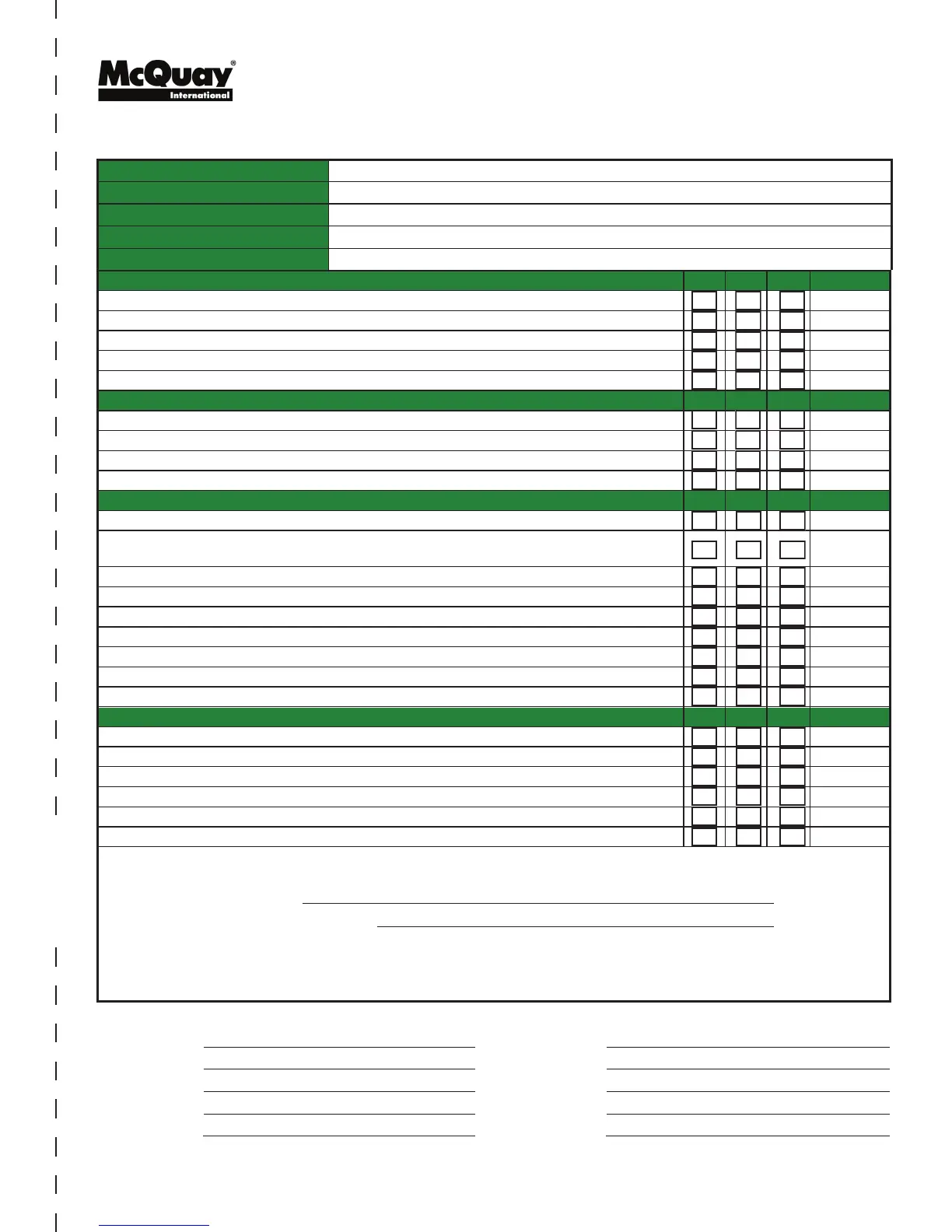

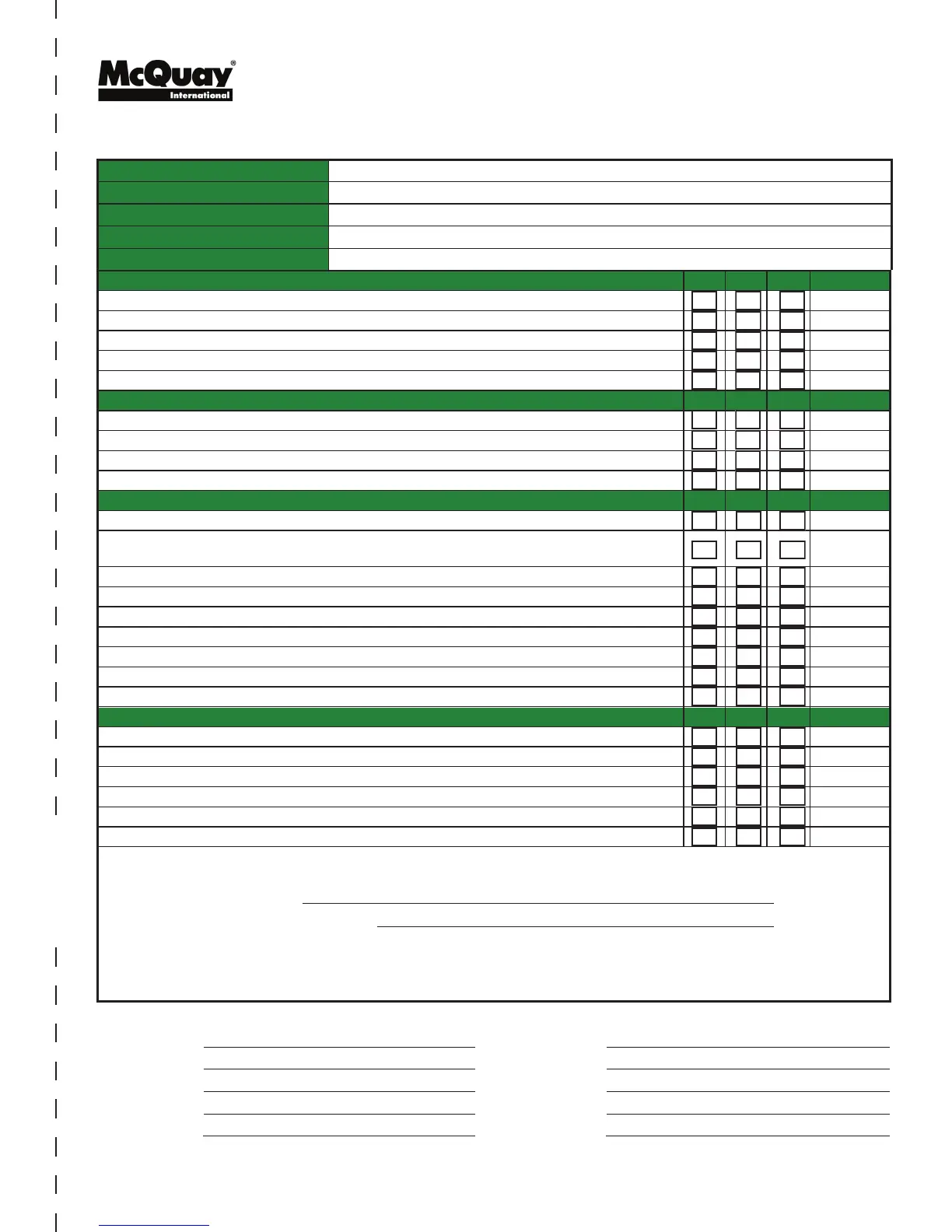

Pre-Start Checklist – Centrifugal Chillers

Must be completed, signed and returned to McQuay International service dept. at least 2 weeks prior to requested start date.

start date.

Water System – flushed, filled, vented; Water treatment in place

Pumps installed and operational (rotation checked, strainers installed and cleaned)

Controls operational (3-way valves, face/bypass dampers, bypass valves, etc.)

Water system operated and tested; flow meets unit design requirements

Cooling tower flushed, filled, vented; Water treatment in place

Pumps installed and operational (rotation checked, strainers installed and cleaned)

Controls (3-way valves, bypass valves, etc.) operable per IM/IOM

Water system operated and flow balance to meet unit design requirements

115 volt service completed, but not connected to control panel (remote mouned starters)

Line Power Leads connected to starter; load leads(b) run from starter to compressor, ready for

connection by Service (Do not connect load leads to starter or compressor terminals). (

See Notes 1 & 4)

All interlock wiring complete and compliant with McQuay International specifications

Starter complies with McQuay International specifications

*Oil cooler solenoid wired to control panel as shown on wiring diagram

(See Notes)

Pump starter and interlocks wired

Cooling tower fans and controls wired

Wiring complies with National Electrical Code and local codes

(See Note 4)

Condenser pump starting relay (CP1,2) installed and wired (See Note 3)

