MaInTenanCe

IOM 1210-1 • MAGNITUDE

®

MODEL WMC CHILLERS 60 www.DaikinApplied.com

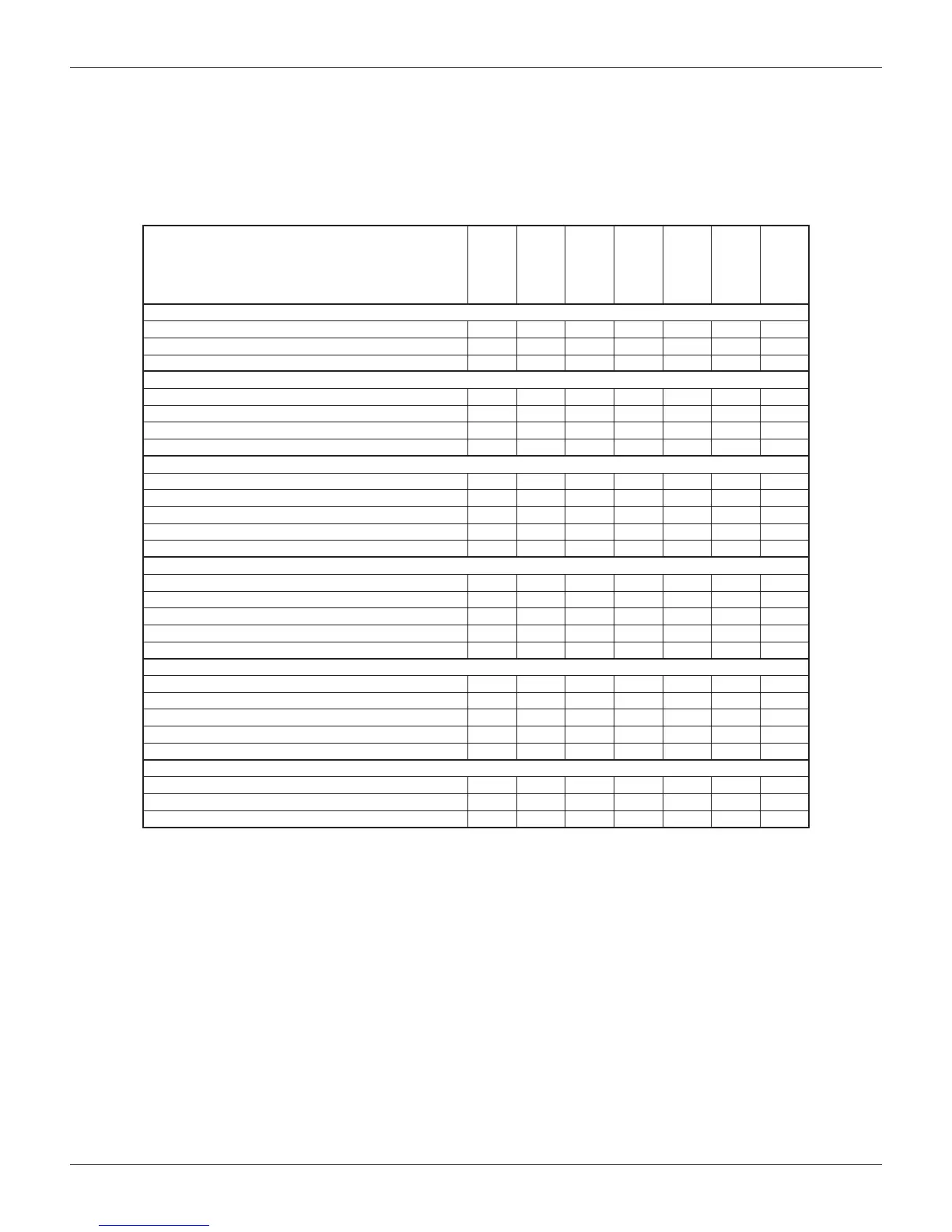

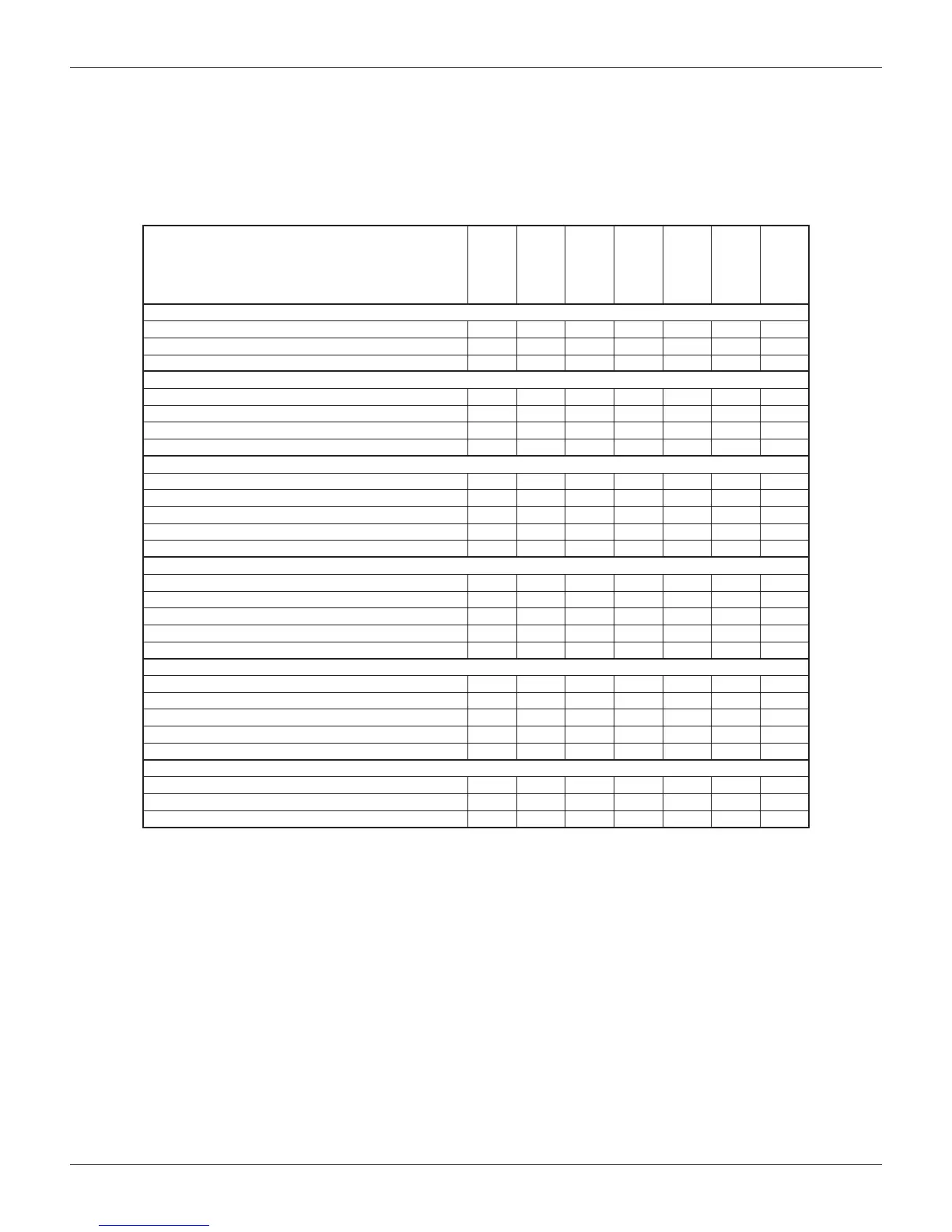

Maintenance Schedule

Table 25 provides an overview of recommended maintenance procedures along with how frequently these procedures should be

performed.

Table 25: Recommended Maintenance Schedule

Monthly

Quarterly

Semi-

Annually

Annually

As Required

By

Performance

During

Seasonal

Shutdown

During

Seasonal

Startup

I. Compressor

A. Analyze Compressor Fault Log X

B. Check IGV operation X

D. Check and tighten compressor electrical connections X

II. MicroTech

®

II Controls

A. Check for proper settings X

B. Verify transducers and sensors for accuracy X

C. Retrieve and archive OITS Trend Logs O

D. Perform MicroTech

®

II check, log, and last fault analysis X

III. Condenser

A. Conrm correct water ow and pressure drop O X

B. Conrm appropriate water treatment O

C. Clean and Leak Test condenser tubes X X X

D. Eddy Current Test - tube wall thickness X

E. Seasonal Protection X

IV. Evaporator

A. Conrm correct water ow and pressure drop O X

B. Conrm appropriate water treatment O

C. Clean and Leak Test evaporator tubes X

D. Eddy Current Test - tube wall thickness X

E. Seasonal Protection X

V. Chiller Unit

A. Run Test / Performance Evaluation X

B. Leak Test entire unit X X X

C. General Appearance:

1. Paint / Corrosion X

2. Insulation X

VII. Electrical

A. Check and record line voltage X

B. Inspect power components for signs of overheating X

C. Check and tighten unit electrical components X X

Key: O = Performed by in-house personnel X = Performed by qualied service personnel

Loading...

Loading...