7 NE 72 en 9

4 PRELIMINARY ACTIONS FOR THE

ADJUSTMENT

Set the valve's open and closed limits with the actuator lim-

iter screws; see the valve instruction manual. The changeo-

ver piece (46), the cam (29) and the internal feed-back

spring (40) must be in correct positions. Check the pilot

valve size from Table 2.

The adjustment must always be carried out when the sup-

ply pressure has been changed.

Please note that operating of the valve is required during

the adjustment.

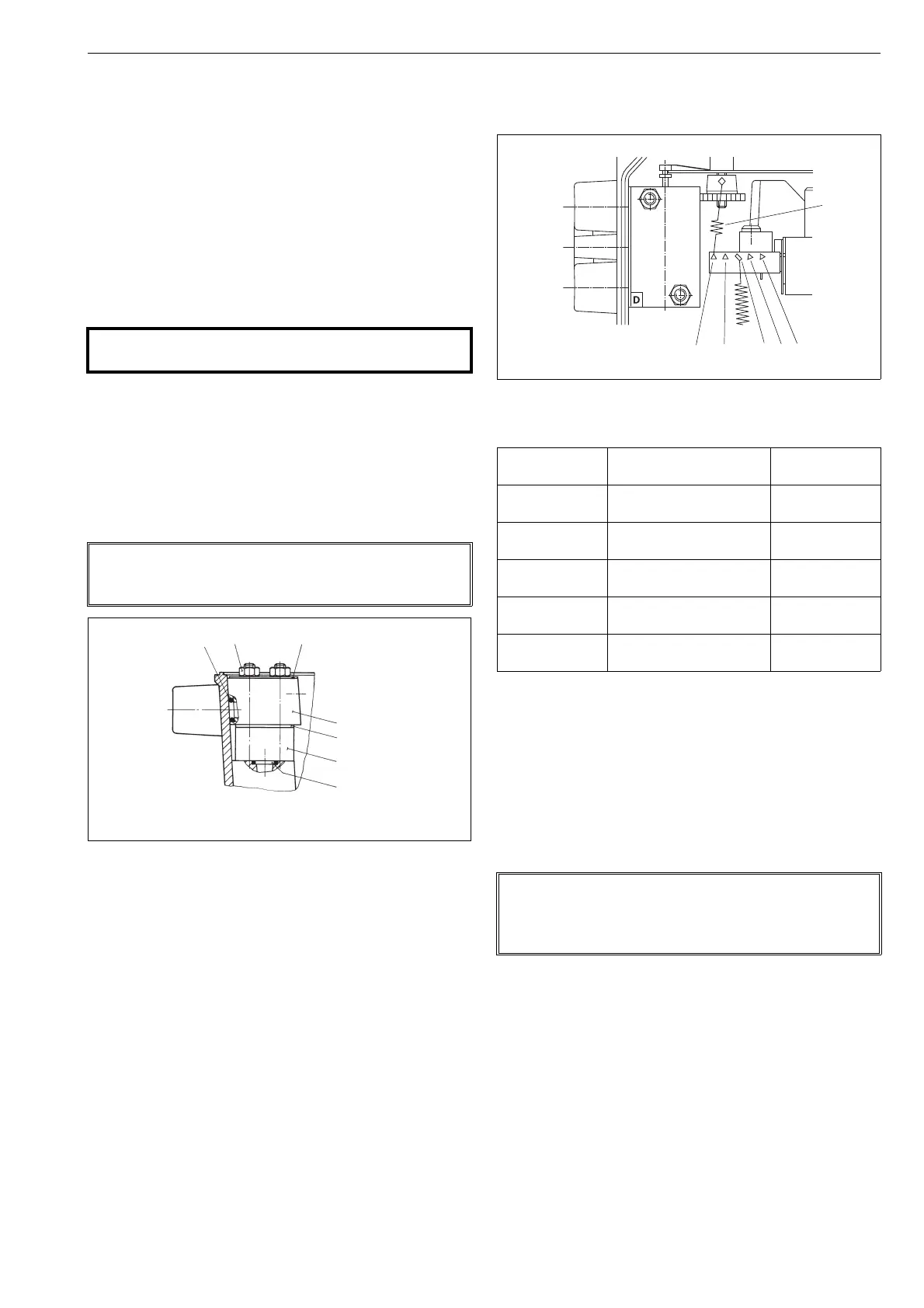

4.1 Position of the changeover piece

Choose the position of the changeover piece, D or R, from

Fig. 6 in accordance with the function desired.

Turn the changeover piece (46) when necessary.

Loosen the nuts (49) and remove the protective plate (48).

Pull out the changeover piece (46). Check the O-rings (47,

2 pcs.) and apply silicone grease lightly if needed. Place the

changeover piece (46) and the protective plate (48) in the

case. Tighten the nuts (49) evenly, one after the other.

4.2 Pilot valve

Removal of the pilot valve is unnecessary when the change-

over piece is turned around. For instructions of removal, see

Section 8.2.

