McQuay IM 987 109

Maintenance

BOA Concentric Inserts

1 Be sure that BOA Concentric collar is fitted square and

snug against the shoulder on the inner ring.

2 Torque BOA Concentric collar cap screw to torque

recommended in Table 21.

Note: AF = DWDI AF, SWSI = AF Plenum Fan

Monitor Installed Bearing

After bearing has been run for several minutes, and again after

several hours, check bearing for excessive noise or vibration.

Shutdown machine and check housing temperature: typical

applications operate at 100°F - 105°F (38°C - 66°C). Tighten

all locking devices after 500 hours or 3 months, whichever

comes first.

Propeller Exhaust

For information, see "Propeller Exhaust Fan Option"‚ page 91.

Vibration Levels

Each unit as shipped is trim balanced to operate smoothly. To

provide satisfactory operation after shipping and installation,

use accepted industry guidelines for field balancing fans. See

Table 22.

Note: Excessive vibration from any cause contributes to

premature fan and motor bearing failure. Monitor overall

vibration levels every six months of operation. An

increase in levels is an indication of potential trouble.

Vibration Causes

1 Wheel imbalance.

a Dirt or debris on wheel blades.

b Loose setscrews in wheel hub or bearing-to-shaft.

c Wheel distorted from overspeed.

2 Bent shaft.

3 Faulty drive.

a Variable pitch sheaves—Axial and radial runout of

flanges; uneven groove spacing; out of balance. Also

similar faults in driven sheave.

b Bad V-belts; lumpy, or mismatched; belt tension too

tight or too loose.

4 Bad bearings, loose bearing hold-down bolts.

5 Motor imbalance.

6 Fan section not supported evenly on foundation.

Periodic Service and Maintenance

1 Check all moving parts for wear every six months.

2 Check bearing collar, sheave, wheel hub setscrews,

sheave capscrews, and bearing hold-down bolts for

tightness every six months.

Setscrews

Setscrews are used to lock bearings, sheaves, locking collars,

and fan wheels to their shafts. They must be checked

periodically to see that they have not loosened. If this is not

done, severe equipment damage could occur.

Refer to Table 23 and check the tightness of all setscrews with

a torque wrench. Note that if the return fan bearings setscrews

must be retightened, a special procedure is required to equally

load both bearings (see “Return Fan Bearing Setscrews”

below).

Return Fan Bearing Setscrews

Because the return fan is mounted on a vertical shaft, the

following procedure must be used to retighten any return fan

bearing setscrews that have loosened. This procedure will

provide that both bearings are equally loaded. If one bearing is

carrying the entire weight of the fan, it could fail prematurely.

1 Loosen the fan belts.

2 Support the weight of the fan and the fan shaft with

timbers or some other suitable means (see the fan shaft

support in Figure 119, page 110). Important: To

maintain proper drive alignment and fan-to-tunnel

clearance, the fan and shaft must not drop at all when the

setscrews are loosened in Step 4.

3 Verify that the upper shaft collar is securely fastened to

the shaft. Check the setscrew torque.

4 Loosen the upper and lower bearing setscrews. The

entire weight of the fan and shaft is now supported by the

fan shaft support.

5 Retighten all bearing setscrews to the torque

specification given in Table 23. Remove the fan shaft

support and re-tension the belts.

