20

90-10212R40

GB

oh

MAINTENANCE

oha4

OUTBOARD CARE

To keep your outboard in the best operating condition, it is important that your

outboard receive the periodic inspections and maintenance listed in the Inspection

and Maintenance Schedule. We urge you to keep it maintained properly to ensure

the safety of you and your passengers and retain its dependability.

WARNING

Neglected inspection and maintenance service of your outboard or at-

tempting to perform maintenance or repair on your outboard if you are

not familiar with the correct service and safety procedures could cause

personal injury, death, or product failure.

Record maintenance performed in Maintenance Log at the back of this book. Save

all maintenance work orders and receipts.

SELECTING REPLACEMENT PARTS FOR YOUR

OUTBOARD

We recommend using original Mercury Precision or Quicksilver replacement parts

and Genuine Lubricants.

WARNING

Using a replacement part that is inferior to the original part could result

in personal injury, death, or product failure.

a

c

d

b

e

oti6

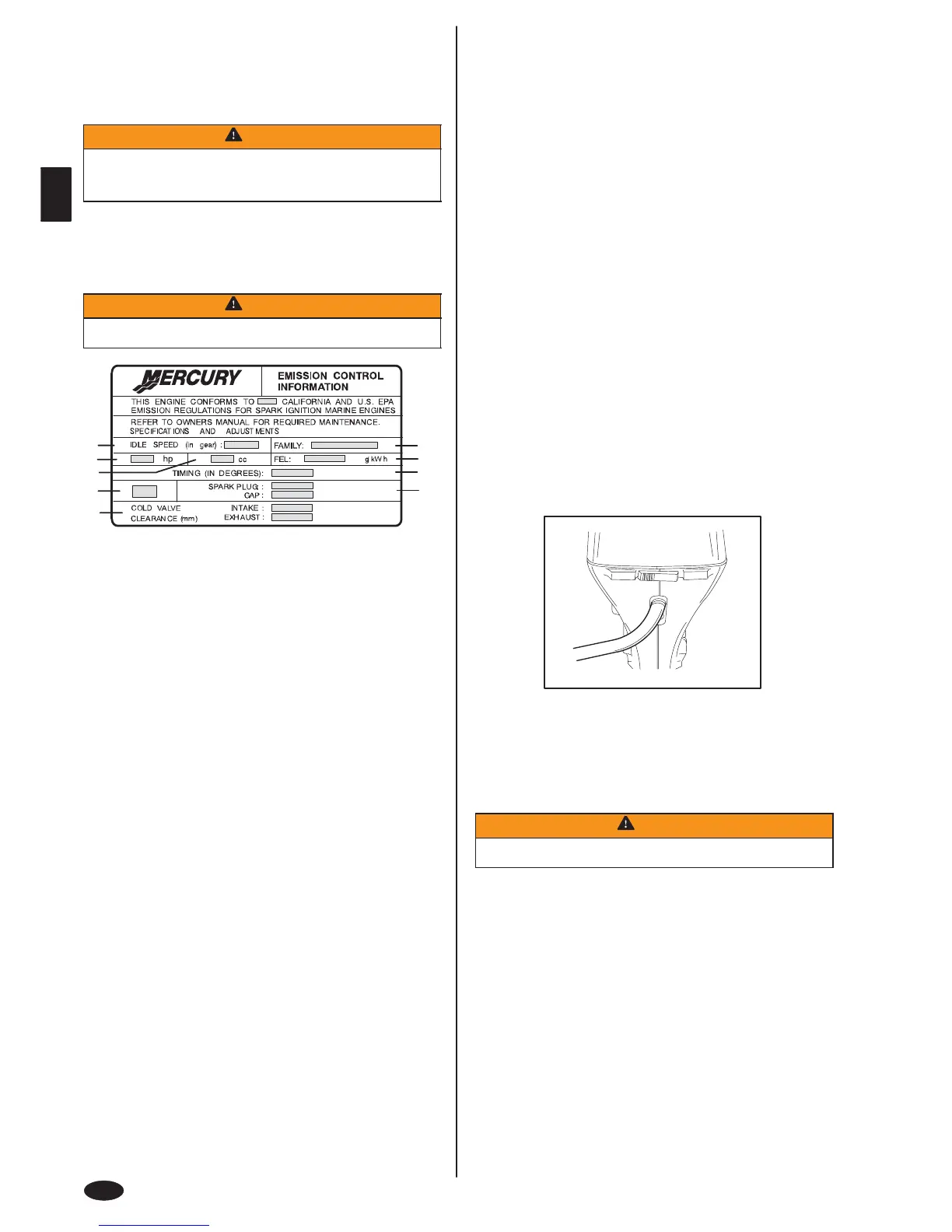

EMISSION CERTIFICATION LABEL

An emission certification label, showing emission levels and engine specifications

directly related to emissions, is placed on the engine at time of manufacture.

a.Idle Speed

b.Engine Horsepower

c.Piston Displacement

d.Date of Manufacture

e.Valve Clearance (if Applicable)

f. Family Number

g.Maximum Emission Output for

the Engine Family

h.Timing Specification

i. Recommended Spark Plug & Gap

oti7

OWNER RESPONSIBILITY

The owner/operator is required to have engine maintenance performed to maintain

emission levels within prescribed certification standards.

The owner/operator is not to modify the engine in any manner that would alter the

horsepower or allow emissions levels to exceed their predetermined factory

specifications.

ohd50

INSPECTION AND MAINTENANCE SCHEDULE

Before Each Use

1. Check engine oil level. (page 43)

2. Check that lanyard stop switch stops the engine.

3. Visually inspect the fuel system for deterioration or leaks.

4. Check outboard for tightness on transom.

5. Check steering system for binding or loose components.

6. Visually check steering link rod fasteners for proper tightness. (page 82)

7. Check propeller blades for damage.

After Each Use