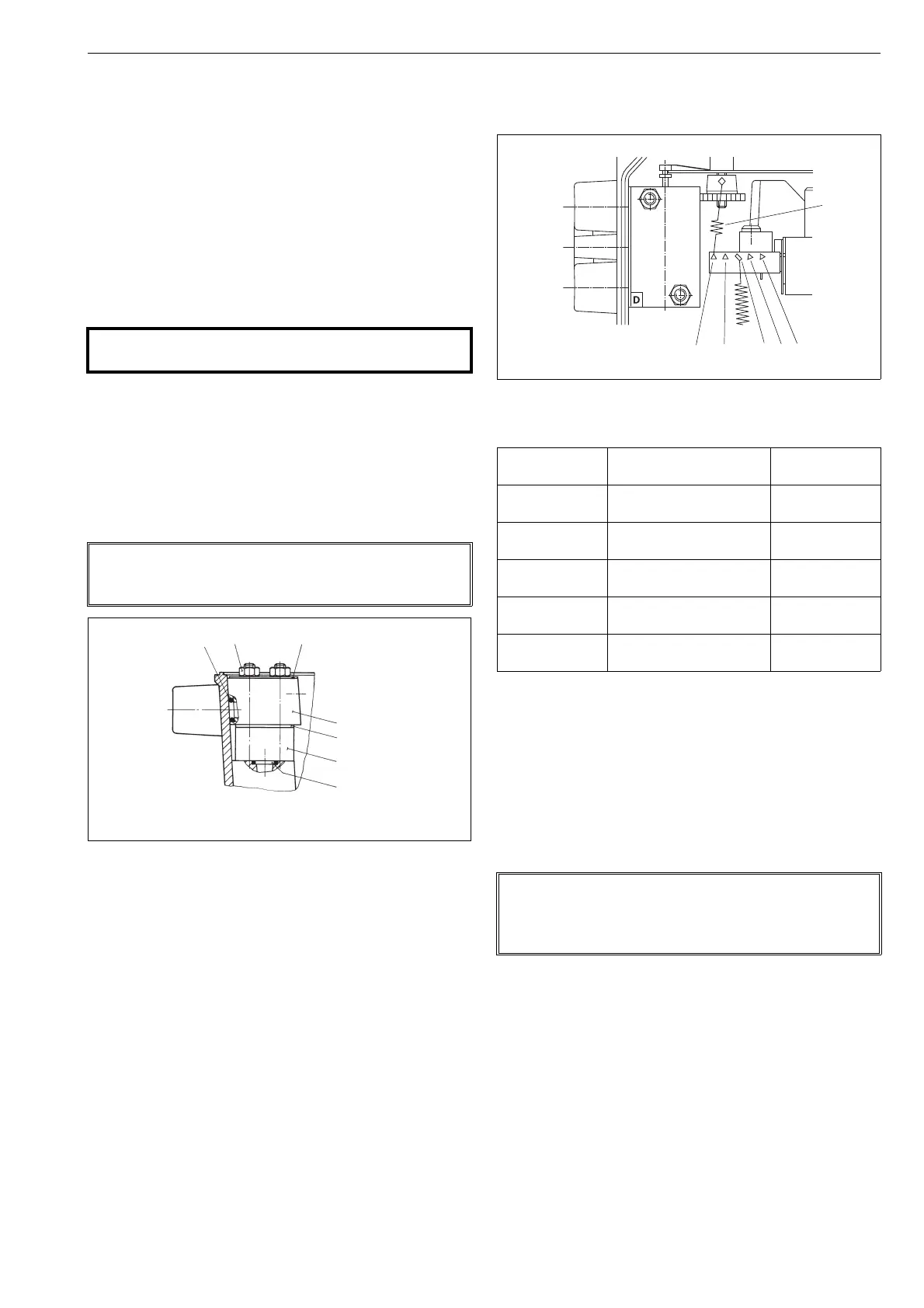

4.3 Setting the internal feed-back spring

Select the position for the lower end of the spring (40) from

Table 3 in accordance with the actuator size. The spring set-

ting must be made before the zero adjustment of the posi-

tioner, as it affects the adjustment.

The amplification of the positioner increases as the spring

(40) is moved from position 'a' to position 'e'.

If in the field the valve overshoots, the spring (40) can be

moved to the 'a' direction. If the valve goes into position too

slowly the spring can be moved to the 'e' direction respec-

tively.

In sticker inside the cover (2) has also been shown the posi-

tion for the lower end of the spring (40) in accordance with

the actuator size.

4.4 Position of the cam plate

Choose the side, A or B, and the rising segment of the cam

plate from Fig. 6 in accordance with the function desired.

Move the actuator piston to the end where the input signal

has its lower value. Shut off the supply pressure or move the

pilot spool by deflecting the balance beam (164) gently so

that the piston strokes to the desired limit. The input signal

should be zero or at the lower limit.

Loosen the screw (57), remove the indicator (32), loosen the

screw (31) and the locking wheel (30). Turn the cam plate

(29) to the desired side.

In case of α

0

adjustment, proceed acc. to Sections 6.1 and

6.2.

Place the roller so that its contact point is 1 mm from the

beginning of the rising segment. Then tighten the locking

wheel (30) and the screw (31).

CAUTION:

Do not dismantle a pressurized positioner!

NOTE:

Check that the changeover piece is mounted correctly:

Symbol D or R is visible in the lower left hand corner.

Fig. 9 Mounting the changeover piece

Fig. 10 Setting the internal feed-back spring

Table 3 Setting the internal feed-back spring

Spring (40)

setting

Actuator size

Cylinder volume

dm

3

a B1C 6, 8, B1J 6

QP 1

<0,5

b B1C 9, 11, 12; B1J 8

QP 2 (QP 1 *)

0,5...1

c B1C 13, 16; B1J 10, 12

QP 3 (QP 2 *)

1...4

d B1C 17, 20, 25; B1J 16

QP 4, QP 5 (BJ 8 *)

4...11

e B1C 32, 40; B1J 20, 25

B1C 50, 502; B1J 32, 322

11...50

*) NE729S positioner, (Obsolete since 2013).

NOTE:

Don't move the pilot spool by deflecting the beam (5).

The double diaphragm keeps the beam steadfast in the

position.

Loading...

Loading...