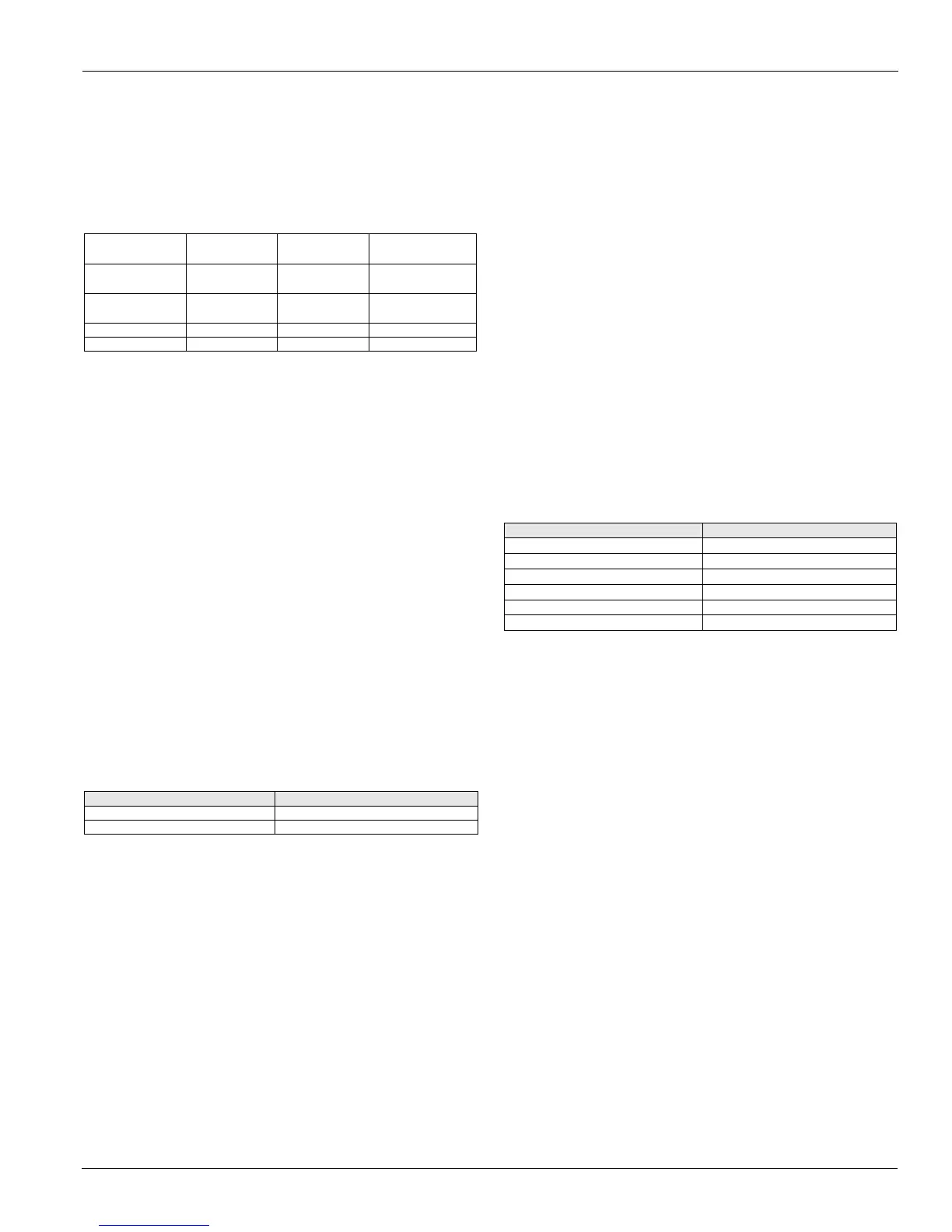

Table 21: Recommended Torque Values for Concentric

Locking Bearing/Shaft Size

Fan Size (in) Bore Size (in)

Torx Screw

Size

In lbs.