1. Flush out the outboard cooling system if operating in salt or polluted water.

(page 78)

2. Wash off all salt deposits and flush out the exhaust outlet of the propeller and

gear case with fresh water if operating in salt water.

INSPECTION AND MAINTENANCE SCHEDULE

(CONTINUED)

Every 100 Hours of Use or Once yearly, Whichever occurs first

1. Lubricate all lubrication points. Lubricate more frequently when used in salt

water. (page 91)

2. Change engine oil and replace the oil filter. The oil should be changed more

often when the engine is operated under adverse conditions such as extended

trolling. (page 93)

3. Replace spark plugs at first 100 hours or first year. After that, inspect spark

plugs every 100 hours or once yearly. Replace spark plugs as needed. (page

88)

4. Inspect thermostat visually for corrosion and broken spring. Make sure

thermostat closes completely at room temperature.*

5. Check engine fuel filter for contaminants. (page 80, 81)

6. Check engine timing setup.*

7. Check corrosion control anodes. Check more frequently when used in salt

water. (page 83)

8. Drain and replace gear case lubricant. (page 95, 97)

9. Lubricate splines on the drive shaft.*

10.Check and adjust valve clearance, if necessary.*

11. Check power trim fluid. (page 92)

12.Inspect battery. (page 88)

13.Check control cable adjustments.*

14.Inspect timing belt. (page 90)

15.Check tightness of bolts, nuts, and other fasteners.

Every 300 Hours of Use or Three Years

1. Replace water pump impeller (more often if overheating occurs or reduced

water pressure is noted).*

Before Periods of Storage

1. Refer to Storage procedure. (page 99)

* These items should be serviced by an authorized dealer.

goh88

1-5

ohe5

FLUSHING THE COOLING SYSTEM

Flush the internal water passages of the outboard with fresh water after each use

in salt, polluted or muddy water. This will help prevent a buildup of deposits from

clogging the internal water passages.

IMPORTANT: The engine must be run during flushing in order to open the

thermostat and circulate water through the water passages.

Note: You can have the outboard tilted or in the vertical operating position during

flushing.

WARNING

To avoid possible injury when flushing, remove the propeller. Refer to

Propeller Replacement.

1 Place the outboard in either the operating position (vertical) or in a tilted

position.

