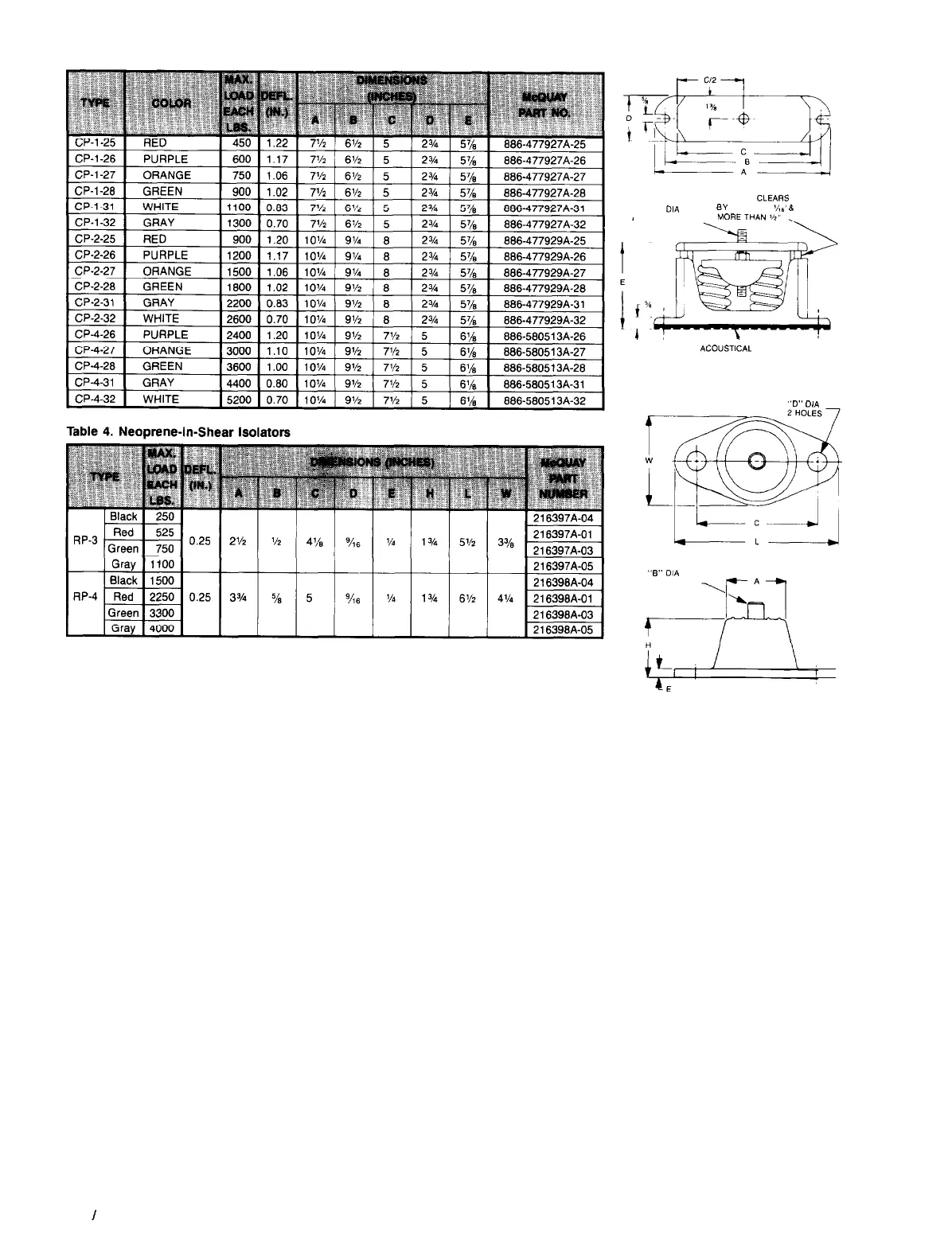

Table 3. Spring Flex Isolators

Figure 4. Spring Flex Mountings

ADJUST MOUNTING SO UPPER

HOUSING CLEAR3 LOWER HOUSING

‘/2”

