Functional Description of EGM

_____________________________________________________________________

Status September 2003 (EvoBus-Service / AFT) Page: 37 of 83

2.5.3 Lambda control

The M 447 hLAG is a lean engine with lambda control. The lambda controller integrated in the EGM is

responsible for compliance with the pre-programmed target lambda in all engine operating points. During

idling the target lambda is equivalent to approx. 1.2, however is changed by the EGM in dependence on

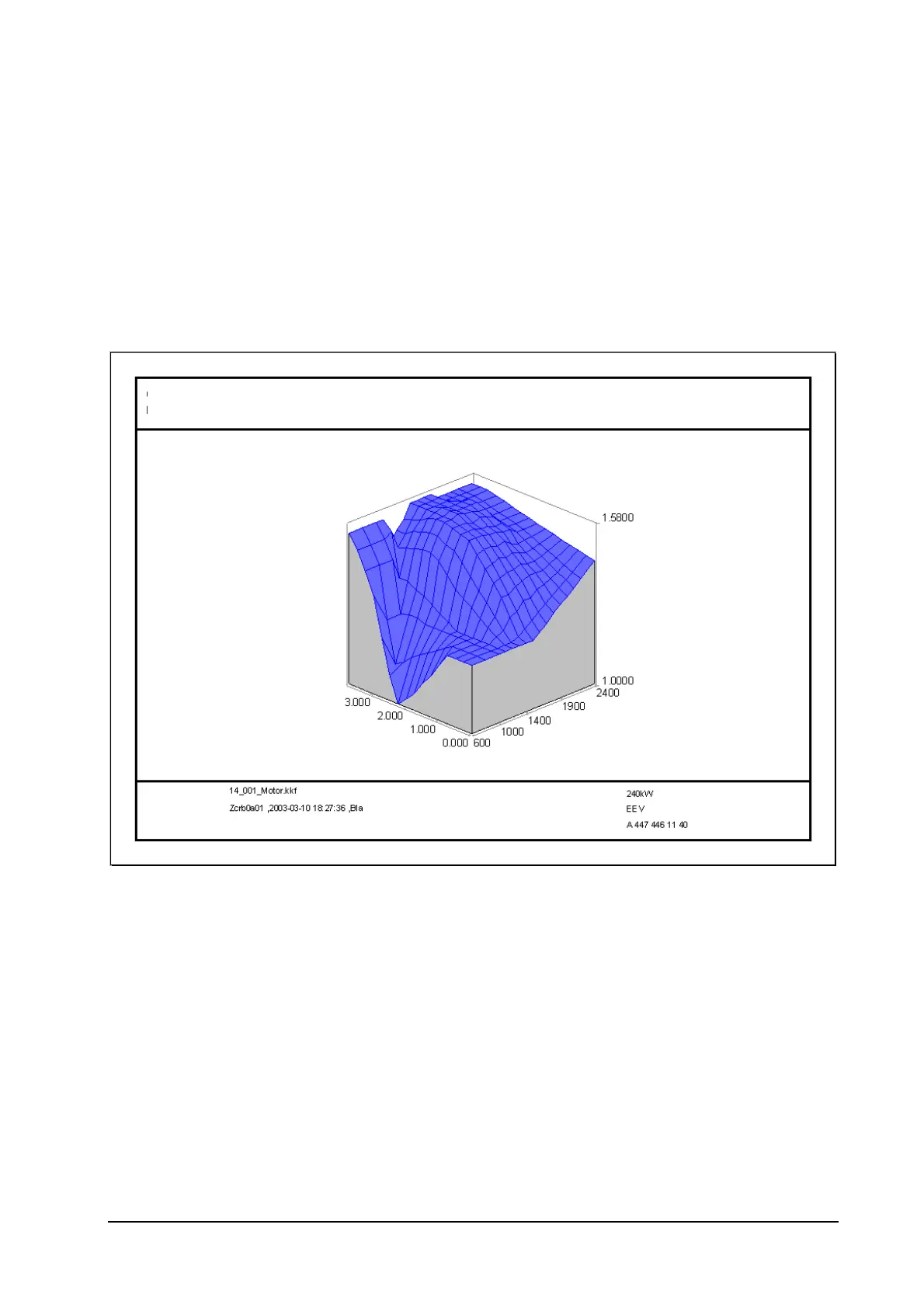

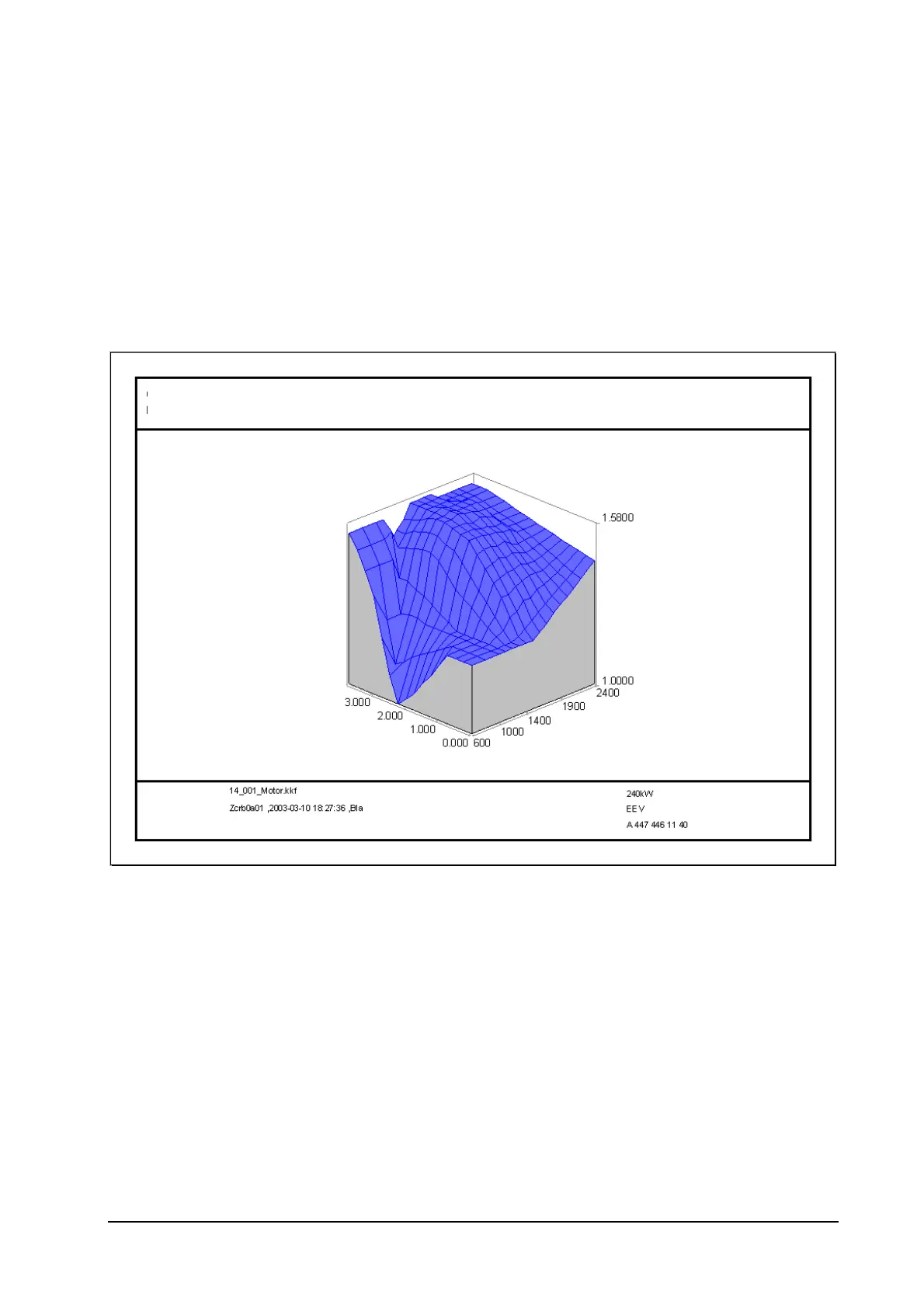

the control deviation by up to ± 0.2 as needed. The target lambda in partial-load operation is dependent

on the engine speed and the air mass. The target lambda lies in the range of approx. 1.1 to 1.6.

Target lambda in partial-load operation

To measure the real actual lambda, a lambda probe (broadband probe) is integrated in the exhaust

system between the turbocharger and the catalyst. Input variables of the lambda controller are the target

lambda and the actual lambda. The lambda controller supplies the lambda correction factor. This is

integrated in the calculation of the gas mass. As a result, the lambda controller can ensure compliance

with the target lambda by correcting the injected gas mass. A positive lambda correction factor means

that – always starting from the target lambda dependent on the operating point – the combustion is too

lean so that the engine control must inject gas as a reaction. Conversely, a negative lambda correction

factor means that the combustion is too rich, i.e. too much gas is injected.

GAP - Basic adjustment (LOW-gas)

Factor injection (LOW-gas) [.] = f(Speed[rpm], filled air mass [g/stroke]

Speed

Air mass

Loading...

Loading...