2 Remove propeller (refer to Propeller Replacement).

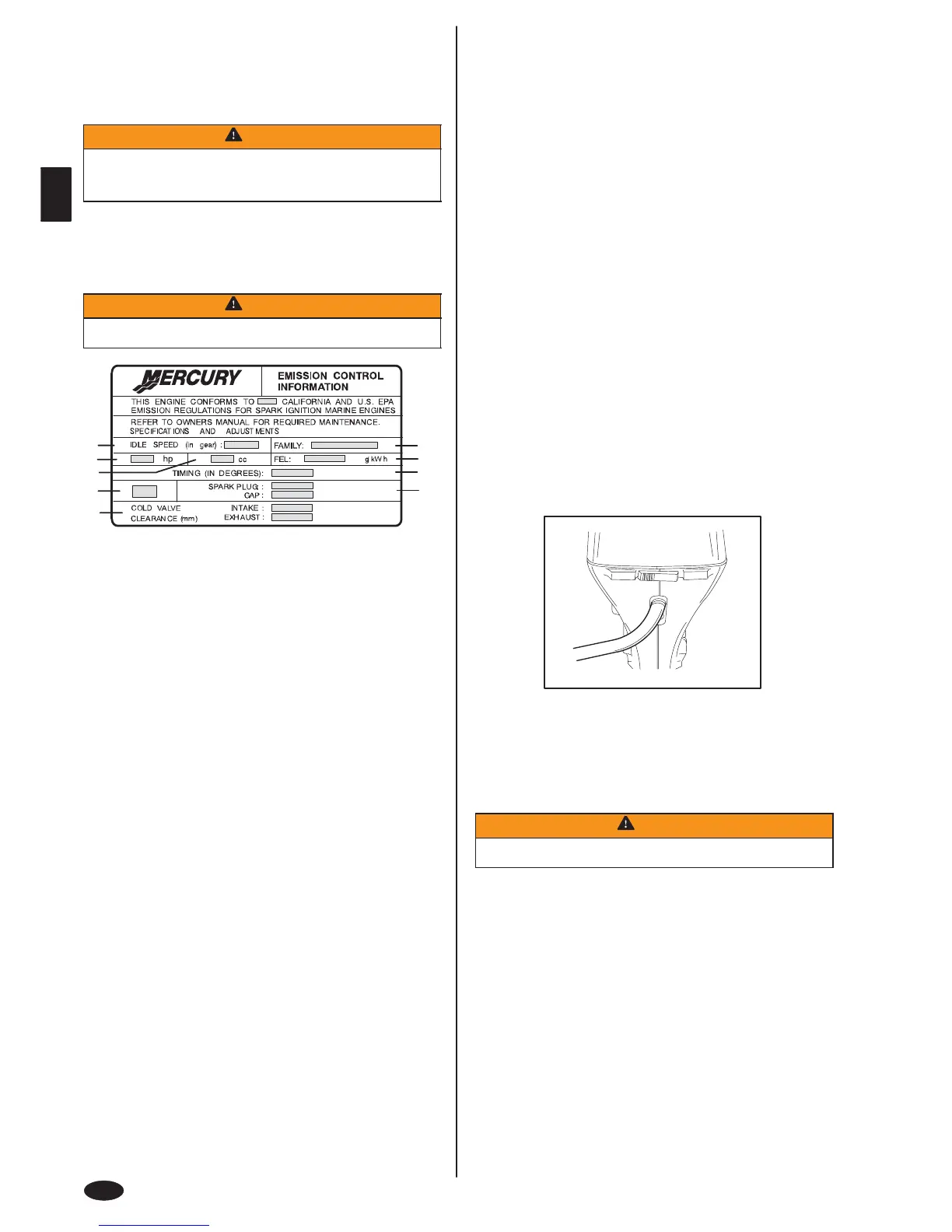

3 Thread a water hose into the rear fitting. Partially open the water tap (1/2

maximum). Do not open the water tap all the way, as this allows a high pressure

flow of water.

IMPORTANT: Do not run engine above idle when flushing.

4 Shift outboard into neutral. Start the engine and flush the cooling system for at

least 5 minutes. Keep engine speed at idle.

5 Stop the engine. Turn off the water and remove hose. Reinstall the propeller.

Loading...

Loading...