

mixed with a little air can form an explosive atmosphere, it is important to be especially vigilant in performing the following

two operations:

Step 1: Run your bilge blower for at least four minutes to ventilate the bilge area each time before starting

the engine.

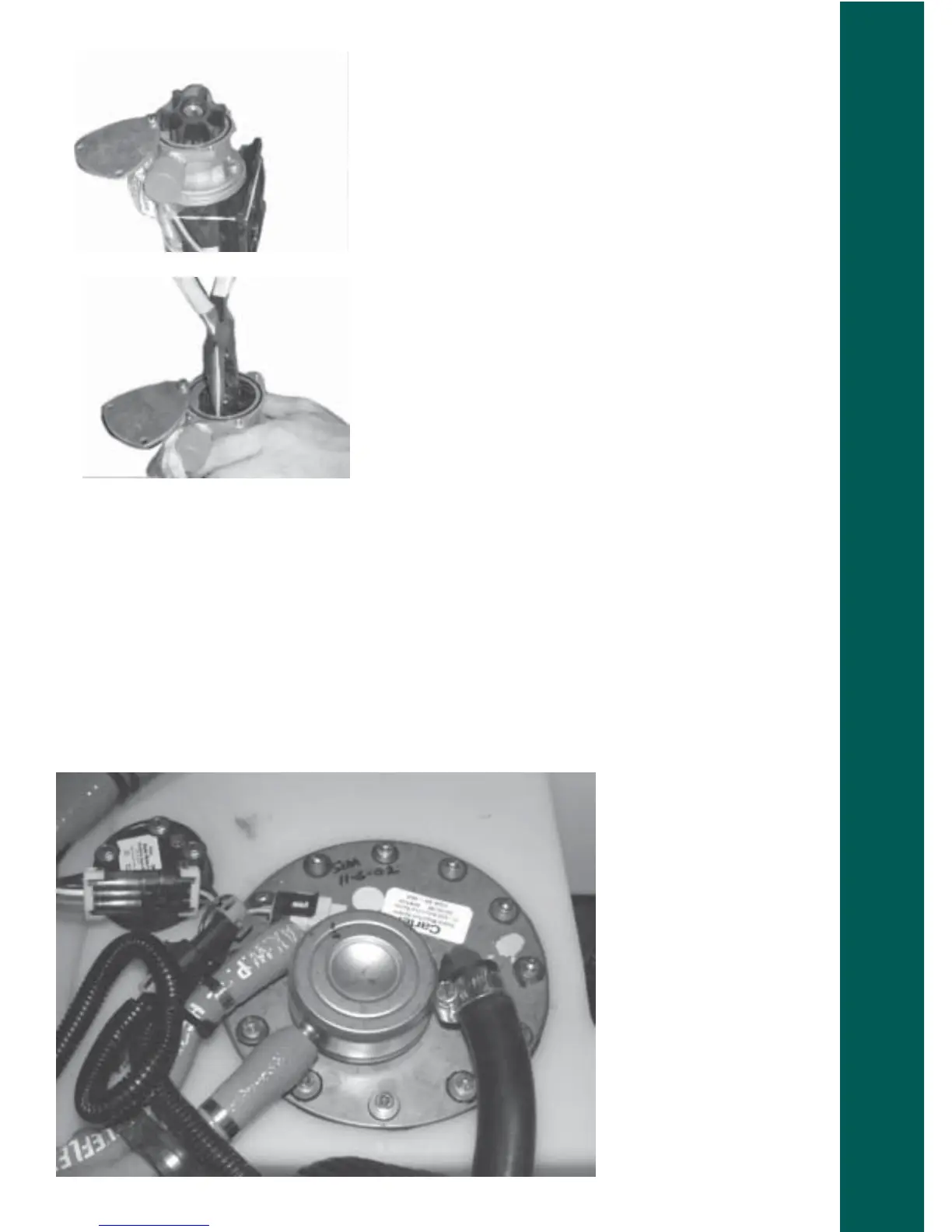

Step 2: Inspect your boat

bilge area under the engine for

the evidence of oil and

gasoline–or any gasoline odor.

This inspection should take

place the first time the boat is

started each day. Raise the

engine cover and visually look

at the bilge area under the

engine.

Loading...

Loading...