DIA

SY

AT LEAST %S 8 NOT

POSITIONING PIN

ACOUSTICAL NON-SKID

NEOPRENEPAD

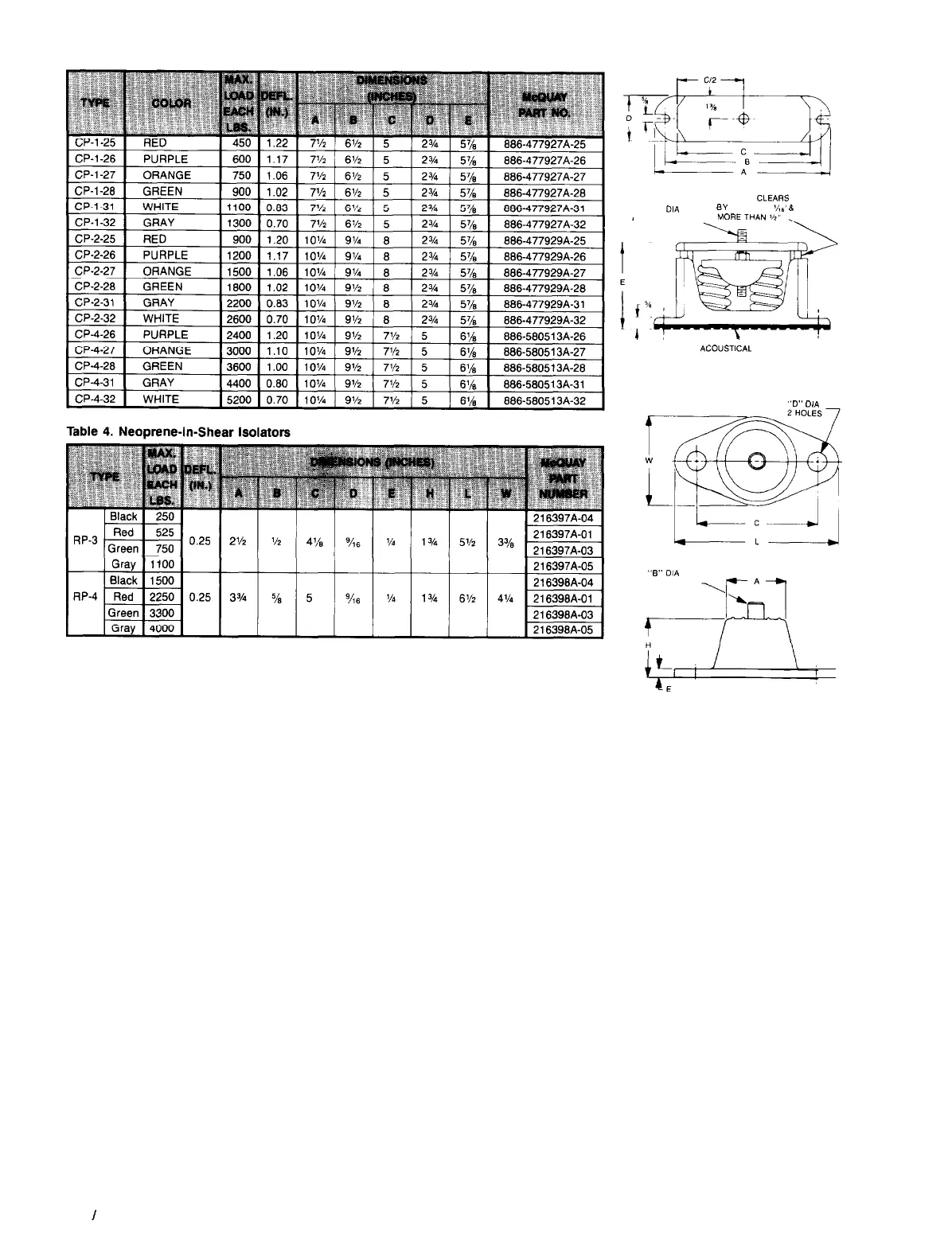

Figure 5. Single Neoprene-in-Shear

Mounting

“D”

D,A

“S”

DIA

POSITIONING PIN

WATER PIPING

GENERAL

Since regional piping practices vary considerably, local or-

dinances and practices will govern the selection and installa-

tion of piping. In all cases local building and safety codes and

ordinances should be studied and complied with.

All piping should be installed and supported to prevent the

unit connections from bearing any strain or weight of the

system piping.

Vibration eliminators in all water piping connected to the

unit are recommended to avoid straining the piping and

transmitting pump noise and vibration to the building

structure.

It is recommended that temperature and pressure indicators

be installed within 3 feet of the inlet and outlet of the shells

to aid in the normal checking and servicing of the unit.

A strainer or some means of removing foreign matter from

the water before it enters the unit or the pump is recom-

mended. It should be placed far enough upstream to prevent

cavitation at the pump inlet (consult pump manufacturer for

recommendations). The use of a strainer will prolong pump

life and thus keep system performance up.

A preliminary leak check of the water piping should be

made before filling the system.

Shutoff valves should be provided at the unit so that nor-

mal servicing can be accomplished without draining the

system.

A WATER FLOW SWITCH OR PRESSURE DIFFERENTIAL

SWITCH MUST BE MOUNTED IN THE WATER LINES TO

THE EVAPORATOR TO ASSURE WATER FLOW BEFORE

STARTING THE UNIT

CHILLED WATER PIPING

The water flow entering the cooler must always be on the end

nearest the expansion valves and cooler refrigerant connec-

tions to assure proper expansion valve operation and unit

capacity (see pages 16 thru 20).

Design the piping so that it has a minimum number of

changes in elevation. Include manual or automatic vent valves

at the high points of the chilled water piping, so that air can

be vented from the water circuit. System pressures can be

maintained by using an expansion tank or a combination

pressure relief and reducing valve.

All chilled water piping should be insulated to prevent con-

densation on the lines. If insulation is not of the self-contained

vapor barrier type, it should be covered with a vapor seal.

Piping should not be insulated until completely leak tested.

Vent and drain connections must extend beyond pro-

posed insulation thickness for accessibility.

Page 6

I

IM 508

Loading...

Loading...