27 (AF)/40 & 49

(SWSI)

2-3/16 T-30 180

30 & 33 (AF)/44

(SWSI)

2-7/16 T-45 400

36 (AF) 2-11/16 T-45 400

40 (AF) 2-15/16 T-45 400

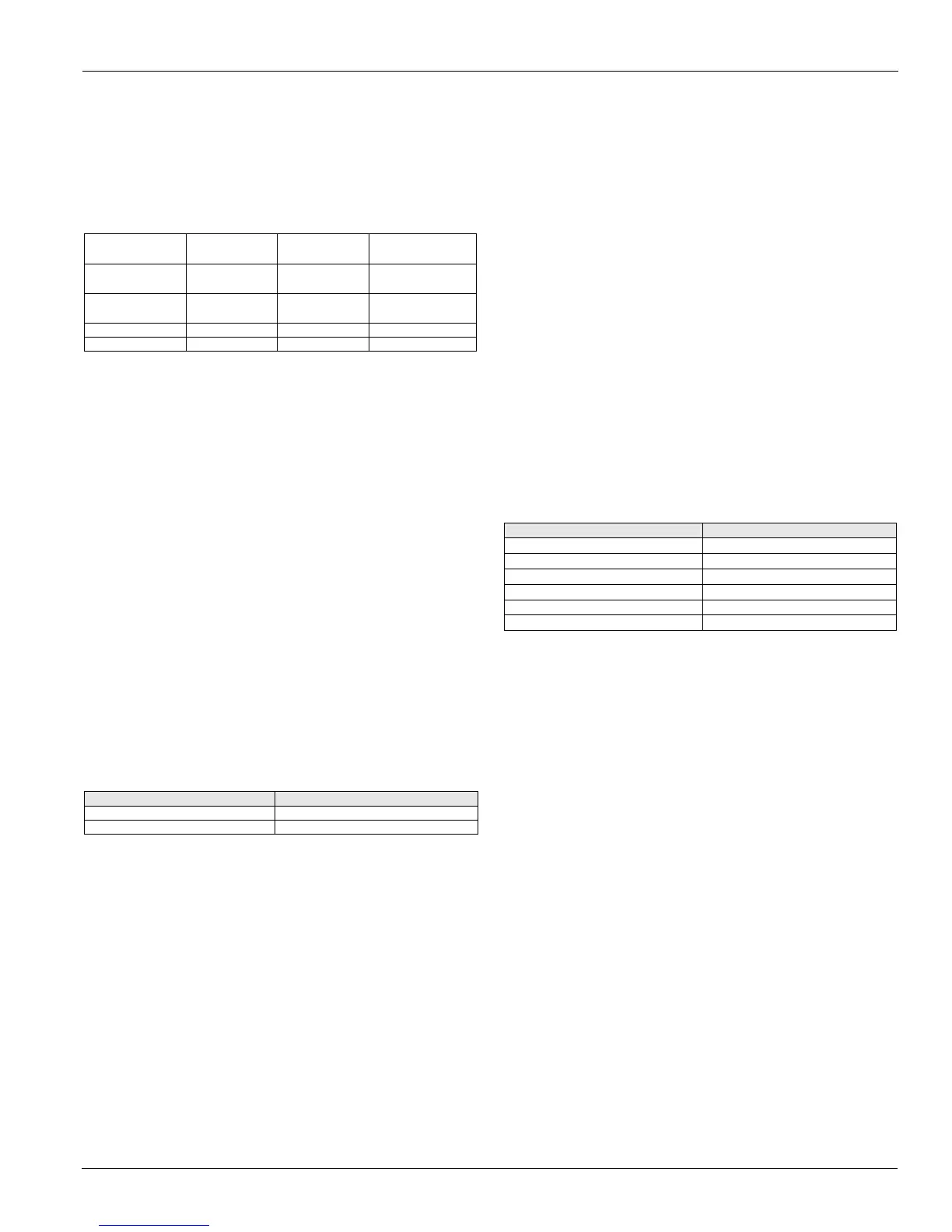

Table 22: Vibration Levels

Fan speed (RPM) Vibration

800 or less 5 mils maximum displacement

801 or greater 0.20 in/sec maximum velocity

Table 23: Setscrew Minimum Torque Specifications

Setscrew diameter (in.) Minimum torque (ft.lb)

1/4 5.5

5/16 10.5

3/8 19.0

7/16 29.0

1/2 42.0

5/8 92.0

Loading...

Loading...