*Oil cooled water piping complete. (Units with water-cooled oil coolers only)

Relief valve piping complete (per local codes)

Thermometers, wells, gauges, control, etc., installed

Minimum system load of 80% capacity available for testing/adjusting controls

Document Attached: Technical Breakdown from Daikin Tools

Document Attached: Final Order Acknowledgement

Notes: The most common problems delaying start-up and affecting unit reliability are:

1. Field installed compressor motor power supply leads too small. Questions: Contact the local McQuay International sales representative. State size, number and

type of conductors and conduits installed:

a. From Power supply to starter

b. From starter to chiller unit (remote mounted)

2. Centrifugal chillers with water cooled oil coolers must have a 115 volt normally closed water solenoid valve installed in the oil cooler water supply line. Daikin

Applied recommends ASCO Type 8210B27 solenoid valve or approved equal and 40-mesh strainer. Daikin Applied does not supply these components.

3. A 115-volt field-supplied relay (CP1,2) must be used to start/stop condenser water pump on most applications. Cold condenser water must not flow through

condenser during compressor off cycle. Provisions have been made in control center for connecting CP relay, but must not have a rating in excess of 100 VA.

4. Refer to NEC Article 430-22 (a) *Does Not Apply to Magnetic Bearing Chillers (WMC/WME)

Contractor Representative

McQuay International Sales Representative

©2014 Daikin Applied Form SF01017 05AUG2014

Cut Here

Loading...

Loading...