3. Lubricate the following with Quicksilver or Mercury Precision Lubricants

Extreme Grease or 2‑4‑C with PTFE.

Tube Ref

No.

Description Where Used Part No.

95

2-4-C with PTFE Propeller shaft 92-802859A 1

Extreme Grease Propeller shaft 8M0071842

•

Propeller Shaft ‑ Refer to Propeller Replacement for removal and

installation of the propeller. Coat the entire propeller shaft with

lubricant to prevent the propeller hub from corroding to the shaft.

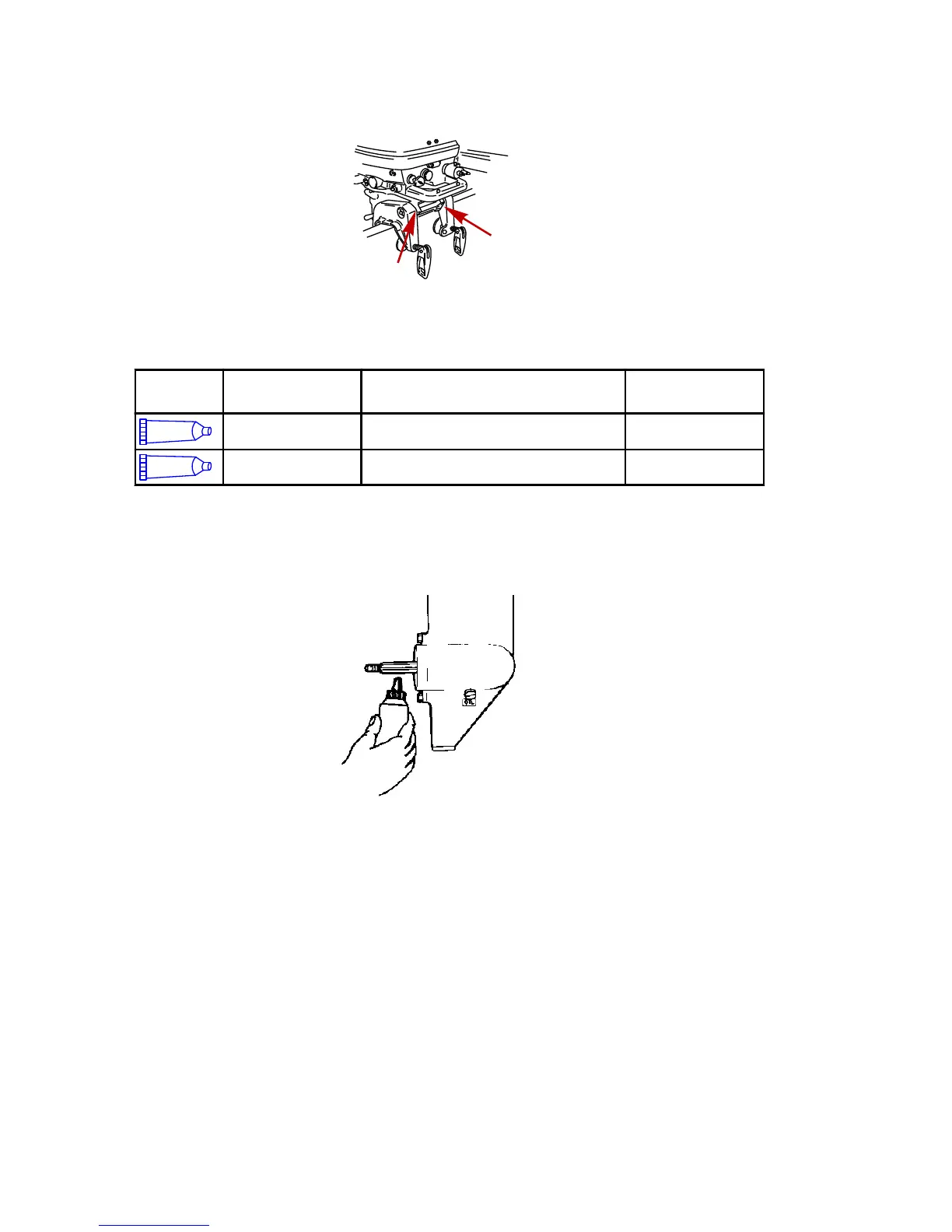

Gearcase Lubrication

When adding or changing gearcase lubricant, visually check for the presence of

water in the lubricant. If water is present, it may have settled to the bottom and

will drain out prior to the lubricant, or it may be mixed with the lubricant, giving it

a milky colored appearance. If water is noticed, have the gearcase checked by

your dealer. Water in the lubricant may result in premature bearing failure or, in

freezing temperatures, will turn to ice and damage the gearcase.

Examine the drained gearcase lubricant for metal particles. A small amount of

metal particles indicates normal gear wear. An excessive amount of metal

filings or larger particles (chips) may indicate abnormal gear wear and should

be checked by an authorized dealer.

MAINTENANCE

46 eng

Loading...

Loading...